The fire pump is mainly a kind of pump equipment used for fire emergency

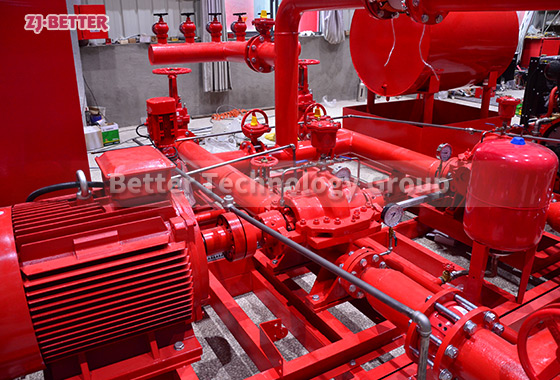

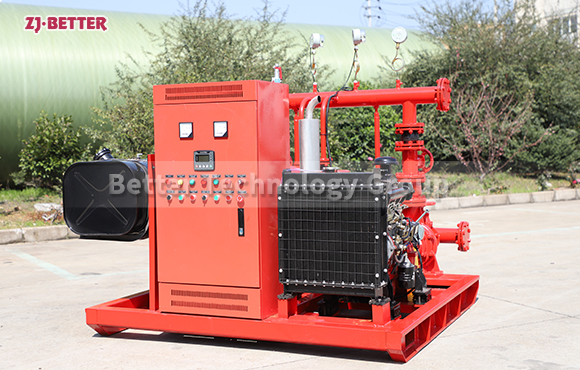

The fire pump is mainly a kind of pump equipment used for fire emergency, and its function is to transport the water source to the fire scene for fire fighting. In life, fire pumps are widely used in various buildings, such as factories, docks, warehouses, ports and other places, and are important equipment for fire emergency.

Fire pumps are widely used. Of course, the most important ones are used in the fire protection industry. They are also used in water treatment, environmental protection industries and so on. Among these uses, the fire protection industry uses the most. The fire protection industry has made full use of the advantages of fire pumps, which is the advantage of fast water pumping. Because most of the work in the fire protection industry is to put out fires, fire pumps play a very important role.