The Engineering Value of Split Case Pumps: Achieving Efficient and Low-Noise Fire Protection

Horizontal split case pumps offer high efficiency, low noise, and easy maintenance, making them ideal for firefighting water systems in high-rise buildings, municipal projects, and industrial facilities, ensuring reliable and energy-efficient performance.

With the acceleration of urbanization and the rising standards of public safety, the importance of reliable firefighting infrastructure has never been greater. At the heart of every firefighting water supply system lies the fire pump, whose efficiency and reliability determine how quickly and effectively fires can be controlled. Among the many types of fire pumps, the horizontal split case pump stands out for its superior design, operational stability, and exceptional efficiency. It is widely used in high-rise buildings, municipal water systems, industrial facilities, and infrastructure projects. This article delves into the technical design and practical benefits of horizontal split case pumps, particularly in achieving high efficiency and low noise performance for firefighting applications.

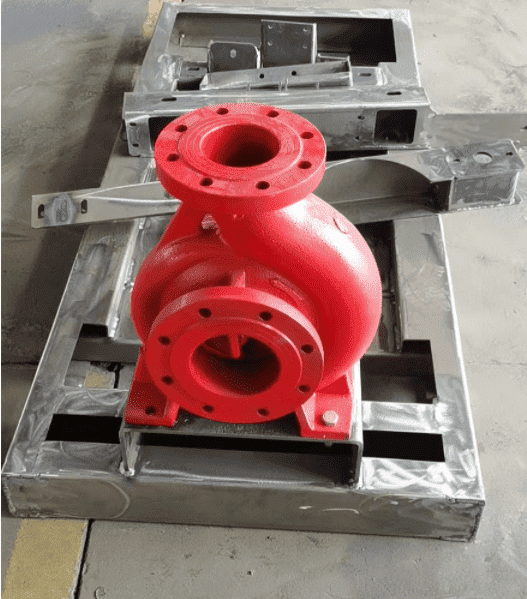

The most distinguishing feature of a horizontal split case pump is its split casing design—meaning the pump casing is divided horizontally along the centerline. This structural advantage allows for easy maintenance without removing the motor or pipeline connections. In fire protection scenarios, where the system must remain on standby 24/7, this feature significantly reduces downtime and ensures that emergency water delivery remains uninterrupted.

In terms of performance, horizontal split case pumps are designed for large flow and high head delivery, making them ideal for demanding water transport tasks. The internal flow channels are optimized using advanced hydraulic modeling, reducing turbulence and minimizing energy loss. The pump body is typically constructed from high-quality cast iron or stainless steel, ensuring strong resistance to corrosion and long-term durability. Some premium models also include double-suction impellers, which enhance hydraulic balance, reduce axial loads, and improve smooth operation.

Noise control is another strong suit of this pump type. Its balanced design, along with precisely machined bearing assemblies and dynamically balanced impellers, ensures quiet and vibration-free operation. This makes it highly suitable for noise-sensitive environments like hospitals, office towers, and underground spaces. In addition, the stable base frame and robust mounting help prevent resonance and mechanical vibration, further suppressing operating noise.

