Independent Diesel Fire Pump System: The Perfect Emergency Solution During Power Outages

The standalone diesel fire pump system offers powerful power and exceptional reliability, automatically starting and maintaining continuous water supply even during power outages or harsh environments. Powered by a highly efficient diesel engine, this system features an intelligent control system and multiple safety features. Widely used in industrial plants, high-rise buildings, oil depots, and ports, it provides a stable, high-pressure water source for firefighting systems, ensuring uninterrupted emergency water supply. It’s an ideal firefighting solution for power outages.

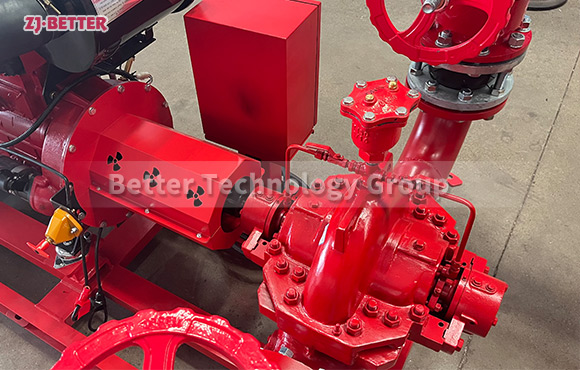

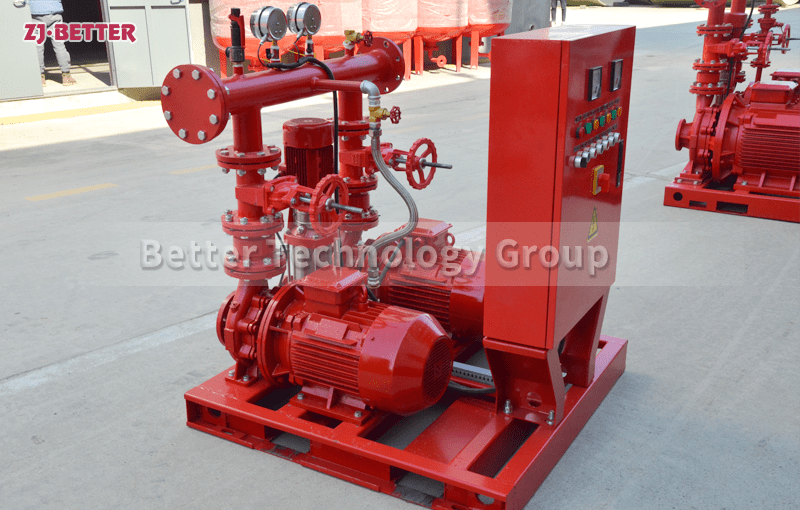

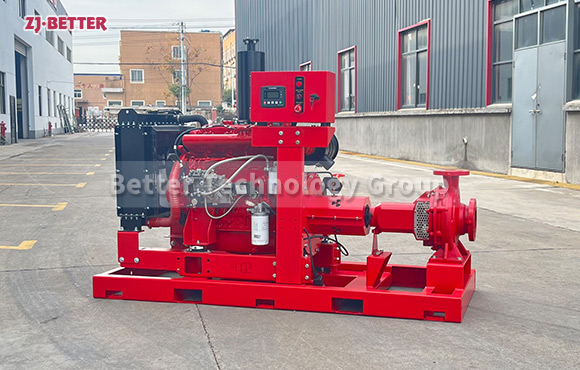

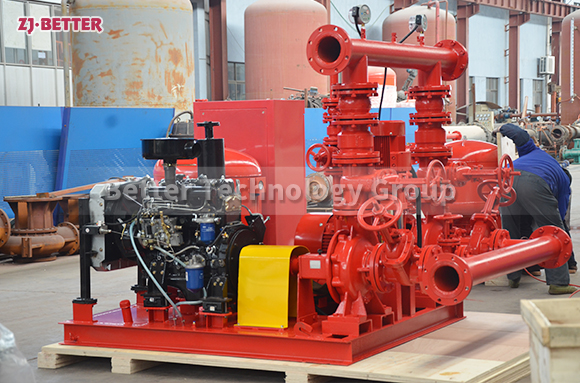

The standalone diesel fire pump system is a highly reliable fire water supply system designed to withstand power outages and extreme environments. Powered by a diesel engine, it operates independently of the external grid and continuously provides high-pressure fire water during fires or power outages, ensuring rapid start-up and continuous operation of the firefighting system. Widely used in industrial plants, high-rise buildings, storage and logistics bases, petrochemical facilities, ports and terminals, power stations, and remote areas without reliable power supply, the system is an indispensable emergency water supply component in modern firefighting systems. Designed with efficiency, stability, intelligence, and safety in mind, the diesel fire pump system utilizes internationally standardized mechanical structure and control logic to ensure reliable operation in the most demanding environments. The system consists of a diesel engine, centrifugal pump, coupling, base, control cabinet, fuel system, cooling system, exhaust system, and battery starting system. The diesel engine directly drives the pump through a flexible coupling, resulting in high transmission efficiency, low mechanical loss, and rapid start-up and strong output. The main pump utilizes a high-performance hydraulic model, offering high head and high flow rates, meeting the water supply needs of various fire sprinkler, fire hydrant, and foam fire extinguishing systems. Compared to traditional electric pumps, the greatest advantage of diesel fire pumps lies in their independence and reliability. In the event of a power system failure, fire damage to the distribution cabinet, or a power outage, the system can continue to operate independently using its own diesel engine, unaffected by any external power supply conditions. The diesel engine utilizes an electronically controlled fuel injection system, ensuring efficient combustion, stable power output, low fuel consumption, and compliant emissions. The fuel tank capacity can be customized to meet specific requirements, ensuring continuous operation for several hours or more, meeting the long-term water supply requirements of large and medium-sized buildings or industrial projects. The starting system utilizes a battery-powered electric starter, supplemented by a manual emergency starter, ensuring smooth starting even in cold, humid, and other harsh conditions. The fire pump system utilizes a fully automatic intelligent control cabinet, enabling one-touch start and stop, as well as full monitoring. The control system automatically monitors pipe pressure and, when pressure falls below a set value, automatically issues a start command, rapidly activating the diesel engine and commencing water supply. Once pressure returns to a set upper limit, the system automatically shuts down and enters standby mode, enabling fully automated, unattended operation. The control system can also receive remote pump start commands from the fire control center or fire alarm signals, activating the main pump the instant the alarm is triggered, ensuring that firefighting water reaches the fire scene immediately. The entire system’s response time typically exceeds 15 seconds, significantly improving emergency response speed. In terms of performance, the diesel fire pump system offers excellent hydraulic efficiency and operational stability. The pump body is constructed of high-quality cast iron or stainless steel, offering high strength, wear resistance, and corrosion resistance, making it suitable for media such as fresh water, mildly corrosive liquids, and foam mixtures. The pump shaft is precision machined and dynamically balanced for smooth operation with low noise and vibration. The shaft seal utilizes a dual mechanical seal or packing seal structure to ensure long-term, leak-proof operation. The diesel engine and pump base utilize a single-piece