High Head and Large Flow Design for Complex Fire Protection Water Supply Requirements

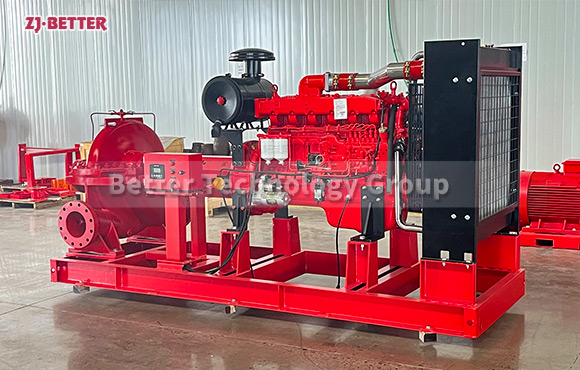

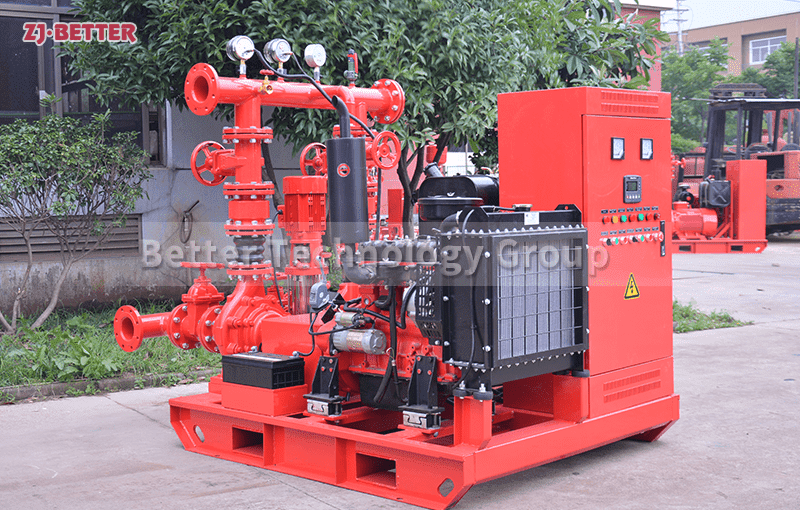

The high-lift, high-flow diesel fire pump is a high-performance device designed specifically for high-rise buildings, industrial facilities, and emergency firefighting systems. It boasts powerful power, fast startup, stable high-voltage output, and can operate independently in powerless environments. Its optimized hydraulic structure combines high lift with high flow, and it offers corrosion resistance, vibration and noise reduction, intelligent control, automatic start-up, efficient and reliable operation, and easy maintenance. It is widely used in building fire protection, petrochemical bases, ports, power plants, and other fields, making it an ideal choice for ensuring fire safety.

