The Core Equipment for Fire Safety in Critical Facilities – Diesel Engine Fire Pump Unit Explained

Diesel engine fire pump units offer autonomous startup, powerful water delivery, and excellent adaptability, making them essential fire protection equipment for critical facilities such as petrochemical plants, airports, and data centers, meeting modern intelligent and high-reliability safety standards.

In modern architectural and industrial environments, the independence and reliability of fire protection systems have become crucial indicators of safety standards. Especially in areas with unstable power supply or high outage risks—such as petrochemical plants, logistics warehouses, airports, data centers, large commercial complexes, underground facilities, and off-grid regions—ensuring uninterrupted firewater supply during emergencies is a primary challenge. The diesel engine-driven fire pump unit has emerged as the key solution to this issue, thanks to its robust power source, stable performance, and excellent adaptability.

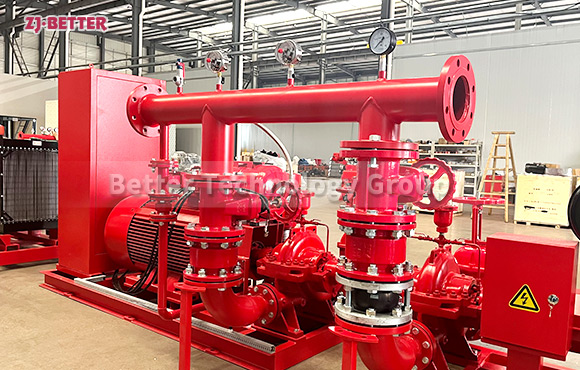

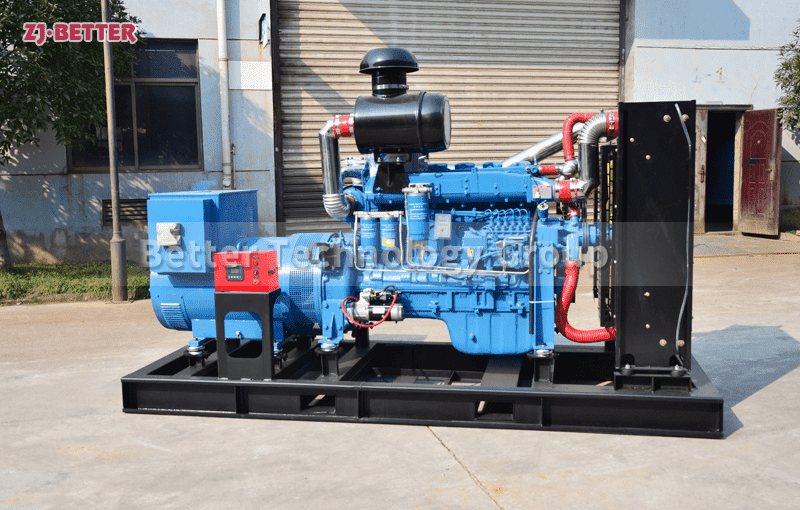

A diesel fire pump unit consists of a diesel engine, a high-efficiency coupling, a dedicated fire pump, an intelligent control system, and a fuel supply module. It can operate independently without any reliance on external power. The system is equipped with an automatic control cabinet and a remote monitoring module that supports automated start/stop, pump switching, and data communication with the central fire control system, enabling remote activation and real-time status tracking.

Its core power component—the diesel engine—is selected from globally recognized brands or compliant with national emission standards and features high torque output, fuel efficiency, fast ignition, and stable operation. The paired centrifugal fire pump adopts a horizontal single-stage or multistage structure, capable of delivering flow rates from 50 m³/h up to 1000 m³/h and heads up to 180 meters, meeting the hydraulic demands of complex firefighting designs.

From a structural and material standpoint, the base frame is made from high-strength welded steel or cast steel, offering excellent rigidity and anti-vibration performance. Pump bodies and wetted parts are available in cast iron, stainless steel, or ductile iron according to medium requirements and are equipped with mechanical seals to prevent leakage and wear, thereby extending operational life. For enhanced system performance, the unit may also include features such as automatic fuel refill, water cooling systems, exhaust silencers, vibration isolators, and fuel storage tanks, ensuring reliable operation even in extreme environments involving heat, humidity, or dust.

Compared to electric fire pumps, diesel fire pump units offer a significant advantage—their “off-grid autonomous operation” capability. In the event of a total power failure, they can still function via their self-contained energy system, serving as a true “secondary lifeline.” Their rapid response, environmental adaptability, and no-need-for-manual-intervention characteristics make them ideal for emergency response systems and first-line firewater strategies.

Certified by national fire protection authorities and ISO standards, diesel fire pump units can be customized based on project-specific needs, including control logic, piping layout, auto-detection modules, and explosion-proof configurations. Aligned with the trends of smart buildings, green industries, and intelligent cities, diesel fire pumps have become an indispensable part of high-standard fire protection system designs. Their significance in future firefighting infrastructure will only continue to grow.