Electric Motor Fire Pump System: Energy-Efficient Fire Protection for Urban Buildings

Explore the benefits of electric motor fire pump systems for urban buildings. Energy-efficient, low-maintenance, and ideal for high-rise fire protection with reliable and quiet operation.

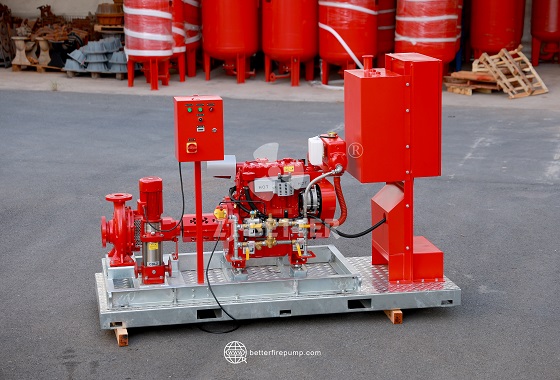

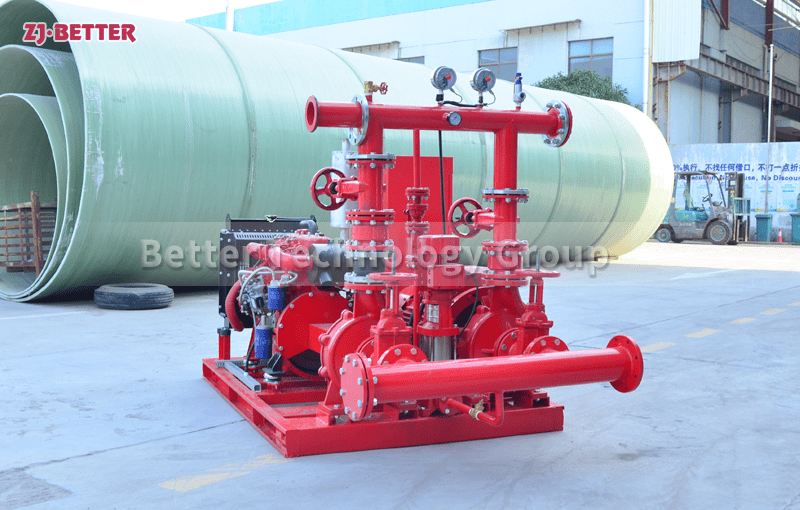

An electric motor fire pump system designed for urban buildings represents a modern, efficient, and reliable solution for fire suppression demands in densely populated environments. These systems are engineered with a focus on energy conservation, consistent performance, and operational stability to ensure that high-rise residential complexes, commercial facilities, hospitals, educational institutions, and government buildings remain protected under any emergency scenario. The core of this fire protection solution is a high-efficiency centrifugal pump driven by a robust electric motor, capable of providing steady water flow and pressure to sprinkler systems, hose reels, and standpipe systems across multiple floors without the delay or variability seen in manual or less advanced systems. One of the primary advantages of an electric motor fire pump system is its seamless integration with building power supplies, eliminating the need for fuel storage, exhaust systems, or ventilation associated with diesel-driven units. This contributes to both operational simplicity and environmental friendliness, making it ideal for indoor installations or noise-sensitive locations. Moreover, electric pumps operate with minimal vibration and low noise, ensuring that building occupants experience little to no disruption during routine testing or emergencies. These systems typically feature vertical or horizontal split-case pump configurations or end-suction and inline pumps, depending on the building’s layout and space constraints. Each system is carefully selected to match the building’s hydraulic requirements, including flow rate, head pressure, and elevation factors. Electric motors used in these systems are built to international standards such as IEC or NEMA, and are tested for continuous-duty operation under high load conditions, ensuring that the fire pump can function without overheating or stalling during extended emergency operations. The system also includes a fully integrated control panel, often mounted on a rigid steel skid alongside the pump and motor, forming a compact and efficient unit. This control panel is equipped with all the essential operational controls, status indicators, fault alarms, and emergency start features required to manage the pump automatically or manually. With modern advancements, these panels also offer smart connectivity options, allowing remote monitoring via IoT systems or integration with building management systems (BMS), making it easy for facility teams to oversee pump health, schedule routine maintenance, and conduct fire drill testing from a centralized control room. From an energy efficiency standpoint, electric motor fire pump systems stand out for their reduced energy consumption compared to traditional systems. By utilizing high-efficiency motors paired with optimized impeller and volute designs, the system reduces power wastage during start-up and normal operation. Some configurations may even include variable frequency drives (VFDs) for better soft-starting and load matching, though most fire protection standards require direct-on-line (DOL) or star-delta starting methods to ensure instant operation during emergencies. Additionally, the simplicity of electric systems translates into lower maintenance requirements. Unlike diesel systems, which need regular oil changes, fuel quality checks, battery replacements, and exhaust cleaning, electric pumps have fewer mechanical wear components, resulting in reduced downtime, lower service costs, and longer system lifespans. In many urban areas where utility power is stable and backup generators are already part of building infrastructure, electric motor fire pumps are the logical and most efficient choice. They not only reduce carbon emissions and noise pollution but also provide unmatched reliability due to their direct connection to the electrical grid and quick start-up response time. In high-rise buildings, pressure management becomes a challenge, but with a well-configured electric fire pump, water can be delivered to the upper floors with ease, maintaining required pressure levels throughout the riser system. The addition of pressure sensing feedback loops within the controller allows for better system response to dynamic demand changes during firefighting scenarios. Safety features of electric fire pump systems include overcurrent protection, short-circuit protection, phase failure alarms, and thermal sensors to detect overheating. These protections ensure that the motor and pump continue to function within safe parameters, extending the operational life of the entire system and reducing the risk of unplanned failure. Additionally, the pump assemblies are fabricated using corrosion-resistant materials, such as cast iron or bronze impellers, stainless steel shafts, and powder-coated components, which ensure durability even in humid or chemically aggressive environments such as basements or parking garages. Another advantage is the ease of installation. Electric motor fire pump systems come pre-assembled and pre-wired on steel bases, which simplifies transportation, positioning, and anchoring at the site. With detailed installation manuals and support for flexible pipe connections, building contractors can complete setup quickly and accurately. Commissioning procedures typically include insulation resistance tests, no-load runs, and full load performance tests, all of which are easier to perform with electric motors than with internal combustion engines. For property developers and facility managers looking to comply with fire codes and safety regulations, these systems are engineered and tested to meet the latest NFPA 20, UL, and FM global standards. This ensures not only peace of mind for building owners but also reduced insurance premiums due to the use of certified fire protection systems. In today’s climate-conscious world, electric fire pump systems also align with green building certifications such as LEED and BREEAM. Their energy-saving features and emission-free operation contribute positively to sustainability goals, making them ideal for projects pursuing ESG objectives. The system’s design flexibility allows it to be used as the main fire pump or as part of a multi-pump configuration including jockey pumps and standby pumps. Each component, from the motor to the valves, is selected for long service life and compliance with safety codes. Backup power options, such as automatic transfer switches or UPS-supported controllers, further enhance reliability in case of power fluctuations or outages. In summary, an electric motor fire pump system is a smart investment for modern urban buildings where space, efficiency, environmental compliance, and operational simplicity are critical. It provides reliable, quiet, and rapid water delivery during fire emergencies, while reducing energy costs and maintenance workload. With the right design and implementation, this system can serve as a cornerstone in a building’s life safety strategy, ensuring that when danger arises, the response is fast, effective, and fully compliant with the highest safety standards.