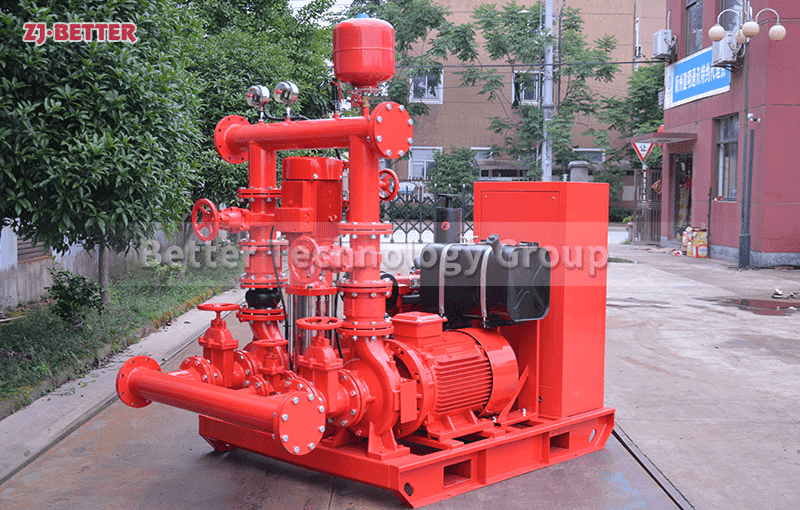

Strictly customized fire pump set according to NFPA 20 requirements

NFPA 20 requires fire pumps to be powered by a continuously available power source, usually identified as an uninterruptible power source. In many cases, this requirement requires a backup generator to be provided as a backup power source in the event of a power failure, in which case the fire pump controller must be equipped with an automatic transfer switch. The choice of fire pump depends on the building infrastructure and available space. The most common choices for fire pump drives are electric motors and diesel engines.

NFPA 20: Fire Stationary Pump Installation Standard protects life and property by providing fire pump installation requirements to ensure the system works as intended, providing an adequate and reliable water supply in the event of a fire emergency.

Usually, the municipal water system has enough pressure to operate a sprinkler system. A fire pump is required when the available water source does not have sufficient pressure. When a sprinkler system relies on a fire pump, the performance of the system depends on the pressure generated by the pump.

-2.jpg)