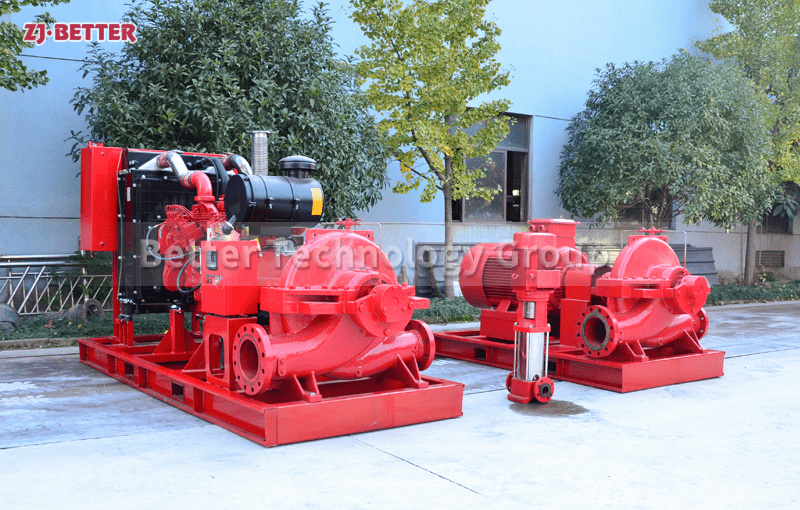

Fully Enclosed Fire Pump Equipment Solution Enhancing System Reliability

The fully enclosed fire pump equipment solution adopts an integrated enclosed structure design, which effectively protects against the effects of wind, rain, dust and complex environments. It integrates a high-efficiency fire pump, a stable power system and intelligent control device, supports rapid installation and continuous operation, and significantly improves the reliability, safety and long-term operational stability of the fire water supply system.

