Ultimate Fire Protection During Power Outages: Independently Operated Diesel Fire Pump Systems

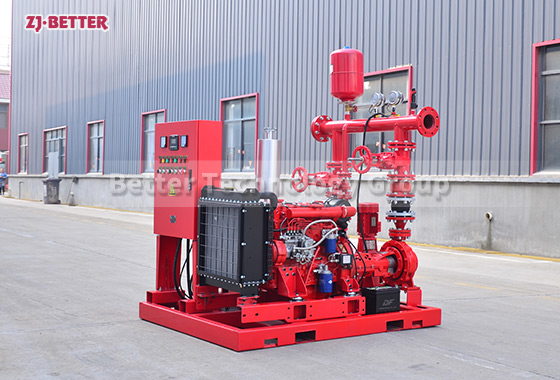

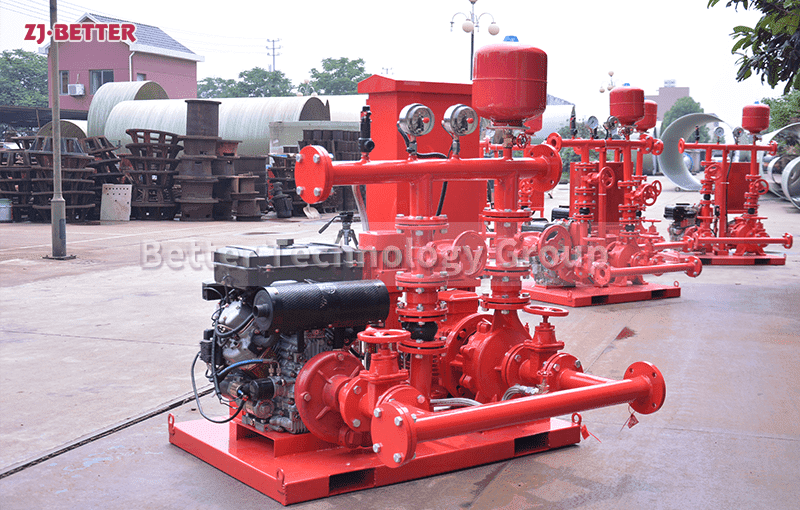

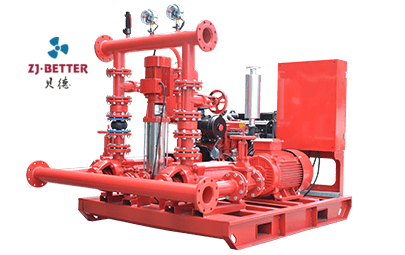

The independently operated diesel fire pump provides reliable firefighting water supply in power-outage environments, featuring robust power output, automatic start-up control, high energy efficiency, and exceptional durability. Suitable for fire protection systems in high-rise buildings, industrial facilities, and remote areas, it ensures continuous and stable water pressure supply during fire emergencies.

