Optimized Energy Efficiency in Fire Systems with Electric Pump Solutions

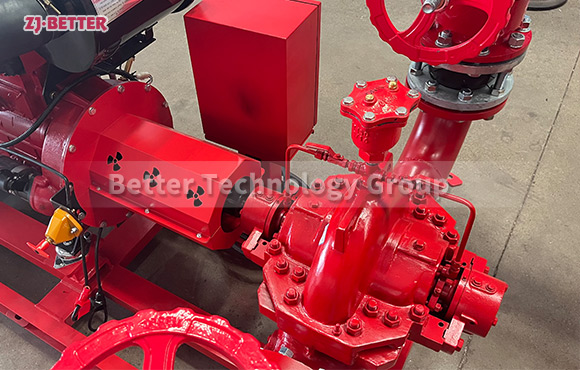

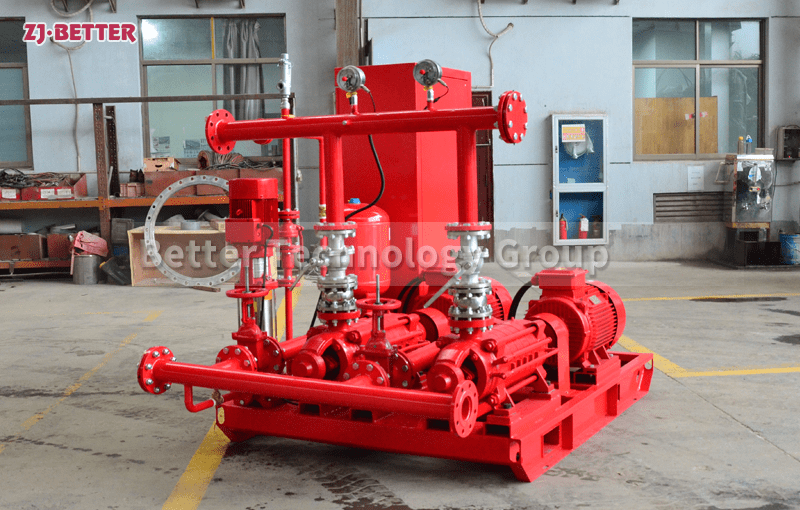

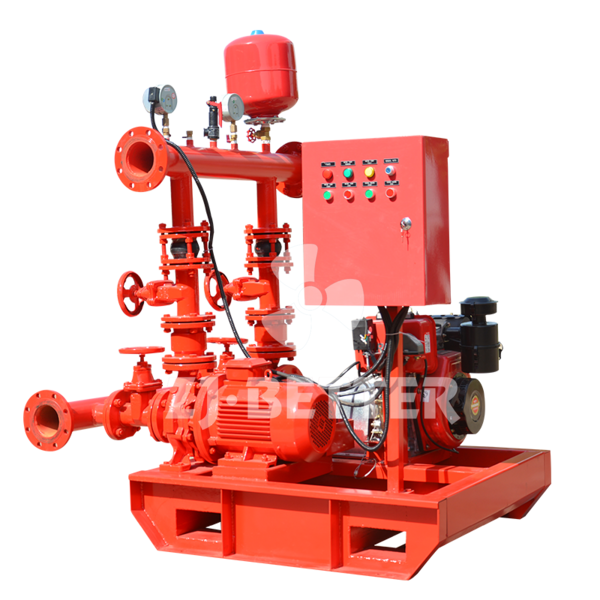

Electric fire pumps are renowned for their high efficiency, energy saving, stable operation, and intelligent control, making them an ideal solution for optimizing the energy efficiency of fire protection systems. They feature automatic start/stop, variable frequency speed control, high head and large flow rate, low noise, and multiple safety protection functions. Suitable for high-rise buildings, industrial plants, and commercial complexes, they ensure a continuous and stable emergency water supply, providing highly reliable and high-performance safety assurance for modern fire protection systems.

