Essential Upgrade for Fire Systems: High-Flow Diesel Pump Sets for Rapid Fire Suppression

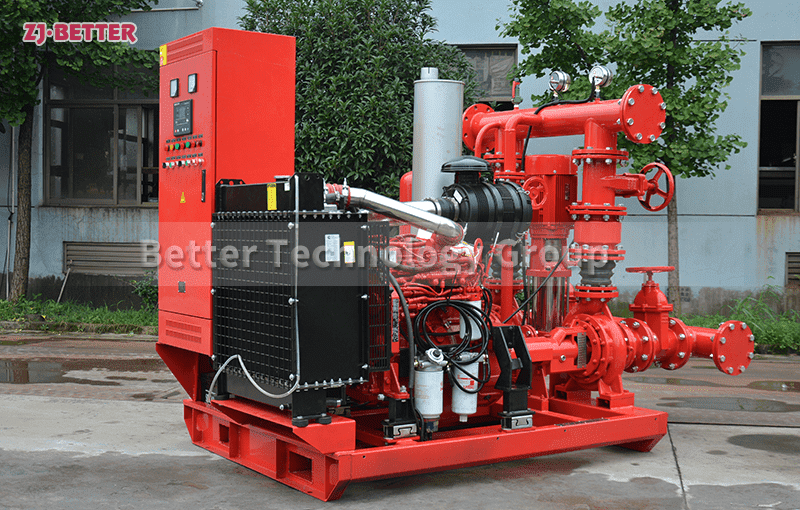

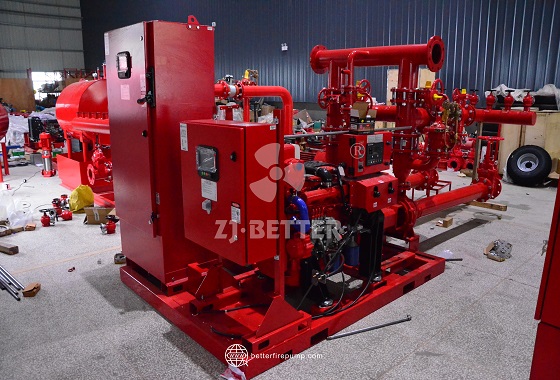

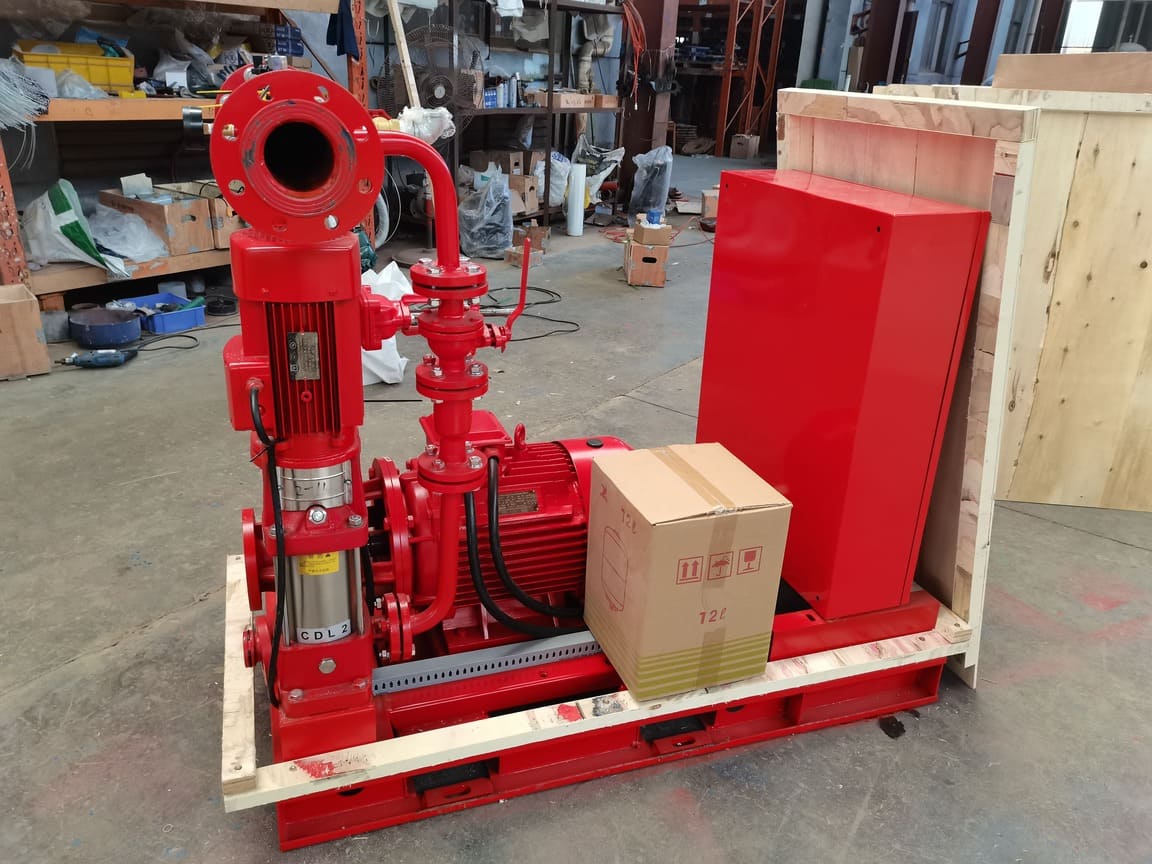

High-flow diesel pump sets have become the core equipment of fire protection systems with their strong power, high head and stable water supply performance. They have the advantages of fast start-up, automatic control and independent operation. They can continue to supply water even in power outages or harsh environments. They are widely used in high-rise buildings, industrial plants, oil and gas facilities and municipal projects, providing reliable protection for emergency firefighting.

