Diesel engine fire pump set function description

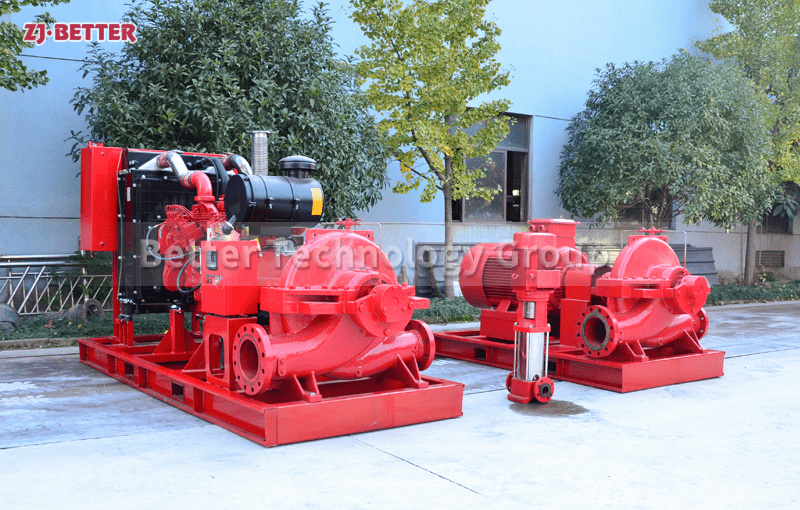

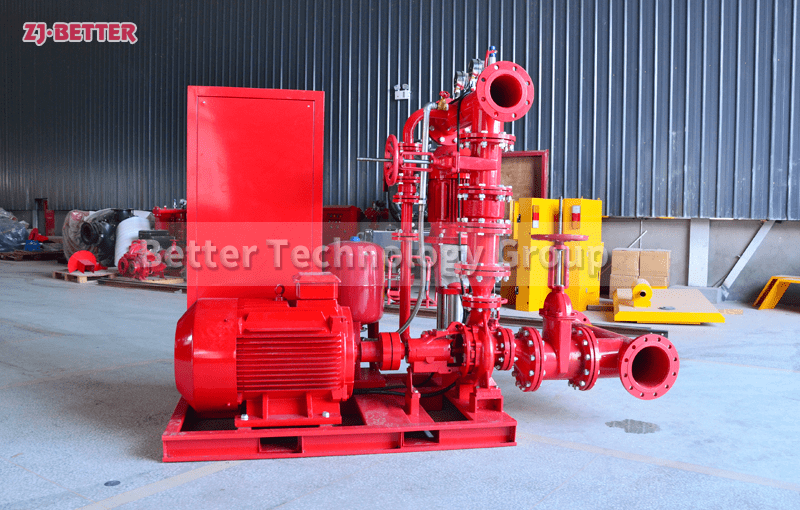

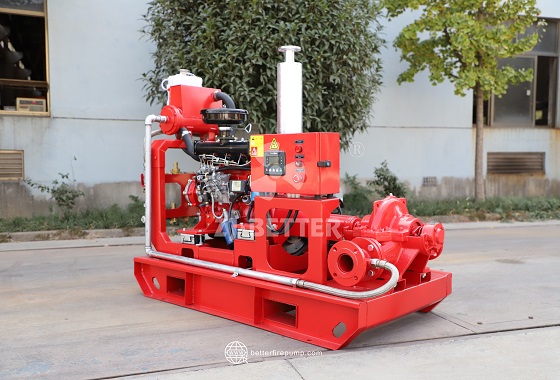

Now the general diesel engine fire pump set is powered by imported or domestic Cummins, Wuxi Power Engine Factory and other diesel engines produced by large-scale key enterprises in the internal combustion engine industry at home and abroad, through highly elastic couplings or diaphragm couplings produced by professional manufacturers. The engine is directly connected with the water pump, and the power of the diesel engine can reach 880KW. It can be equipped with water pumps of different lifts and flow rates for customers to choose and use according to different needs.

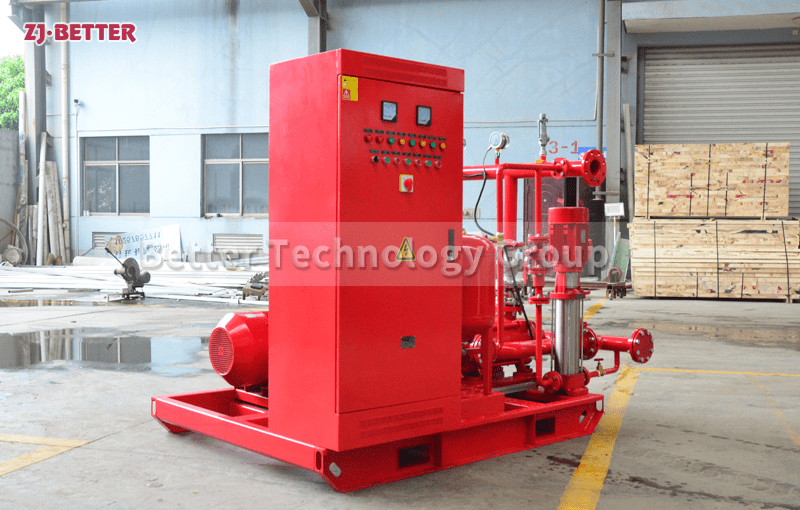

Diesel engine fire pumps can form an automatic water fire water supply system with electric pumps, jockey pumps, etc., and can be linked with the fire control center.

When the diesel engine fire pump set receives the starting command, if the mains power is cut off, the automatic control cabinet of the diesel engine will immediately send a start signal to the starting motor of the pump set, start the motor, start the diesel engine at idle speed, and then gradually adjust the throttle to accelerate the diesel engine until Rated speed. The control system will automatically monitor the operation of the diesel engine, such as the oil pressure, oil temperature, speed of the diesel engine, outlet pressure of the water pump, etc., and determine whether the diesel engine starts normally through automatic monitoring. If the start fails, the control system will send a restart signal, and if the three starts fail, the automatic control system will send a failure alarm. When the diesel engine fire pump set receives a signal that the pressure of the pipe network is restored or the mains power is restored to normal, the pump set will quickly slow down and stop automatically after monitoring the idle position for a period of time.