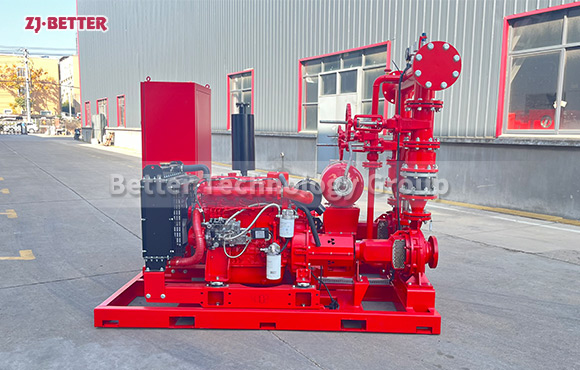

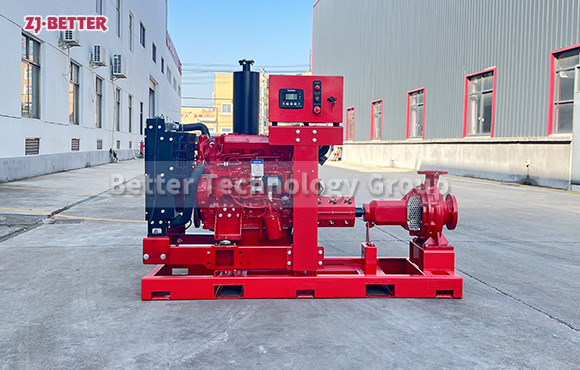

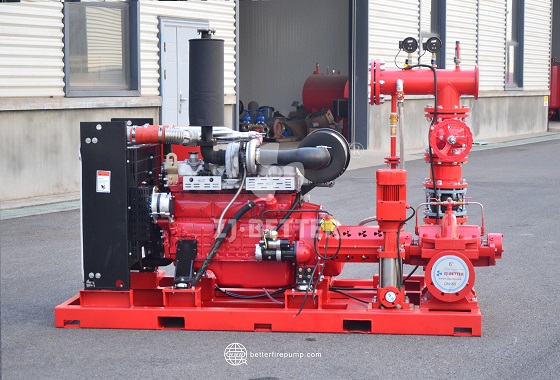

Heavy-Duty Fire Pump Power System for Long-Term Emergency Operation

The heavy-duty fire pump power system is designed for long-term emergency operation, featuring high torque output, stable power performance and efficient heat dissipation. It supports the fire pump to work continuously under high load conditions and is widely applicable to industrial, municipal and high-risk locations, comprehensively improving the reliability and safety of fire water supply systems.

Heavy-duty fire pump power systems are key equipment designed specifically for high-intensity, long-cycle firefighting operations. Their core function is to continuously and stably provide sufficient power support to fire pumps in emergencies such as fires, ensuring the fire water supply system maintains high efficiency throughout the entire firefighting process. These fire pump power systems are widely used in industrial plants, petrochemical plants, power facilities, large warehousing and logistics centers, mines, ports, airports, and key municipal projects where fire reliability requirements are extremely high. These environments often feature high fire risk, long firefighting times, and large water supply loads, placing more stringent demands on the equipment’s continuous operating capability, power output stability, and overall reliability. The heavy-duty design is one of the most significant advantages of this fire pump power system. Its power unit is selected with full consideration of continuous operation under high load conditions, possessing high torque output capability and good power reserves. Even when the fire pump is operating at full load, it can maintain stable speed and output performance, avoiding water pressure fluctuations or reduced water supply capacity due to insufficient power, thus effectively ensuring firefighting efficiency. The power system typically employs a reinforced chassis design, with key load-bearing components manufactured from high-strength materials. This results in high overall rigidity and excellent fatigue resistance, enabling it to withstand the mechanical stress and thermal loads of prolonged continuous operation, significantly extending the equipment’s service life. The cooling system is crucial for the long-term stable operation of heavy-duty fire pump power systems. It is usually equipped with efficient heat dissipation devices, effectively controlling the operating temperature of the power unit under high loads through optimized cooling ducts and heat exchange structures. This prevents performance degradation or shutdown due to overheating, ensuring the power system remains in a safe and reliable operating state throughout continuous firefighting operations. The fuel and power supply system also emphasizes stability and safety in its design. Through reasonable configuration of fuel reserves and supply methods, it ensures uninterrupted energy supply under prolonged emergency operation conditions, enabling the fire pump to continuously output the required water volume, providing a solid guarantee for on-site firefighting. The control system plays a crucial role in heavy-duty fire pump power systems. It typically integrates multiple operating modes and protection functions, effectively adjusting power output according to actual working conditions. Simultaneously, it monitors key operating parameters in real time, including speed, oil pressure, temperature, and operating status. In case of abnormalities, it can promptly issue alarms and take corresponding protective measures to prevent equipment from continuing to operate under abnormal conditions, thereby reducing the risk of failure. This type of power system also exhibits excellent starting performance, possessing rapid response capabilities. It can quickly commence operation upon receiving a fire start signal, providing sufficient power to the fire pump, especially in the initial stages of a fire, effectively shortening system response time and improving the overall emergency response efficiency of the fire protection system. To adapt to the application needs of different projects, heavy-duty fire pump power systems offer high flexibility in configuration. They can be rationally matched according to the fire pump’s flow rate, head, and system layout to ensure an optimal balance between power output and pump performance, thereby achieving both high-efficiency operation and energy-saving effects. In terms of manufacturing processes, this type of power system emphasizes detail and quality control. Key components undergo rigorous processing and testing, and the entire unit typically undergoes long-term load operation verification before leaving the factory to ensure reliable performance under actual emergency conditions. The equipment base and mounting structure generally adopt a reinforced design with good vibration resistance, effectively reducing the impact of vibration generated during operation on system stability, while also facilitating overall on-site installation and subsequent maintenance. Heavy-duty fire pump power systems demonstrate excellent environmental adaptability in practical applications. Whether in high-temperature, high-humidity, and dusty industrial environments, or in emergency situations where they are suddenly put into high-load operation after long periods of standby, they maintain stable and reliable performance, which is of great significance for ensuring fire safety in key locations. In summary, heavy-duty fire pump power systems, with their powerful power output, excellent continuous operation performance, comprehensive control and protection mechanisms, and high adaptability to complex working conditions, provide reliable support for long-term emergency operation. They are an indispensable and important component of modern high-standard fire protection systems. Their stability and durability demonstrated in actual firefighting operations provide a solid guarantee for the continuous operation of fire water supply systems and play a vital role in reducing fire risks and protecting the lives and property of people.