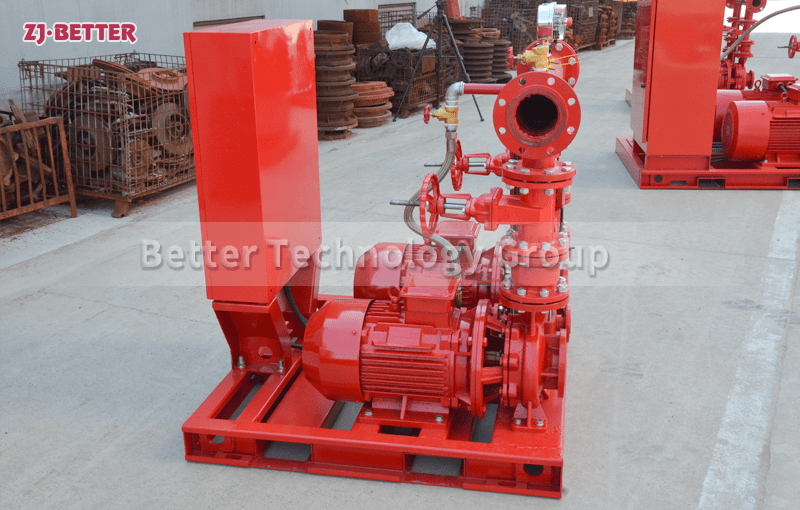

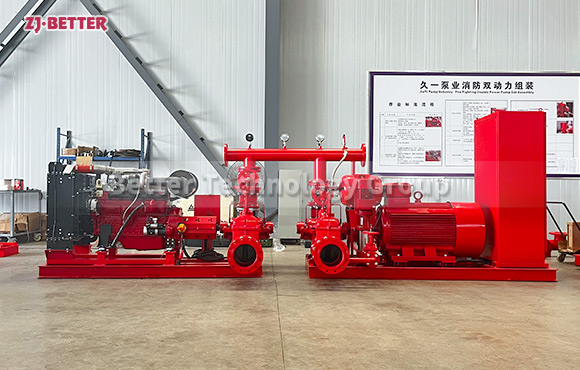

Fully Enclosed Fire Pump Equipment Solution | Enhancing System Reliability: This comprehensive equipment solution is developed to meet the high reliability and stability requirements of modern fire protection systems. Its core advantage lies in its fully enclosed structural design and highly integrated configuration, providing continuous, safe, and stable operating conditions for fire pumps in various complex environments, thereby significantly improving the availability and reliability of the entire fire water supply system at critical moments. This type of fully enclosed fire pump equipment typically integrates the fire pump set, power system, control system, piping components, and auxiliary devices within a sealed protective enclosure, effectively isolating the equipment from adverse environmental influences. It is particularly suitable for outdoor installations, projects without independent pump rooms, and applications requiring high levels of equipment protection. The fully enclosed structure fully considers factors such as rainproofing, dustproofing, wind and sand protection, and high-temperature resistance during the design phase. Through a reasonable enclosure structure and sealing design, it ensures stable operation of the equipment even in harsh climates or complex industrial environments, avoiding performance degradation or increased failure risk due to environmental corrosion. As the core component of the entire system, the fire pump’s hydraulic performance has been meticulously optimized, boasting high efficiency, large flow rate, and stable head output. It can rapidly establish system pressure during a fire, providing a continuous and reliable fire water source for indoor fire hydrant systems, automatic sprinkler systems, and outdoor fire hydrant networks. Even under high-load conditions with multiple points using water simultaneously, it can maintain a stable water supply, effectively improving fire extinguishing efficiency. The fully enclosed fire pump equipment solution emphasizes matching and stability in its power system configuration. Different types of power units can be rationally configured according to project requirements, ensuring the fire pump maintains stable output during startup and continuous operation, reducing the impact of power fluctuations on system operation. This is particularly crucial for rapid response in the early stages of a fire and continuous water supply during prolonged firefighting. The control system is a vital guarantee for the high reliability of this solution. It typically employs a combination of automatic and manual control, automatically starting and stopping based on changes in pipeline pressure or external fire signals. It also supports manual intervention in special circumstances, ensuring the fire pump can be quickly deployed under any conditions. The control system integrates multiple monitoring and protection functions, enabling real-time monitoring of operational status and timely alarm prompts in case of anomalies. This helps managers quickly locate problems and take appropriate measures, thereby reducing the risk of system failure. The fully enclosed design not only enhances equipment safety but also improves the operating environment. Through a rational sound insulation and vibration reduction structure design, it effectively reduces noise and vibration generated during equipment operation, making it more suitable for environments with high environmental requirements, such as commercial buildings, data centers, public facilities, and urban complexes. The internal layout of the enclosure is scientifically planned, with functional modules arranged in an orderly manner. This ensures adequate heat dissipation during operation while providing ample space for daily inspection and maintenance, maintaining high integration while ensuring good maintainability. The fully enclosed fire pump equipment solution also offers significant advantages in installation and deployment. Its modular design greatly reduces on-site construction and commissioning work; only foundation positioning and piping and electrical connections are required for immediate use, significantly shortening the project construction cycle. This is particularly suitable for projects with tight schedules or limited construction conditions. The equipment base typically employs a high-strength structural design, possessing excellent load-bearing capacity and vibration resistance. It effectively absorbs mechanical vibrations generated during equipment operation, further enhancing the overall system’s operational stability. Designed for long-term standby use, this type of fully enclosed fire pump equipment emphasizes durability and reliability in material selection and manufacturing processes. Key components exhibit excellent wear and corrosion resistance, enabling rapid recovery to optimal operating conditions after prolonged static standby, meeting the basic requirement of readily available fire protection systems. For management, the fully enclosed fire pump equipment solution not only provides reliable protection during fires but also demonstrates excellent economic efficiency in daily operation. By reducing the impact of environmental factors on the equipment, it decreases maintenance frequency and the probability of failure, effectively reducing overall operation and maintenance costs. In summary, the fully enclosed fire pump equipment solution, through its multiple advantages of structural protection, performance optimization, and system integration, provides a more reliable, safe, and efficient operating foundation for fire water supply systems. Its stability, adaptability, and rapid response capabilities demonstrated in practical applications build a solid fire safety barrier for various critical locations, making it an ideal choice for improving system reliability in modern fire protection engineering.