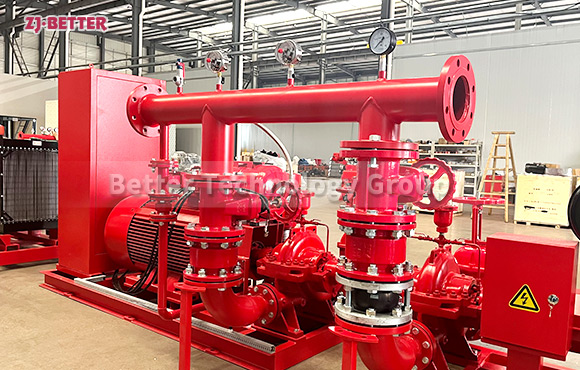

In modern fire safety systems, stable and reliable firefighting water supply equipment is crucial for ensuring efficient fire response and personnel safety. In scenarios such as power outages, remote locations, or special environments, diesel fire pump systems capable of independent operation become the core equipment for maintaining continuous firefighting water supply. Powered by diesel engines and independent of external grid supply, these systems can rapidly activate even under extreme conditions. They deliver ample and stable high-pressure water flow to firefighting pipelines, providing robust support for initial fire containment and subsequent suppression. Diesel fire pump systems are widely deployed in industrial zones, warehousing and logistics centers, petrochemical complexes, high-rise buildings, ports, and power facilities. They demonstrate irreplaceable advantages, particularly in critical areas demanding uninterrupted firefighting water supply. The greatest advantage of diesel fire pumps lies in their “stand-alone operation” capability. When electric pumps fail due to power outages, the diesel system automatically takes over water supply duties. Its control system continuously monitors water pressure changes and automatically starts the engine, rapidly establishing rated pressure to ensure uninterrupted fire suppression. This feature is particularly vital in areas prone to frequent power outages or unstable electricity supply, effectively safeguarding continuous fire safety. Furthermore, diesel fire pump systems utilize high-performance diesel engines that deliver robust power output and high torque, maintaining stable performance under heavy loads and prolonged continuous operation. The engine and pump are connected via high-precision couplings, ensuring efficient power transmission with minimal vibration and low energy consumption. Combined with an optimized centrifugal or multistage pump design, the system delivers high flow rates alongside elevated head capabilities, meeting the demands of large-scale buildings, long-distance water transport, and high-pressure sprinkler systems. Structurally, the diesel fire pump system features a compact layout with a small footprint, facilitating installation and maintenance. The base employs a thickened carbon steel welded structure, offering high rigidity and vibration resistance to minimize mechanical vibrations during engine operation and extend equipment lifespan. The system incorporates advanced water-cooled or air-cooled heat dissipation systems, allowing selection of the optimal cooling method based on environmental conditions to ensure stable, long-term engine operation without overheating. The control system features an intelligent control cabinet with three operating modes: fully automatic, manual, and remote. In automatic mode, the control system continuously monitors pipeline pressure. When pressure falls below the set value, it automatically issues a start command, rapidly igniting the diesel engine and activating the pump set. When water pressure returns to normal range, the system automatically shuts down. The entire process requires no manual intervention, achieving true unattended automatic operation. The control system also incorporates multiple safety protections, including low oil pressure alarm, high water temperature protection, start failure alarm, overspeed protection, and low oil level alarm, ensuring safe and reliable operation under all conditions. The fuel system design represents another technical highlight of diesel fire pumps. Utilizing high-efficiency injection fuel supply technology and low-consumption diesel engines, the system achieves complete combustion and stable power output while significantly reducing operating costs. An independent fuel tank ensures continuous operation exceeding 8 hours, meeting the prolonged operational demands of emergency fire situations. Some systems also support dual-tank switching design, enabling fuel replenishment without interrupting operation, greatly enhancing sustained working capability. Regarding starting methods, diesel fire pump systems typically employ electric or pneumatic starting. Electric starting systems feature battery packs and intelligent charging modules, maintaining sufficient power during extended standby periods to ensure rapid engine response upon command. Pneumatic starting systems are suited for low-temperature or power-deprived environments, utilizing high-pressure gas to drive engine ignition, guaranteeing reliable operation even under extreme climatic conditions. The pump body is constructed from premium cast iron or stainless steel. Its internal hydraulic design undergoes CFD optimization, featuring smooth flow paths, high efficiency, and strong cavitation resistance, effectively enhancing operational efficiency and service life. The pump shaft undergoes high-precision machining and dynamic balancing, ensuring stable rotation, low noise, and extended maintenance intervals. The mechanical seal system employs high-temperature and wear-resistant materials, maintaining excellent sealing performance under high pressure and temperature to prevent leakage. The entire system undergoes rigorous factory testing, including performance evaluations, pressure endurance tests, and start-up response assessments, ensuring each unit meets national and international fire safety standards upon delivery. In practical applications, diesel fire pump systems are often integrated with electric fire pumps and pressure-stabilizing pumps to form complete fire pump sets, enabling multi-stage coordination. When electric pumps cease operation due to power failure, diesel pumps automatically activate to maintain water supply. Pressure-stabilizing pumps sustain pipeline pressure during normal operation, ensuring the entire system remains in optimal working condition. This configuration not only enhances fire protection system reliability but also optimizes energy efficiency. Regarding maintenance and operation, the diesel fire pump system prioritizes user-friendly design and serviceability. All critical components are easily accessible for disassembly and inspection, while the control panel features intuitive operation logic, allowing users to effortlessly perform routine checks and maintenance. The system incorporates multiple monitoring interfaces for integration with Building Automation Systems (BAS) or fire monitoring systems, enabling remote monitoring and status feedback for streamlined management and dispatch. This equipment also demonstrates exceptional environmental adaptability, operating reliably in both scorching tropical regions and frigid high-altitude environments. Through the configuration of preheating systems, intake air heating devices, or low-temperature start-up aids, the diesel engine can still start smoothly under low-temperature conditions, ensuring rapid response in emergencies. Additionally, the system features a high protection rating, with specially designed electrical components, anti-vibration bases, and dust covers suitable for outdoor or harsh industrial environments. In terms of energy efficiency and environmental protection, the modern diesel fire pump system adopts low-emission technology and high-efficiency combustion systems, significantly reducing exhaust emissions and noise pollution, meeting international environmental standards. Certain models incorporate exhaust mufflers and vibration damping systems, operating below national noise standards. This makes them suitable for noise-sensitive areas such as hospitals, residential communities, or commercial complexes. Overall, the independently operated diesel fire pump system stands as an ideal solution for firefighting water supply during power outages, offering robust power output, exceptional reliability, intelligent control systems, and outstanding environmental adaptability. Whether in urban buildings or remote facilities, this system delivers stable firefighting water supply during critical moments, establishing a robust defense for safeguarding lives and property. It serves not only as a vital component of fire protection systems but also as indispensable, high-efficiency power equipment within modern safety protection frameworks.