Continuous Water Supply: Diesel Engine-Driven Fire Pumps Ensuring High-Pressure Firefighting Needs

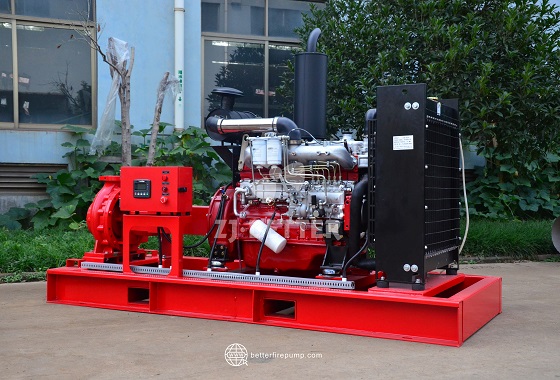

Diesel-engine-driven fire pumps provide uninterrupted water supply, high pressure, and high efficiency, making them suitable for a variety of complex environments. Their independent power system and energy-saving design ensure efficient firefighting and stable operation in emergency situations, making them a core component of fire emergency systems.

In the critical moments of a fire, time is the most precious resource in rescue efforts, and providing sufficient and continuous water support is crucial for extinguishing the fire. Traditional water supply equipment often fails to respond quickly or provide sufficient water flow, especially in large-scale fires or when high-pressure firefighting is required. Diesel-powered fire pumps, with their high efficiency and continuous water supply, are an ideal choice for meeting these intense firefighting demands. Diesel-powered fire pumps not only offer powerful water output but also operate independently in complex and extreme environments, ensuring stable operation even without power, and protecting firefighting and rescue efforts from external factors. Their reliability and continuity make them indispensable in firefighting systems.

First and foremost, one of the greatest advantages of diesel-powered fire pumps is their uninterrupted water supply. In firefighting, a stable and continuous water supply is essential for extinguishing fires. Especially in large-scale fires, the pressure and flow of water directly determine the speed and effectiveness of extinguishing the fire. Diesel-powered fire pumps are typically equipped with a high-efficiency diesel engine and pump system, capable of continuously providing a strong water flow at high pressure, meeting the requirements of high-pressure firefighting. Traditional electric fire pumps often rely on external power. Interruptions or instability in the power supply can disrupt water supply, severely impacting firefighting efforts. Diesel-powered fire pumps, on the other hand, rely on their independent power system to operate stably even without power, ensuring uninterrupted firefighting operations. This independent power system is a core advantage of diesel-powered fire pumps, particularly in post-disaster emergencies, remote areas, or harsh environments where power cannot be restored in a timely manner. Diesel-powered fire pumps offer strong water flow and high water pressure, enabling them to handle the demands of high-intensity firefighting. Depending on the application, diesel-powered fire pumps can be configured with pump systems of varying flow rates and water pressures to accommodate fires of all sizes. Whether tackling a large forest fire or a high-rise building blaze, diesel-powered fire pumps can provide an ample supply of water and deliver it to the fire scene at a stable pressure, ensuring precise coverage of the entire blaze area. Firefighting in high-rise buildings requires strong water pressure to overcome the flow resistance caused by the building’s height. Diesel-powered fire pumps, with their powerful power systems, can deliver a stable high-pressure water flow, ensuring unrestricted firefighting operations in high-rise buildings.