As an indispensable core power unit in modern firefighting systems, high-flow diesel pump sets are widely used in large buildings, industrial plants, storage bases, oil and gas chemical facilities, and municipal infrastructure due to their excellent performance, reliable operation, and robust emergency water supply capabilities. Powered by a diesel engine, these pump sets utilize efficient pumping components to achieve robust flow output. They can operate independently even in power outages or harsh environments, ensuring continuous water supply to firefighting systems at critical moments and providing the most reliable support for firefighting. The key advantage of high-flow diesel pump sets lies in their adaptability and stability. Designed in accordance with international firefighting standards, they feature a compact structure and a well-organized layout, enabling rapid startup and stable, continuous water pressure output. These units typically utilize a high-performance diesel engine as their core power source, coupled with a high-lift centrifugal pump or self-priming pump structure to ensure stable pressure and flow over long distances or for high-rise water supply. Whether used for long-distance water transport within industrial pipelines or for supplying high-rise sprinkler systems, these units can deliver flow rates of up to hundreds of cubic meters per hour, meeting firefighting needs in diverse scenarios. In terms of performance, high-flow diesel pump sets are typically managed through an automated control system. These systems are equipped with an intelligent control cabinet, pressure sensors, flow monitoring devices, and an automatic alarm system, enabling real-time monitoring of operating status. If the system detects a drop in water pressure or a power outage, the diesel engine automatically starts within a fraction of a second, driving the pump at high speed to immediately restore water supply and ensure the continued stability of the firefighting system. This automated response mechanism is particularly critical in the early stages of a fire, eliminating the time delays associated with manual operation and saving precious minutes in extinguishing the fire. High-quality, high-temperature and corrosion-resistant materials are used in the construction of these pump sets. The pump body is typically constructed of ductile iron or stainless steel, and the shaft seal is reinforced to ensure long-term, leak-proof and wear-resistant operation. The diesel engine utilizes turbocharging technology for more complete combustion and higher output power, ensuring high efficiency even under prolonged, high-load operation. The cooling system utilizes either air or water cooling to adapt to varying environmental conditions, ensuring stable operation even in hot, humid, or dusty conditions. Furthermore, high-flow diesel pump sets offer exceptional reliability and reliability. In environments without an external power source, it can operate independently on diesel power, ensuring sufficient water supply even in extreme situations such as power outages, explosions, and earthquakes. This feature makes it a critical component in emergency firefighting systems. The pump unit also supports multi-mode operation, enabling single-unit startup, coordinated startup, or standby startup to meet specific needs, greatly enhancing system flexibility and safety redundancy. To achieve a balance between high efficiency and low energy consumption, the pump unit’s design prioritizes optimized energy utilization. Precise fluid dynamics and flow path optimization reduce flow resistance, improve pump efficiency, and maximize water output per unit fuel consumption. Furthermore, the diesel engine utilizes an electronic fuel injection control system that adjusts fuel injection in real time, reducing fuel consumption and exhaust emissions. This meets environmental requirements and is suitable for use in environments with strict environmental regulations. Regarding installation and maintenance, the high-flow diesel pump unit features a modular base design, resulting in a compact layout and a small footprint, allowing for quick installation in fire engine rooms, pump rooms, or mobile platforms. The equipment undergoes rigorous performance testing and pressure calibration before shipment to ensure compliance with fire safety standards. The system offers low noise and vibration during operation, along with a long maintenance cycle. Operators only need to regularly check the fuel, lubricating oil, and cooling systems, ensuring years of efficient operation. The control system’s visual human-machine interface makes operation more intuitive, displaying key data such as pressure, speed, flow rate, and temperature in real time for easy monitoring and remote management. Compared to traditional electric pumps, high-flow diesel pump sets offer significant advantages in emergency water supply. While electric pumps become completely ineffective in the event of a power outage, diesel-powered systems are completely independent of the external power grid, enabling truly independent operation. Furthermore, the diesel engine’s superior instantaneous starting torque and high power output enable it to power large pumps into operation within seconds, ensuring sufficient water pressure for firefighting at the earliest stages of a fire. This is particularly critical in critical facilities such as large tank farms, ports, refineries, and power plants. High-flow diesel pump sets have a wide range of applications, ranging from fixed firefighting systems to mobile fire trucks or trailers, creating flexible emergency water supply units suitable for firefighting operations in areas without a fixed water source or with insufficient water pressure. This equipment can also be used in municipal water supply, agricultural irrigation, emergency drainage, and industrial cooling, demonstrating its multi-functional and multi-scenario practical value. In terms of comprehensive performance, the high-flow diesel pump set, with its high flow output, high head, fast start-up performance, and powerful power system, has become an irreplaceable core component in large-scale fire protection system designs. It not only meets stringent fire protection standards and emergency response requirements, but also offers multiple advantages such as energy saving, environmental protection, stability, and easy maintenance. For fire protection systems requiring long-term continuous water supply or long-distance water transmission, this equipment is the preferred solution for ensuring safe operation. It represents the advanced level of modern fire pump technology, achieving a perfect combination of industrialization, intelligence, and reliability. With the continuous improvement of fire safety standards and technological advancements in emergency equipment, high-flow diesel pump sets are becoming a key upgrade direction for fire protection systems in various industries worldwide. Their powerful performance and excellent reliability provide a solid guarantee for fire safety in various complex environments.