High-lift, high-flow diesel fire pumps are high-performance devices designed specifically for complex environments and demanding firefighting systems. Combining a powerful powertrain, sophisticated hydraulics, and reliable control systems, they provide stable and robust firefighting water supply in the shortest possible time. Whether deployed in high-rise buildings, petrochemical bases, ports, power plants, warehouses and logistics centers, or remote industrial areas, these fire pumps demonstrate exceptional efficiency and long-lasting stability. Powered by a highly efficient diesel engine, these pumps offer high torque output, low fuel consumption, and quick start-up. They can operate independently during power outages and harsh environments, providing continuous pressure support for emergency firefighting systems. Their compact design, coupled with a high-strength base and shock-absorbing design, ensures stability even under high loads, low vibration, low noise, and smooth operation, extending their service life. The pump section of these fire pumps typically utilizes a single-stage or multi-stage centrifugal structure. Optimized fluid dynamics ensure smooth water flow and minimize hydraulic losses, significantly improving both lift and flow performance. Its high head allows it to quickly deliver firefighting water over long distances or even to the top floors of high-rise buildings, effectively improving firefighting efficiency. Its high flow rate ensures a powerful water curtain and sufficient coverage in the early stages of a fire, minimizing the spread of fire. The pump body is treated with corrosion and rust prevention, ensuring long-term operation in high humidity, high temperature, and salt spray environments. Internal flow components are constructed of high-hardness alloy or stainless steel, offering excellent wear resistance and maintaining high water delivery efficiency over extended operation. To ensure reliable startup in any emergency, the diesel fire pump is equipped with an intelligent control system that integrates automatic detection, automatic start, pressure monitoring, and fault alarms. If the system detects that the pipeline pressure falls below the set point, the control system automatically issues a start command, immediately activating the diesel engine and driving the pump to deliver high-pressure water, achieving rapid response and automated control. The user-friendly control cabinet features a clear and intuitive interface, allowing for manual, automatic, and remote mode switching, allowing users to flexibly adjust to varying operating conditions and ensure the firefighting system is operational in the shortest possible time. This fire pump was designed with a balance between energy conservation and environmental protection in mind. Its engine boasts high combustion efficiency and emissions that meet international environmental standards, ensuring ample power output while reducing carbon emissions and fuel consumption. The cooling system utilizes efficient air or water cooling, enabling the engine to maintain an ideal temperature even in high-temperature, continuous operating environments, preventing performance degradation due to overheating. The lubrication and fuel systems are rationally designed, offering simple maintenance, a long service life, and stable, reliable operation over the long term. Its transmission system and couplings are precisely balanced to ensure efficient and lossless energy transfer, significantly improving overall mechanical efficiency. For installation, the pump unit typically utilizes a monolithic base structure and is shipped pre-assembled and aligned. Users simply connect the inlet and outlet water pipes and oil system to the system, significantly reducing on-site installation and commissioning time. The unit also includes multiple interfaces for adding pressure-stabilizing pumps, sprinkler systems, or backup electric pumps to meet diverse project requirements, enabling flexible fire protection system configurations that meet diverse project standards and fire regulations. In terms of safety, this fire pump features multiple protections, including low oil pressure protection, high water temperature alarm, overspeed protection, and start-up failure protection. These automatically shut down or sound an alarm in any abnormal situation, preventing equipment damage and ensuring operator safety. Its waterproof and dustproof electrical system is suitable for long-term use in outdoor and harsh environments, ensuring exceptional reliability. In addition to its traditional application in building fire protection systems, high-lift, high-flow diesel fire pumps are also widely used in municipal water supply, mine drainage, agricultural irrigation, and emergency flood control. Their powerful power and independent operation capabilities ensure stable water supply even in remote, powerless areas, making them a crucial component in ensuring the safe operation of infrastructure. Over long-term operation, their high-strength bearings and sealing system effectively prevent leakage and wear, significantly reducing maintenance costs. Regular oil and filter changes maintain optimal performance, resulting in long maintenance intervals and minimal maintenance effort, meeting the demands of modern engineering projects for efficient and reliable equipment. Notably, this series of fire pumps undergoes rigorous factory testing, including performance testing, pressure resistance testing, start-up time testing, and flow-head curve verification, to ensure that each unit meets international fire protection standards. Its smooth performance curve and stable water pressure output prevent flow rate dropout or pressure fluctuations even during long-term continuous operation, making it particularly critical for firefighting water supply maintenance. During emergency operations, it can start up in tens of seconds and seamlessly transition from standstill to full-load operation, significantly improving firefighting response times. For users, this equipment not only represents a reliable firefighting solution but also a long-term investment with high efficiency and low energy consumption. Through advanced manufacturing processes and rigorous quality control, this high-lift, high-flow diesel fire pump leads the industry in performance stability, reliability, and service life. Its combination of high power, high-pressure resistance, easy maintenance, and rapid response make it the preferred solution for large-scale firefighting systems, industrial facilities, and high-risk locations. Whether in routine firefighting standby or emergency rescue operations, it delivers a continuous, stable water flow under the most demanding conditions, providing a solid foundation for protecting life and property.