Better Specializes in Manufacturing DJ Fire Pump Products

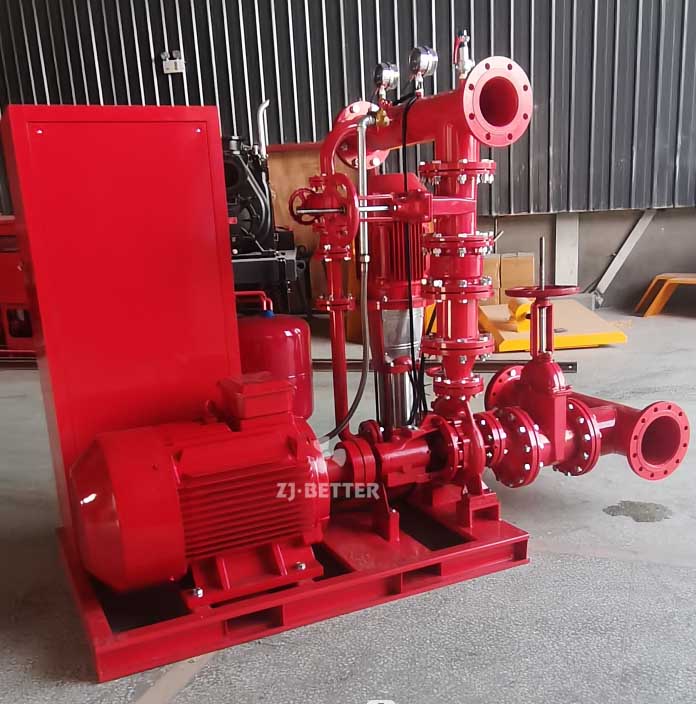

Fire pump components:

1. Diesel pump: the flow rate is the same as that of the electric pump. It connects pump sets with highly elastic couplings or universal joints.

2. Pipeline supplementary pressure pump: vertical, small flow, higher lift than electric or diesel pumps.

3. Control panel: Automatically control the water pump with overload and overcurrent protection.

4. Accessories: suction pipe, discharge pipe with flange, battery, gate valve, check valve, flexible expansion joint, pressure switch, pressure gauge, base, etc.

There are different types of fire pumps, which are also to meet the needs of different places. Fire pumps have different structural forms, so that suitable structures can be found in different places, thus meeting the needs of different users. It can be well applied in public places or mobile places.

The fire pump is a kind of equipment successfully developed using advanced technology and polymer materials, and also uses a lot of high-tech means, so it has many characteristics such as high efficiency and cleanliness, good safety sealing, corrosion resistance, etc. All these features ensure the service life of the product, and can also better help solve unexpected problems.

The fire pump is a device used to supplement water, foam or pressure products, so as to achieve the purpose of extinguishing fire, so it can ensure the supply of a large amount of fire extinguishing materials when a fire occurs, so as to achieve the purpose of extinguishing fire, so that it can be Help reduce economic losses.