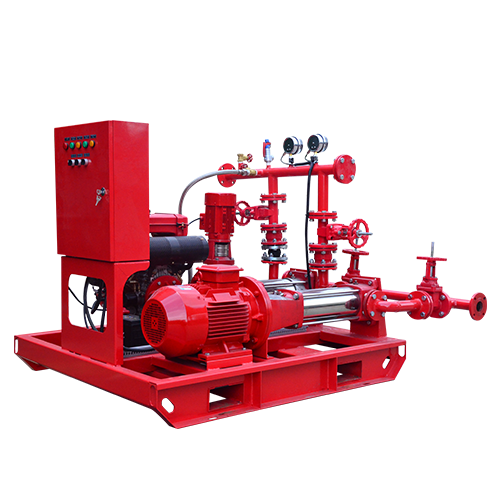

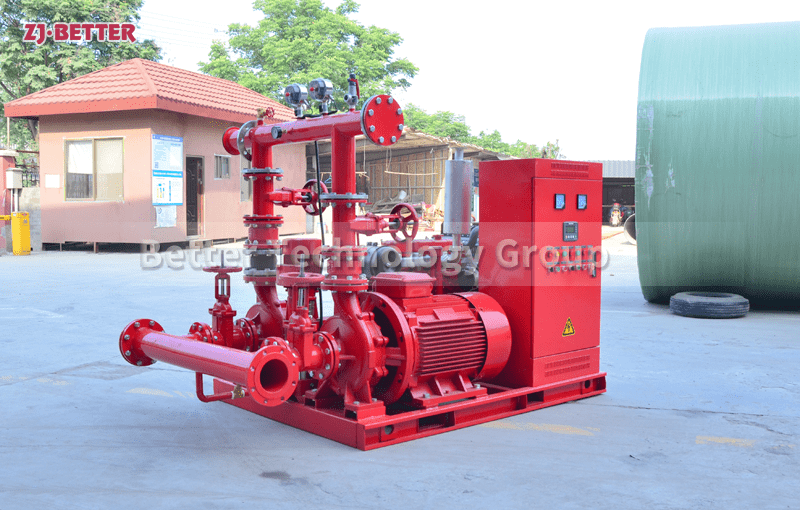

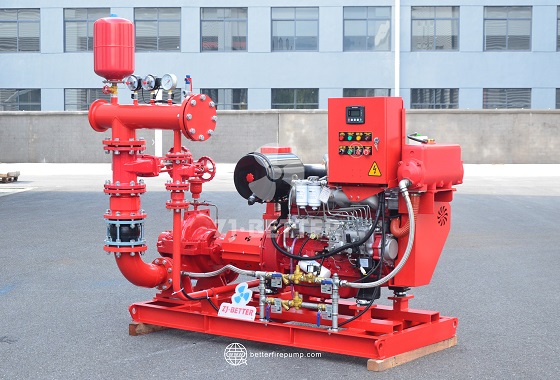

Horizontal split case pumps can be driven by electric motors or coupled with diesel engines for backup power configurations. In remote locations or critical infrastructure, where grid electricity may be unreliable, the diesel-driven option guarantees uninterrupted fire protection. This dual-power design greatly enhances system flexibility and resilience in emergencies.

To meet the increasing demand for intelligent fire safety systems, many horizontal split case pump models are now integrated with smart monitoring capabilities. These include real-time data collection of parameters such as flow rate, pressure, temperature, and current. Alarms can be triggered automatically in case of anomalies, ensuring quick response and system safety. The integration of digital control significantly improves operational management and enhances reliability.

From a safety standpoint, horizontal split case pumps are built with advanced sealing systems, usually including mechanical and packing seals to prevent leaks. The bearing housing is engineered for optimal heat dissipation, minimizing the risk of thermal failure during prolonged operation. These pumps are also certified under strict national and international safety standards.

Their modular structure allows for flexible installation, whether above ground or integrated with pressure tanks and storage reservoirs. This adaptability makes them compatible with various engineering setups and significantly simplifies onsite assembly, reducing time and cost.

Given their performance and design strengths, horizontal split case pumps are not only limited to fire safety. They are also extensively used in municipal waterworks, industrial circulation, HVAC cooling, and more, representing a cutting-edge solution with cross-industry applicability. They embody the future of pump technology: efficient, durable, and smart.

In conclusion, the horizontal split case pump stands as a paragon of engineering excellence in the firefighting field. Its efficient hydraulic performance, low-noise operation, ease of maintenance, and smart system compatibility make it a critical component in modern fire protection systems. As cities become smarter and more demanding in terms of safety and efficiency, this pump will continue to play a pivotal role in securing lives and infrastructure.