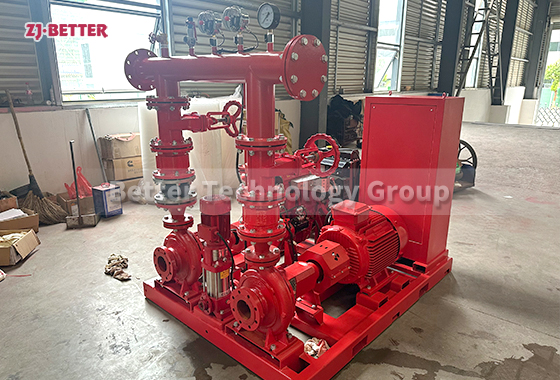

Fire pump group consisting of electric pump + diesel pump + jockey pump

This series of pumps meets the requirements of fire pumps in terms of performance, structure, materials and matching. Due to the use of excellent hydraulic models, this series of pumps has the advantages of meeting user requirements, high efficiency and wide performance range, which can better save floor space; high-quality motors with high-quality bearings make the pump run more safely. Reliable, low noise, low vibration; the use of hydraulic balance axial force can make the operation more stable. The scope of application is suitable for fire water supply in various occasions such as residences, hotels, office buildings, commercial buildings, factories, hospitals, etc.

The EDJ Type model is basically a combination of Electric, Deisel and Jockey pumps. They mainly consist of an electric motor driven end suction pump and a backup pump of a diesel engine driven end suction pump. It is also combined with a jockey pump for maintenance to form a complete skid.

The complete EDJ style skid is assembled with all discharge line fittings and connected to the skid mounted control panel.

Available EDJ-type fire pump skid kits provide the following flows:

50, 120, 150, 250, 300, 350, 500, 750 and 1000 GPM