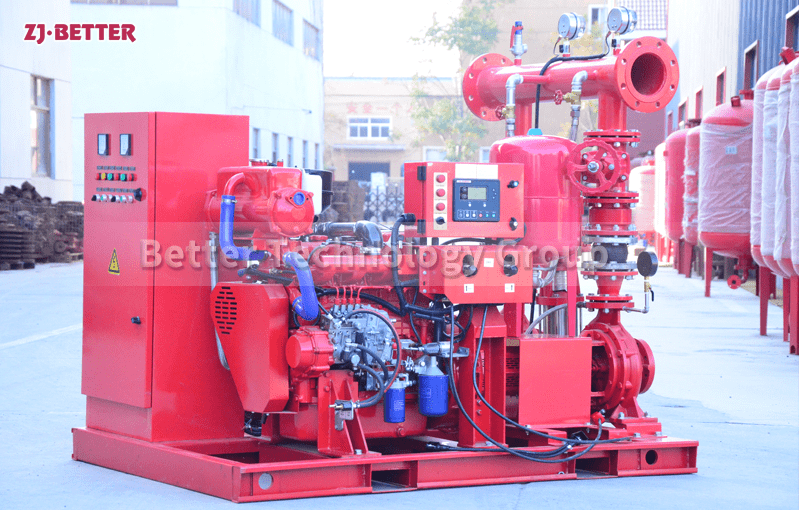

High-Performance Diesel Driven Pump Set – Independent Water Supply in Emergencies

The high-performance diesel-driven fire pump set offers independent power, quick start, and stable operation, ensuring reliable water pressure during power outages or emergencies. Ideal for high-rise buildings, industrial zones, and off-grid areas, it provides efficient, safe, and long-lasting fire water supply protection.

In modern fire protection systems, reliable water supply is a core factor in ensuring firefighting efficiency. Especially during power outages or extreme emergencies, traditional electric fire pumps may be unable to operate due to power failure. In such situations, diesel-driven pump sets demonstrate their irreplaceable importance. High-performance diesel-driven pump sets are fire protection equipment completely independent of external power sources, featuring high power output, rapid start-up, stable operation, and durability. They are widely used in fire water supply systems in high-rise buildings, industrial parks, warehousing and logistics centers, petrochemical bases, ports, and areas without electricity, providing reliable water supply security in critical moments.

The biggest advantage of diesel-driven pump sets lies in their independent power supply capability. When a fire or other emergency causes a power outage, the diesel fire pump can start quickly, providing continuous water pressure and flow to the entire fire protection system. The diesel engine, as the power core, employs efficient combustion technology and a precise fuel injection control system, resulting in high combustion efficiency and rapid start-up response. It can operate stably even in low temperatures or harsh environments. Its powerful performance allows it to reach rated speed quickly, ensuring the pump can be put into operation rapidly and that firefighting operations are not affected by any external factors. This independent power supply mode makes diesel fire pumps a reliable “backbone” for emergency water supply, especially suitable for locations with extremely high safety requirements.

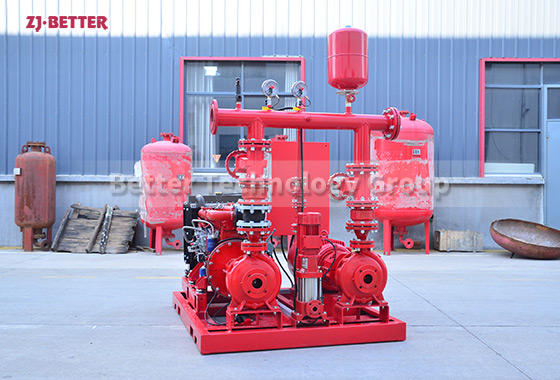

In terms of performance, high-performance diesel-driven pump sets feature high head, large flow rate, and constant pressure output. Through precise hydraulic design and impeller optimization, liquid flow is smoother and energy loss is lower, resulting in higher hydraulic efficiency. The pump body is made of high-strength cast iron or stainless steel, and the internal flow channels are precision-polished and corrosion-resistant, allowing it to withstand high-pressure operation for extended periods without deformation or rust. Whether operating as a single pump or linked with an electric pump, the diesel pump maintains stable output pressure under high load conditions, ensuring continuous water supply during peak fire water usage periods and meeting the simultaneous operation requirements of sprinkler systems, fire hydrant systems, and cooling systems.