In modern building fire protection systems, electric fire pumps, with their significant advantages such as high efficiency, energy saving, stable operation, and rapid response, have become core equipment for ensuring continuous pressure and emergency water supply in fire water supply systems. Electric pump solutions that optimize the energy efficiency of fire protection systems not only reflect advancements in fire protection technology but also embody a dual improvement in energy utilization efficiency and safety performance. These pump sets use electric motors as the main power source and achieve automatic start-up, constant pressure operation, and multi-mode switching through advanced control systems, thereby ensuring uninterrupted water supply in emergencies such as fires. The entire system typically consists of a main pump, a pressure-stabilizing pump, a control cabinet, a pressure tank, and a piping system. These components work together to achieve precise control, energy-saving operation, and long-term reliability. One of the most prominent advantages of electric fire pumps is their comprehensive optimization of energy efficiency. Compared to traditional pump sets, they achieve a significant improvement in operating efficiency. The electric drive structure makes energy conversion more direct, reduces mechanical losses, and allows for more precise energy consumption control. The electric motor has a soft-start function, which effectively reduces the impact of starting current on the power grid and extends the life of the pump body and motor. With an intelligent variable frequency control system, the pump’s operating speed can be automatically adjusted according to actual pressure requirements, thus avoiding ineffective high-power output and maximizing energy savings while ensuring stable water supply. Furthermore, the optimized hydraulic design and high-efficiency impeller structure ensure smoother fluid flow inside the pump body, significantly reducing hydraulic losses and improving overall efficiency by more than 15% compared to traditional fire pump systems. In terms of performance, the electric fire pump possesses comprehensive characteristics of high head, large flow rate, and stable output, maintaining strong water supply capacity in various complex environments. Its wide operating pressure range and uniform flow output can cover different types of fire protection needs, including high-rise buildings, industrial plants, warehousing facilities, commercial complexes, and infrastructure. The pump body is made of high-quality corrosion-resistant materials, capable of withstanding long-term high-pressure operation and frequent start-stop conditions, ensuring the system maintains good operating performance even in high-temperature, high-humidity, and dusty environments. To ensure rapid system response, the electric fire pump’s control system adopts a fully automatic logic control design, enabling automatic start-stop via pressure signals or remote commands, and supporting manual operation mode switching, ensuring system flexibility and safety in different application scenarios. The control cabinet features a built-in intelligent monitoring module that can monitor the pump’s operating current, voltage, pressure, and temperature data in real time, and has abnormal alarm and self-protection functions. When the system detects overvoltage, undervoltage, overload, or dry operation risks, it will immediately issue an alarm or automatically shut down to prevent equipment damage and ensure safe operation. Simultaneously, the system can achieve online management and data recording through a remote monitoring platform, providing a reliable basis for later maintenance and energy consumption analysis. The electric fire pump’s structural design emphasizes compactness and modularity, making installation and maintenance more convenient. The pump unit adopts an integrated base structure, allowing direct installation on the equipment room floor or foundation platform without complex piping modifications, saving construction time and costs. The piping interface design conforms to international standards, ensuring compatibility with various fire protection systems and strong adaptability. In terms of maintenance, the main vulnerable components of the electric pump are easy to replace, and daily maintenance is simple, requiring only periodic checks of the shaft seals, couplings, and bearing lubrication, greatly reducing operating and maintenance costs. The electric fire pump’s energy-saving performance is particularly outstanding. Through intelligent variable frequency speed control technology, the system can maintain pipeline pressure at low speed in non-fire alarm states. When a pressure drop or fire alarm signal is detected, it immediately switches to high-power mode to supply water at full speed, avoiding energy waste caused by long-term high-load operation of traditional pump sets. According to test data, electric fire pump sets using variable frequency control can save approximately 30% to 45% of electricity compared to constant-speed pumps, significantly reducing operating costs while meeting modern energy-saving and environmental protection standards. In addition, the noise control and vibration suppression technology of electric fire pumps has also been optimized. Through dynamic balanced impeller design and high-precision coupling structure, the pump set noise is significantly reduced during operation, and the overall vibration amplitude is controlled within the safe standard range, providing a quieter working environment for the machine room. This feature not only improves the comfort of equipment use but also extends the service life of mechanical components. Safety is another core consideration in the design of electric fire pumps. The system adopts multiple electrical protection mechanisms, including short-circuit protection, overload protection, phase sequence protection, leakage detection, and automatic reset functions, ensuring that the equipment can be safely shut down or restarted under various electrical abnormalities. Meanwhile, to prevent the impact of unexpected power outages on water supply, the pump set can also be linked with the backup power system or diesel drive system to achieve seamless switching, ensuring the fire protection system can continue to operate under extreme conditions. Electric fire pumps not only possess high performance and high reliability but have also achieved significant breakthroughs in intelligent technology. Modern electric pump systems support IoT monitoring, remote diagnostics, and automatic data uploading. Managers can monitor the pump set’s operating status in real time via computer or mobile terminal, perform parameter settings, fault warnings, and historical data queries, achieving truly intelligent fire management. This data-driven management model significantly improves the controllability and response speed of the fire protection system and provides a solid technical foundation for future smart city construction. In terms of materials and manufacturing processes, every component of the electric fire pump undergoes rigorous testing and precision machining to ensure that structural strength and sealing performance meet international standards. The pump casing is made of high-strength cast iron or stainless steel, and the inner surface is treated with an anti-corrosion coating to effectively prevent wear caused by long-term water flow. The shaft seal uses a high-temperature resistant mechanical seal to prevent leakage and extend service life. The motor uses a high-efficiency energy-saving motor with excellent starting performance and thermal protection devices, allowing for continuous long-term operation without overheating. Overall, electric pump solutions that optimize the energy efficiency of fire protection systems represent the high standard of current fire water supply technology. They not only achieve precise regulation of pressure and flow through intelligent control, but also reach industry-leading levels in safety, reliability, and energy efficiency. Whether in large public buildings, industrial zones, airports, docks, or commercial complexes and residential communities, electric fire pumps provide stable and efficient water supply, making them an indispensable piece of equipment in modern fire protection systems. Their application not only improves the overall efficiency of fire protection systems but also contributes to energy conservation, emission reduction, and sustainable development goals, becoming an irreplaceable key component of modern urban safety protection systems.