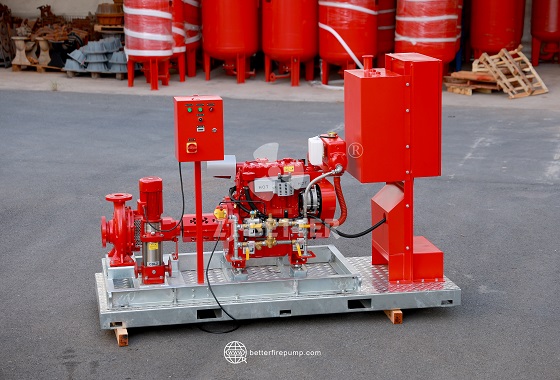

Low Power Diesel Fire Pump Unit for Temporary and Decentralized Projects

Small-power diesel fire pump units are compact in structure and have independent power design. They feature rapid start-up, stable water supply and high reliability. They are suitable for temporary fire protection projects, decentralized fire protection deployment and backup fire protection systems. They can still ensure fire safety and continuous water supply in the event of no power or power outage.

This low-power diesel fire pump unit is a professional fire water supply equipment designed specifically for temporary fire protection projects, decentralized fire station deployments, and applications requiring high installation flexibility and reliability. Its compact structure and high functional integration effectively reduce energy consumption and operating costs while ensuring fire protection performance and stability. It is particularly suitable for rural fire protection, construction sites, warehousing and logistics parks, temporary buildings, decentralized factories, facilities in remote areas, and as a backup or supplementary water supply unit for large-scale fire protection systems. The unit uses a diesel engine as an independent power source, enabling rapid startup and continuous output of stable pressure and flow even in the event of a mains power outage or lack of stable power supply. This ensures that fire water supply is not limited by external energy sources, fundamentally improving the reliability and independence of the fire protection system in the event of a sudden fire. The low-power design does not imply performance compromise; rather, through optimization of the hydraulic model, pipeline layout, and power matching, the pump maintains high efficiency and low energy consumption during long-term operation under rated conditions. This meets the requirements of fire protection codes for startup performance and continuous water supply capacity while avoiding the resource waste that occurs with high-power equipment in small-scale projects. Structurally, the fire pump unit adopts an integrated skid-mounted base design, centrally arranging the diesel engine, water pump, coupling, cooling system, fuel system, and control components on a steel base. This design provides high overall rigidity and excellent seismic resistance, simplifying transportation and installation. It allows for rapid deployment even under tight construction schedules or limited site conditions, significantly shortening project delivery time. The water pump typically utilizes a high-reliability centrifugal pump structure with a rationally designed flow channel, ensuring stable operation over a wide range of conditions. It features minimal water pulsation and stable pressure, facilitating seamless integration with existing fire hydrant or sprinkler systems while reducing pipe impact and valve wear, thus extending the overall lifespan of the fire protection system. The diesel engine has been specifically calibrated for fire-fighting conditions, possessing excellent cold-start performance and continuous operation capability. Even in low-temperature, high-humidity, or prolonged standby conditions, it can quickly respond to start-up commands, ensuring effective water supply pressure is established in the early stages of a fire, buying valuable time for firefighting. The unit’s cooling system fully considers the needs of different operating environments, achieving stable temperature control through a high-efficiency radiator or closed-loop cooling system. This prevents the diesel engine from overheating due to prolonged high-load operation, ensuring consistently stable and reliable power output during continuous fire water supply. Regarding the control system, the small-power diesel fire pump unit is typically equipped with a dedicated fire control box, supporting both manual and automatic start-up modes. When the pipeline pressure drops or a fire alarm signal is received, the equipment automatically starts and enters water supply mode, reducing manual operation and improving system response speed. The control panel has a clear layout, making the operating status, alarm information, and key parameters readily apparent, facilitating daily inspection and maintenance. To adapt to the diverse needs of temporary and decentralized fire protection projects, this type of unit has excellent interface compatibility. Inlet and outlet flange specifications, valve types, and auxiliary pipelines can be flexibly selected according to the actual project conditions, allowing the equipment to quickly integrate into fire protection systems of different scales and types without requiring significant modifications to the existing pipeline network, thus effectively controlling project costs. Durability is also a key advantage of this small-power diesel fire pump unit. Key pressure-bearing and rotating components are made of wear-resistant and corrosion-resistant materials, enabling it to withstand long-term standby and periodic trial operation conditions. This ensures fire safety while reducing the frequency of later maintenance and spare parts replacement costs. For temporary projects or projects with dispersed locations, ease of maintenance is crucial. The unit’s design fully considers maintenance space and operational convenience. Routine inspections, filter replacements, and oil replenishment can all be completed without disassembling the main structure, helping non-professional maintenance personnel to quickly get started and reducing potential equipment hazards caused by improper maintenance. From an application perspective, the small-power diesel fire pump unit can be flexibly deployed on the periphery of buildings, in pump rooms, temporary machine rooms, or open-air protected areas. It can be used as the core equipment of an independent fire water source or as a supplementary unit to the main fire pump system, providing reliable backup during main system maintenance or sudden failures, significantly improving the redundancy and safety factor of the overall fire protection system. Its low power consumption also makes the noise and vibration levels of the equipment relatively controllable during operation. Through reasonable vibration reduction design and noise reduction measures, it can be used in locations with high environmental requirements, minimizing the impact on surrounding work and living environments. Overall, this low-power diesel fire pump unit demonstrates significant advantages in performance stability, environmental adaptability, installation flexibility, and overall cost-effectiveness. It is an ideal choice for temporary fire protection projects, decentralized fire protection layouts, and small-to-medium-scale fire protection projects, balancing safety and economy. It can provide reliable and continuous fire water supply in critical moments, building a solid and efficient safety barrier for different types of fire protection applications.