Starting performance is one of the key design considerations for diesel-driven pump sets. High-performance units are equipped with a fully automatic control system, enabling one-button start or signal-linked start. When the fire protection system detects a pressure drop or a fire signal, the control system automatically issues a start command, and the diesel engine ignites and starts the pump within a short time. The entire process requires no manual intervention, significantly reducing response time. The control system also features automatic heating, automatic oil replenishment, automatic charging, and self-checking functions, ensuring the equipment is always in optimal standby condition. When power is restored, the system automatically switches back to electric pump operation, achieving intelligent energy management and seamless integration, thus ensuring the fire protection system can operate continuously and stably under any circumstances.

Regarding operational stability, this diesel-driven pump set employs an advanced vibration-damping structure and a high-precision balancing design, ensuring smooth operation with minimal vibration and noise. The engine and pump body are connected by a high-strength coupling, resulting in high transmission efficiency and minimal energy loss. The base uses a thickened steel structure, equipped with vibration-damping pads and fixing bolts, effectively absorbing vibration energy generated during operation, reducing noise transmission, and improving overall stability. This design not only extends the equipment’s service life but also ensures reliable performance under long-term continuous operation, enabling it to provide sustained and stable power support during critical moments.

In terms of durability, every key component of the diesel-driven pump set undergoes rigorous quality inspection and durability testing. The diesel engine is made of high-strength alloy materials, possessing excellent wear resistance, fatigue resistance, and high-temperature resistance. The cooling system is rationally designed with good heat dissipation, enabling long-term operation under high-temperature conditions without overheating. The lubrication system features automatic circulation, reducing mechanical friction, lowering energy consumption, and extending service life. The pump body uses a corrosion-resistant coating process, effectively preventing rust and corrosion even after prolonged contact with water storage tanks or outdoor humid and hot environments. The entire unit maintains a compact design, facilitating maintenance and repair, and ensuring long-term operational stability and economy.

Safety is another key element in the design of the diesel fire pump system. The unit is equipped with multiple safety protection devices, including oil pressure alarm, water temperature alarm, overspeed protection, low speed protection, automatic shutdown at low oil level, and automatic fuel supply cutoff. When the system detects an abnormality, the control system will automatically issue an alarm or execute a shutdown operation to prevent equipment damage and safety accidents. Some models are also equipped with remote monitoring capabilities, allowing real-time monitoring of equipment operating status via a communication module. Data such as speed, oil pressure, water temperature, voltage, and fuel consumption can be monitored, and the unit can be remotely started or stopped, enabling intelligent management and early warning maintenance. This function is particularly suitable for installation in large-scale fire protection systems, facilitating integrated control and centralized management.

Regarding energy conservation and environmental protection, the high-performance diesel-driven pump set adopts a new generation of high-efficiency fuel system, ensuring complete combustion and low emissions, meeting international environmental standards. The engine uses an optimized intake system and precise fuel injection technology, maintaining strong power output while reducing fuel consumption. Some models are equipped with an electronic speed control system, which automatically adjusts the speed according to the load for energy-saving operation. Furthermore, the exhaust system undergoes noise reduction and purification treatment, reducing harmful gas emissions and noise pollution, further aligning with modern green fire protection concepts.

Ease of maintenance and operation is also a significant advantage of this equipment. The unit has a rational layout, with components easy to disassemble and assemble, and ample maintenance space. The control panel is simple to operate, with a clear display that shows operating parameters and alarm information in real time. Maintenance cycles are long; routine maintenance only requires checking the status of fuel, lubricating oil, and coolant, eliminating the need for frequent overhauls. The automatic control system periodically performs self-checks to ensure the unit remains in good working order, reducing manual inspections and saving maintenance costs.

In terms of application, diesel-driven pump sets are widely used in locations with unstable power supplies or requiring independent backup systems, such as airports, docks, warehouses, industrial plants, tunnels, and large commercial complexes. For high-rise buildings, diesel fire pumps can serve as backup power sources, automatically starting water supply when the main power fails; for remote areas far from the city power grid, they are the primary water supply power source, ensuring the fire protection system always has strong water pressure. The flexibility and independence of diesel pumps make them an indispensable component of fire safety systems.

Overall, high-performance diesel-driven pump sets, with their independent power supply capability, strong output performance, rapid start-up response, stable operating characteristics, excellent durability, and intelligent control technology, have become one of the most reliable emergency power devices in modern fire protection systems. They not only provide stable water pressure during power outages but also offer long-term operation and easy maintenance, meeting the fire protection needs of various complex environments. In the future, with the development of intelligent manufacturing and green energy-saving technologies, diesel-driven fire pumps will become more efficient, intelligent and environmentally friendly, playing a more crucial role in ensuring urban and industrial safety and improving emergency response capabilities.