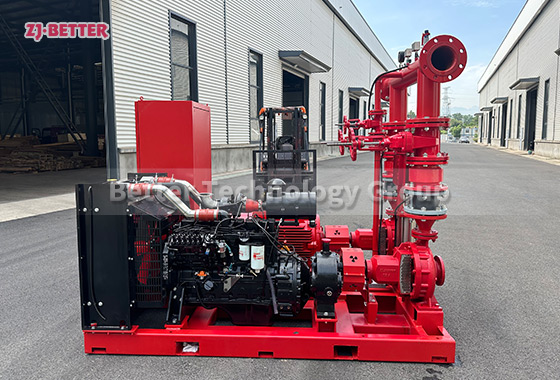

The flexibility and adaptability of diesel-powered fire pumps enable them to operate reliably in a variety of complex environments. Whether in densely populated urban high-rise buildings or in extreme conditions such as high temperature, cold, humidity, or dusty industrial environments, diesel-powered fire pumps maintain long-term, stable performance. The independence of diesel-powered fire pumps is particularly important in remote areas or emergency response sites, where power supply may be limited or interrupted. Not only do they overcome the limitations of power dependence, but they also allow for flexible configuration based on specific environmental needs. For example, in areas with complex terrain or a lack of fixed water supply infrastructure, diesel-powered fire pumps can be quickly deployed and provide firefighting water at temporary water points, ensuring that rescue operations can begin as quickly as possible.

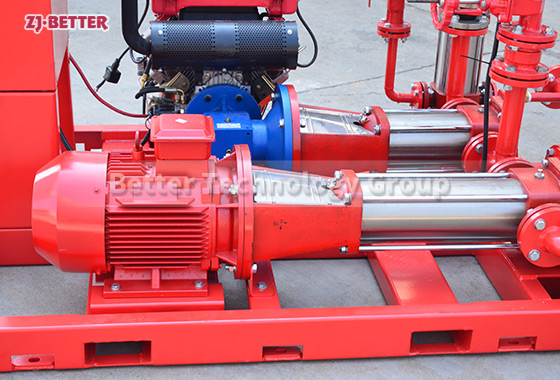

Compared to traditional fire pumps, diesel-powered fire pumps also excel in ease of operation and maintenance. Equipment design typically allows for efficient operation in emergency situations. Users can start and stop the pump and adjust parameters via a simple control panel. Diesel-powered fire pumps can be used smoothly even by personnel without specialized technical backgrounds. Furthermore, maintenance is simplified. Diesel-powered fire pump components typically utilize a modular design, reducing the complexity required for repairs. Regularly checking the oil level, cooling system, and cleaning the pump body are routine tasks that operators can quickly complete, significantly reducing maintenance time and costs.

Diesel-powered fire pumps also offer significant advantages in terms of durability and reliability. Fire pump units often operate under extreme weather conditions and high loads for extended periods, placing stringent demands on their durability. Diesel-powered fire pumps utilize high-strength materials and advanced protective designs to effectively withstand environmental corrosion and high loads, ensuring they can operate smoothly in harsh environments such as high temperature, high humidity, low temperature, and dust. The high reliability and durability of diesel-powered fire pumps make them a reliable guarantee of fire safety, particularly in specialized environments such as industrial sites, mining areas, and offshore platforms.

Furthermore, the energy-saving and environmentally friendly performance of diesel engine-driven fire pumps is increasingly recognized. Modern diesel engines are optimized for improved fuel efficiency, reduced energy consumption, and lower emissions. Although diesel engines rely on fuel for power, their efficient engines and optimized fuel systems ensure maximum fuel utilization, thereby reducing overall operating costs and environmental impact. The equipment’s low-emission design meets modern environmental standards and reduces air pollution. This eco-friendly design not only complies with national and regional environmental regulations but also helps reduce the long-term operating costs of firefighting equipment.

In summary, diesel engine-driven fire pumps, with their advantages of uninterrupted water supply, strong water pressure, high efficiency, adaptability, ease of operation, and low maintenance, have become an indispensable core component of modern fire emergency systems. Their efficient, stable, and reliable performance provides strong firefighting support in a variety of extreme environments, ensuring a continuous water supply for firefighting in emergency situations. Whether in urban high-rise buildings and industrial parks, or in remote areas and post-disaster emergency rescue sites, diesel engine-driven fire pumps can be put into operation in the shortest possible time, ensuring efficient and timely fire suppression. With the continuous advancement of technology, diesel engine-driven fire pumps will continue to play an important role in various firefighting scenarios and promote the continuous development of global fire safety technology.