welded frame with shock-absorbing pads at the bottom to effectively reduce vibration transmission during operation, thereby enhancing operational stability and equipment life. System cooling options include closed-loop water cooling or air cooling, depending on the power configuration. The water cooling system circulates coolant to reduce diesel engine temperature, ensuring unimpeded performance even during prolonged, high-load operation. The exhaust system utilizes high-temperature-resistant silencer piping, ensuring operating noise levels meet industrial standards and can be safely used in indoor or semi-enclosed environments. Regarding safety, the diesel fire pump system is equipped with comprehensive protection and alarm devices. The control cabinet incorporates multiple safety features, including low oil pressure alarms, overspeed alarms, high water temperature alarms, oil temperature alarms, low battery voltage alarms, and automatic shutdown protection. If the system detects any abnormality, it immediately issues audible and visual alarm signals and automatically shuts down or switches the system according to pre-set logic to prevent equipment damage. A check valve and a pressure relief valve are installed at the pump outlet to prevent backflow and water hammer, protecting the pipe network. The system also features an automatic preheating function, ensuring normal startup and operation even in cold regions or winter temperatures. This diesel fire pump system was designed with energy conservation and ease of maintenance in mind. The diesel engine utilizes an advanced fuel control system to improve combustion efficiency, reduce emissions and fuel consumption, and thus lower operating costs. The system’s compact design and small footprint facilitate transportation and installation. Customizable base reinforcement, pipe connections, and special structural configurations, such as rainproof, dustproof, and explosion-proof, can be tailored to the user’s site requirements. The user-friendly control panel features an LCD display and a multilingual interface, displaying real-time operating parameters such as oil pressure, water temperature, speed, water pressure, and flow rate, allowing operators to easily understand operating status and make maintenance decisions. For equipment maintenance, the system provides ample access for easy replacement of filters, lubricants, and consumable parts, significantly reducing maintenance time and costs. The standalone diesel fire pump system is widely applicable in locations without a stable power supply or where power safety requirements are high. In industrial projects, it can serve as a primary or backup pump system, ensuring uninterrupted water supply during fire emergencies. In high-rise buildings and residential areas, it can serve as a secondary power source for firefighting water supply, complementing electric pumps. In specialized areas such as ports, docks, airports, oil depots, and mines, the system’s high flow and high pressure output capabilities meet the needs of large-scale water spraying or long-distance water delivery. For temporary construction sites, field operations, or emergency rescue operations, it can be deployed independently and quickly put into operation, becoming a portable emergency water supply platform. Reliability and durability are key to the system’s market acceptance. All components undergo rigorous factory testing, including pressure testing, leak testing, startup testing, and 24-hour continuous operation testing, to ensure that each unit exhibits excellent performance and stability before commissioning. The equipment complies with international fire protection standards such as NFPA20, ISO, and EN12845, enabling seamless integration with various fire protection systems. An optional remote monitoring module allows users to view real-time device operating status, alarm information, and historical records via the network, enabling remote management and troubleshooting, thus enhancing the system’s intelligence. In summary, the standalone diesel fire pump system, with its powerful power output, excellent self-starting capability, intelligent control technology, and comprehensive safety protection features, has become an irreplaceable core component in modern fire protection systems. It can operate reliably during power outages and harsh environments, providing a continuous and stable fire water supply for buildings, industry, energy, and public facilities. This system not only embodies the perfect combination of mechanical reliability and intelligent control, but also provides the strongest support for emergency response, such as fires, and is a key element in ensuring life and property safety.