Choosing the Right Fire Pump: EDJ Fire Pump – ZJBetter

Fire pumps are part of the water supply to a fire sprinkler system and are powered by electricity or diesel. The pump inlet is either connected to a public groundwater supply or to a static water source (e.g. tank, reservoir, lake). This pump provides higher pressure water flow to sprinkler system risers and hose risers.

Our factory can manufacture NFPA20 compliant fire pumps.

Fire pumps can function with electric motors or diesel engines, and if local building codes require electricity independent of the local grid, pumps using electric motors can use the installation of an emergency generator when connected through a transfer switch listed.

Fire pump kits include a combination of electric pumps, diesel engine driven and electric motor driven jockey pumps for use in fire suppression systems.

Fire pump packages must comply with local Civil Defense regulations and international codes of practice, such as the National Fire Protection Association (NFPA).

Pump types used in fire service include: end suction, horizontal split, vertical split, vertical inline and vertical turbine.

1. Electric pump, single-stage pump, horizontal split pump, end-suction pump, multi-stage pump can be used, and the material can be cast iron, stainless steel, bronze impeller

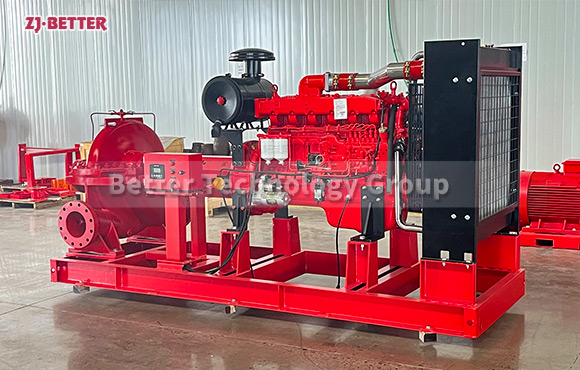

2. Diesel engine pump, capacity and lift equal to electric pump, with fuel tank, water tank fan, control box

3. Pipeline pressure pump, horizontal or vertical, with small capacity, but the lift should be higher than that of electric and diesel pumps

4. Control panel: automatic control of electric pump, diesel engine pump and pipeline pressure pump, with overload and overcurrent protection

5. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, pressure gauge, pressure sensor, shared suction and exhaust pipes, flexible joints and flanges, and shared base device.