Lightweight Design Meets Durable Performance: The Core Competitiveness of Portable Fire Pumps

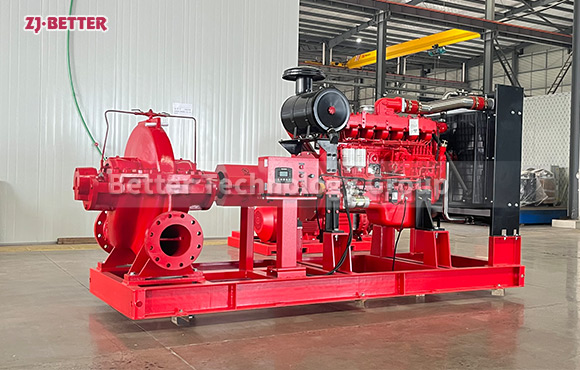

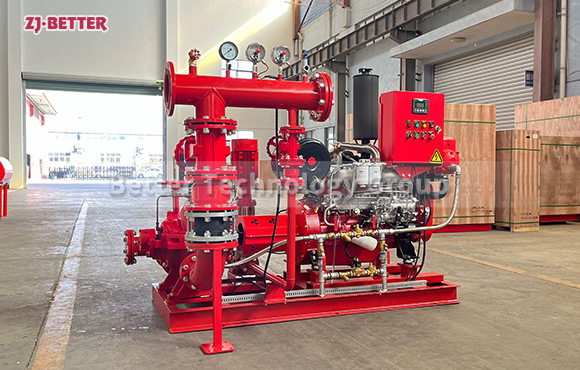

Portable diesel fire pumps are renowned for their high power, mobility, and robust performance, making them ideal for emergency rescue and firefighting scenarios. Their compact design, ease of operation, and quick startup ensure a stable water supply even in power-off environments, helping to improve fire response efficiency and safety.

Portable fire pumps, combining lightweight design with durable performance, are a crucial component of modern firefighting equipment. Their core advantage lies in their perfect balance of portability and efficiency, achieved through scientific structural optimization and a high-performance power system. These devices not only overcome the limitations of traditional fire pumps, such as bulk and transportation difficulties, but also enable rapid deployment in critical moments, ensuring efficient firefighting and emergency water supply. Their compact frame design and controlled overall weight make them easy for one or two people to carry, enabling rapid deployment in buildings, factories, or the field, significantly improving emergency response times. Lightweight doesn’t necessarily compromise performance; on the contrary, optimized pump structure and material selection ensure high strength and corrosion resistance, ensuring stable operation even under long-term, high-intensity operation. Powered by a highly efficient diesel or gasoline engine, portable fire pumps often start quickly and deliver powerful output. They ensure continuous water supply even in power outages or power outages, providing a truly independent and reliable emergency response solution. The pump body is made of high-efficiency impellers and wear-resistant materials, which can establish stable water pressure in a short period of time and maintain a strong flow output. This feature is particularly important in fighting early-stage fires and controlling the spread of fire. Its durability is reflected in many aspects. The first is the choice of materials. The high-strength alloy and corrosion-resistant coating effectively resist the erosion of high temperature, humidity and impure water sources on the equipment. Secondly, the rationality of the structural design ensures the stability and coordination of each component during long-term continuous operation. The third is the optimization of the heat dissipation system to avoid overheating of the engine due to high-load operation, ensuring that the equipment can maintain stable output for a long time. In order to adapt to the needs of multiple scenarios, portable fire pumps usually have good environmental adaptability. Whether it is the narrow passages of urban buildings, field rescue in remote mountainous areas, or the complex working conditions of industrial plants, they can be quickly adapted for use. The protective structure of the equipment also has a certain degree of shock resistance and dustproofness to ensure that it can still maintain normal operation in harsh environments. Ease of operation is also a key advantage. Designed with a focus on human-machine interaction, portable fire pumps feature a clear control panel and convenient startup. Even non-professionals can quickly master their operation in emergency situations, significantly enhancing their feasibility. Compared to traditional fixed fire pumps, portable fire pumps offer significant maintenance advantages. Their simple design facilitates easy access, allowing for quick maintenance such as refueling, oil changes, and filter cleaning, significantly reducing overall ongoing costs. Furthermore, they excel in energy efficiency, with high combustion efficiency and low energy consumption. This ensures reliable operation over extended periods while aligning with current energy conservation and environmental protection trends. As the demand for firefighting and emergency rescue continues to grow, the application areas of portable fire pumps are also expanding. They serve not only as a vital supplement to urban firefighting systems but are also widely used in industrial and mining enterprises, warehousing and logistics, the petrochemical industry, agricultural irrigation, and flood control and emergency response. In areas with limited transportation or lack of fixed water supply, portable fire pumps are becoming virtually the only viable option. In performance testing and actual use, this type of equipment has demonstrated exceptional stability and reliability, maintaining excellent water supply capabilities even during extended periods of operation or frequent starts and stops. This high reliability makes it indispensable for fire departments, factories, and emergency management units. In general, portable fire pumps, by combining lightweight design with durability, address the transportation difficulties and poor adaptability of traditional equipment. While ensuring efficient water supply and powerful power, they also balance affordability and ease of use. They are not only firefighting equipment but also a crucial element in ensuring flexibility, reliability, and efficiency within emergency rescue systems. With the continuous advancement of technology, future portable fire pumps will continue to optimize in terms of intelligent control, remote monitoring, and environmental protection and energy conservation, further enhancing their application value and market competitiveness.