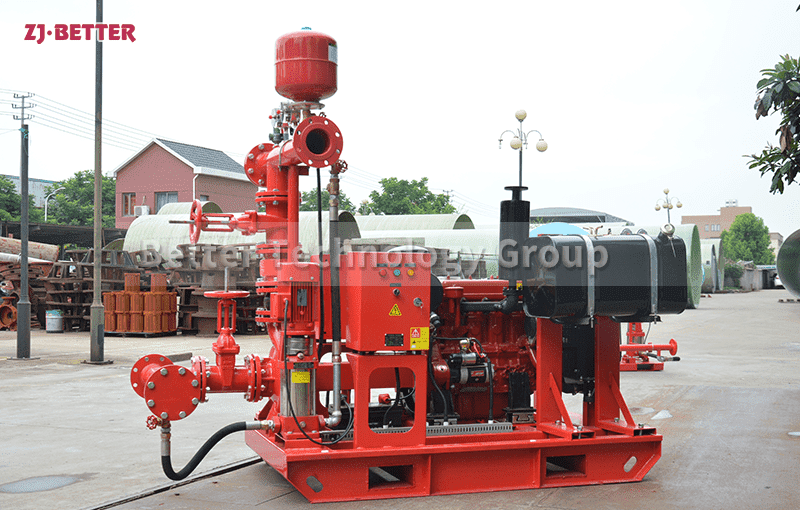

Mainly used for fire fighting system pipeline pressurized water supply diesel engine fire pump

Diesel engine fire pumps can be divided into self-priming, centrifugal and double-suction types. Self-priming pumps are widely used in urban flood control and emergency rescue. Centrifugal pumps are divided into single-stage centrifugal pumps and multistage centrifugal pumps.

Diesel engine fire pumps are mainly used for pressurized water delivery in fire protection system pipelines. It can also be applied to industrial and urban water supply and drainage, high-rise building pressurized water supply, long-distance water supply, heating, bathroom, boiler cold and warm water circulation pressurized air conditioning refrigeration system water supply and equipment matching and other occasions. The part of the pump body and the pump cover of the diesel engine fire pump is split from the back of the impeller, which is the so-called rear door structure. The advantage is that the maintenance is convenient. During maintenance, the pump body, the suction pipeline, the discharge pipeline and the motor are not moved, and the rotor part can be withdrawn for maintenance only by removing (lengthening) the intermediate connecting piece of the coupling. The casing of the diesel engine fire pump constitutes the working chamber of the pump. The impeller, shaft and rolling bearing are the rotors of the pump. The suspension bearing part supports the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump. In order to balance the axial force of the diesel engine fire pump, most pumps are provided with sealing rings at the front and rear of the impeller, and a balance hole is provided on the back cover of the impeller. Due to the small axial force of some pumps, there is no seal on the back of the impeller. Ring and balance hole.