Advantages of Vertical Multistage Fire Pump Sets in High-Rise Fire Protection Systems

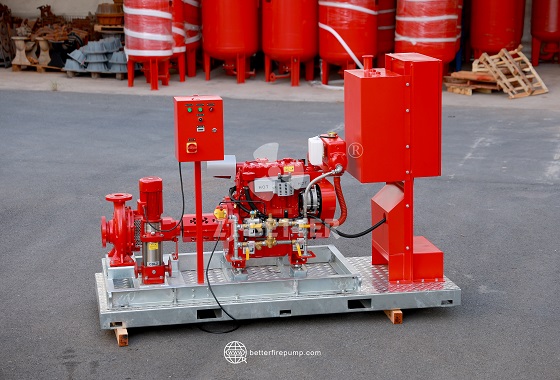

The high-efficiency vertical multistage fire pump unit is designed specifically for fire-fighting pressure-stabilized water supply systems in high-rise buildings. It features high head, small footprint, stable operation, rapid response, and convenient maintenance. It can operate reliably for a long time and meets the strict requirements of fire hydrant and sprinkler systems for pressure and flow. It is suitable for various fire-fighting applications such as commercial complexes, residences, hospitals, and industrial buildings.

The advantages of vertical multistage fire pump units in high-rise building pressure-stabilized water supply are mainly reflected in their structural design, operational performance, system adaptability, and long-term reliability. Especially in modern high-rise buildings, large commercial complexes, hospitals, data centers, and industrial plants—places with extremely high requirements for fire water supply stability and response speed—these products have become one of the core equipment in fixed fire protection systems. Vertical multistage fire pumps adopt a vertical structure, which, compared to traditional horizontal fire pumps, occupies less space and extends the equipment height upwards, effectively adapting to the limited space of pump rooms in high-rise buildings. It also facilitates direct connection to vertical fire protection pipe networks, reducing pipe bends and hydraulic losses, thus improving water supply efficiency at the system level. The multistage impeller series design allows the pump to achieve high overall head output even with a relatively small single-stage head, making it particularly suitable for applications in high-rise buildings with high static pressure in the fire protection pipe network and long water supply distances. It can continuously provide sufficient fire water pressure while ensuring stable flow, meeting the multiple needs of fire hydrant systems, sprinkler systems, and pressure stabilization systems. These types of fire pump units typically use high-strength cast iron or stainless steel as key flow-through components, possessing excellent pressure resistance, wear resistance, and corrosion resistance. They maintain stable hydraulic performance even under long periods of standby or frequent start-stop conditions, avoiding performance degradation due to material fatigue or corrosion, thus significantly extending equipment lifespan. Vertical multistage fire pumps undergo precise calculations and optimizations in their hydraulic design, with a reasonable fit between the impeller and guide vanes and smooth internal flow channels, effectively reducing hydraulic losses and operating noise. This ensures stable operation even under high loads, minimizing the impact of vibration on the unit and piping system, which is particularly important for high-rise buildings where environmental noise and equipment stability requirements are high. Regarding motor configuration, vertical multistage fire pumps are usually equipped with high-efficiency motors with excellent heat dissipation and overload capacity, enabling continuous operation for extended periods without overheating during fire emergencies. This ensures uninterrupted water supply during fires, buying valuable time for the fire protection system. Designed to address the characteristics of high-rise building fire protection pressure stabilization systems, vertical multistage fire pumps can be flexibly combined with pressure stabilizing devices, pressure tanks, control cabinets, and other components to form a complete pressure-stabilized water supply solution. During daily operation, this maintains stable pipeline pressure, preventing frequent starts of the main fire pump due to minor leaks or pressure fluctuations, thereby reducing system energy consumption and equipment wear. In the event of a fire, the main pump can quickly be put into operation, outputting the rated flow and head under design conditions, ensuring the overall reliability and response speed of the fire protection system. The structural design of this type of fire pump unit emphasizes ease of maintenance. The vertical layout makes axial disassembly and assembly more intuitive. Routine maintenance allows for the inspection and replacement of easily damaged components such as seals and bearings without extensive pipe disassembly, effectively reducing maintenance costs and downtime. This is particularly suitable for fire protection systems in high-rise buildings where continuous operation is crucial. To adapt to different building sizes and fire protection regulations, vertical multistage fire pumps offer high flexibility in model configuration. Customized selection can be made based on design flow rate, head, pipe diameter, and system pressure rating to meet the fire water supply needs of buildings of different heights and functions, while also facilitating future system upgrades or expansions. Its excellent system compatibility allows it to work with various automatic control systems. Through pressure sensors, liquid level monitoring, and remote control modules, it can achieve automatic start/stop, fault alarms, and operational status monitoring, improving the intelligence level of the fire protection system and reducing the risk of manual intervention. In practical applications, vertical multistage fire pumps, with their rapid start-up and fast pressure build-up, can raise the pipeline pressure to the design value in a very short time, effectively shortening the response time of the fire protection system. This is of great significance for controlling the fire in its early stages and reducing casualties and property losses. At the same time, the high efficiency and low energy consumption characteristics exhibited by this type of pump in long-term operation also help reduce the overall operating cost of the building, which is in line with the current trend of energy conservation and environmental protection. In summary, the application of vertical multistage fire pump units in the pressure-stabilized water supply system of high-rise buildings not only provides a reliable, stable, and efficient fire water source guarantee, but also shows significant advantages in space utilization, system stability, maintenance convenience, and intelligent management. It is an ideal choice for modern high-rise building fire protection systems that balances safety and economy.