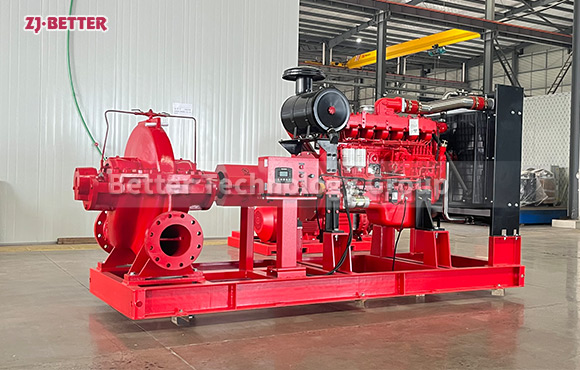

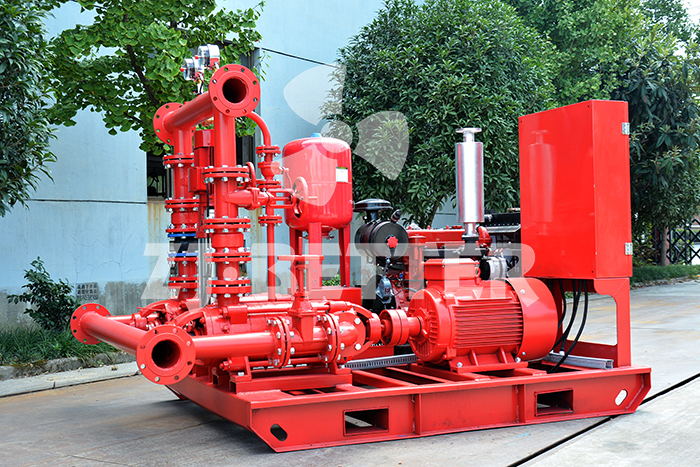

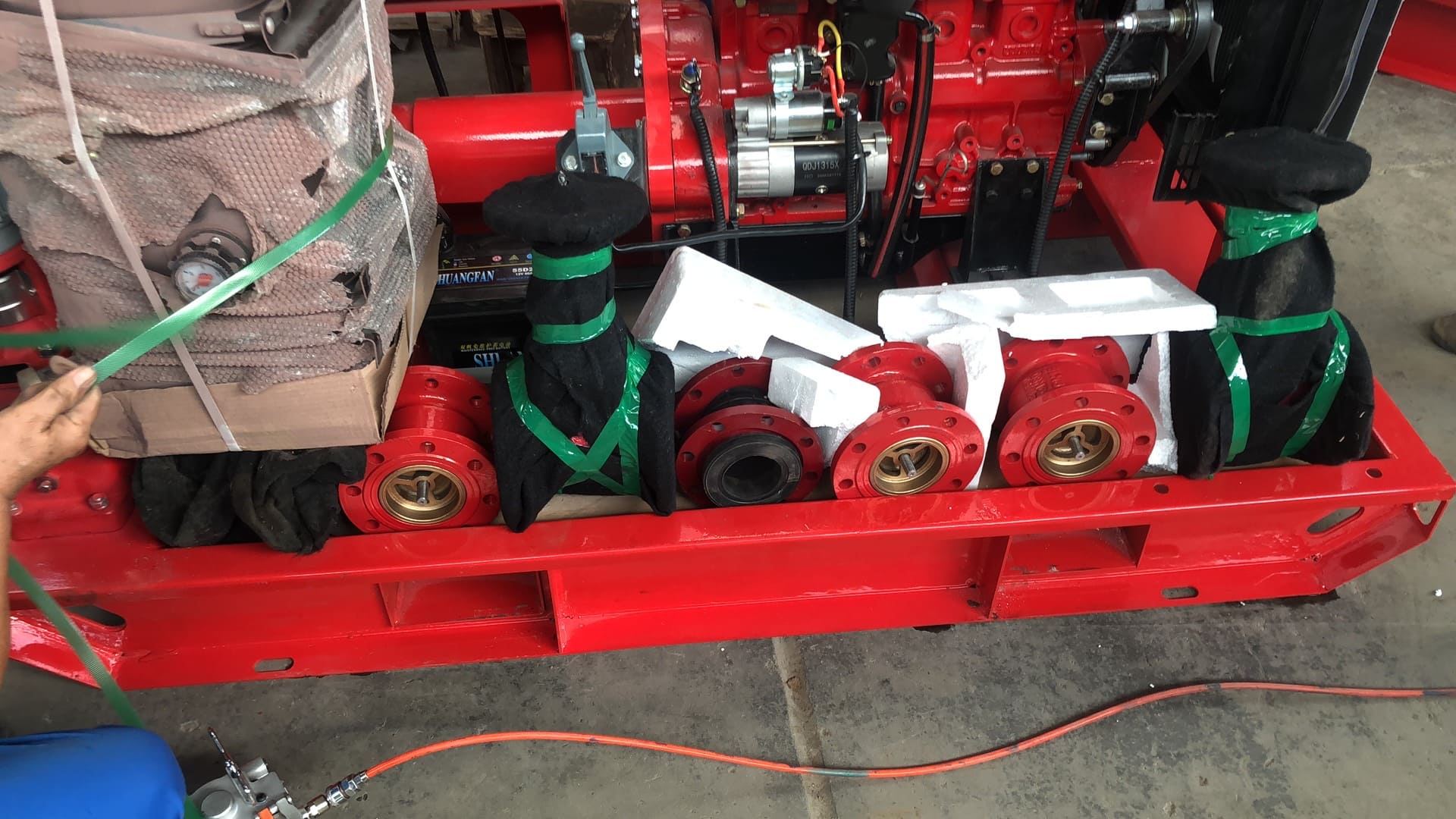

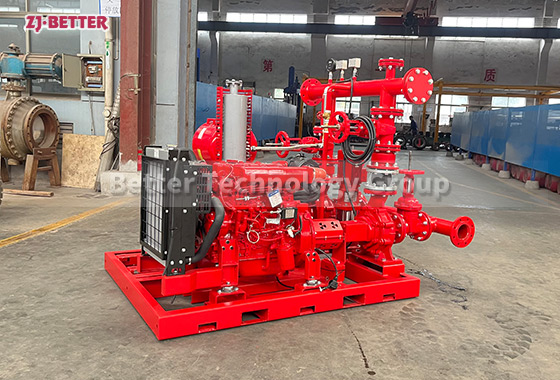

Domestic manufacturers produce EDJ standard fire pump sets

Fire sprinkler systems are an important part of life safety in buildings. International building codes allow some exceptions when buildings are “fully watered”, such as reducing rated spacing, reducing hydrant flow requirements, increasing exit travel distance, and increasing building height and area. These exceptions are allowed so that in the event of a fire, the sprinkler system will suppress the fire enough that occupants can safely evacuate the building and that the spread of the fire is contained before the fire department has fully arrived to extinguish it.

Fire pump: can be divided into two ways, namely automatic start and manual start.

1. Automatic start: When there is a fire danger, we can directly smash the “fire hydrant alarm box” on the floor to give an alarm. At this time, the relevant linkage cabinet will send out a sound and light alarm, so that the fire pump will start again.

2. Manual start: It is also very simple in operation. We need to select the “manual” position on the fire pump control cabinet, and then press the button.