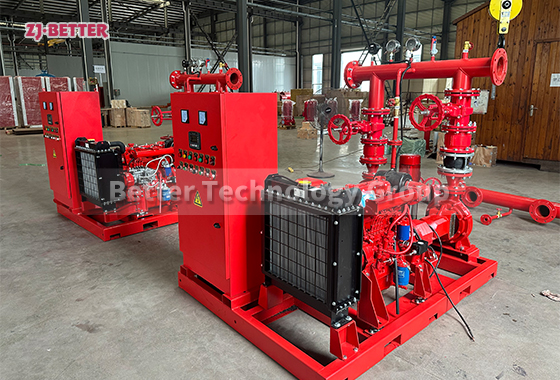

Innovative Electric Fire Pump Set – Dual Assurance of Efficient Operation and Easy Maintenance

Electric fire pump units are efficient, intelligent, and energy-saving fire-fighting water supply equipment, featuring stable water pressure output, low noise, easy maintenance, and long service life. Their automated control system enables remote monitoring and intelligent start-up, making them suitable for high-rise buildings, industrial plants, warehousing centers, and other locations. They ensure continuous water supply and safe operation during fires, providing reliable protection for modern fire protection systems.

Electric fire pump units are high-performance water supply equipment designed specifically for modern building and industrial fire protection systems. With their stable electric drive, efficient hydraulic performance, and intelligent control system, they have become the core power supply equipment in various fire protection scenarios today. With the rapid development of industrialization and urbanization, the safety, reliability, and intelligence level of fire water supply systems have become important standards for measuring the maturity of a building or factory’s fire protection system, and electric fire pump units are crucial support equipment for achieving this goal. They utilize high-efficiency motor drives, combined with a scientific pump body structure and advanced control devices, to provide strong and stable water pressure immediately upon the occurrence of a fire, ensuring continuous water supply for sprinklers, fire hydrants, and other fire protection equipment. The electric fire pump unit is designed with the needs of different application environments in mind. Its innovative structure enables the equipment to operate with high efficiency, low noise, and low vibration. The pump body is made of high-quality cast iron or stainless steel, ensuring corrosion and wear resistance during long-term operation and adaptability to various water media and environmental conditions. The motor uses high-performance insulation materials and a high-temperature resistant winding structure, which not only extends the equipment’s lifespan but also maintains high energy efficiency output during long-term high-load operation. Its high-precision impeller design ensures smooth fluid flow and high head output, enabling the pump unit to maintain excellent energy efficiency even under high-pressure water supply conditions. In terms of the control system, electric fire pump units are typically equipped with intelligent control cabinets, enabling fully automatic start-up, remote monitoring, and status alarm functions. The system can monitor key parameters such as motor current, voltage, temperature, pump body pressure, and flow rate in real time. When abnormalities occur, such as overload, phase loss, low pressure, or overheating, the system will automatically issue an alarm and take protective measures, effectively preventing equipment damage. This intelligent control method not only makes the electric fire pump unit safer to operate but also greatly reduces the complexity of manual maintenance, improves the system’s automation management level, and meets the needs of modern fire protection systems for intelligent monitoring and remote control. Furthermore, the electric fire pump unit offers flexible and diverse starting methods, including direct start-up or smooth start-up and shutdown via soft starters or frequency converters, avoiding the current surge problems of traditional motor start-up and extending the service life of the motor and piping system. The application of frequency conversion control technology allows the pump unit to automatically adjust its speed according to system pressure changes, achieving constant pressure water supply and energy-saving operation. When the system is in standby or low-demand state, the pump unit can automatically reduce power output, significantly reducing energy consumption. This energy-saving control mode aligns with today’s green environmental protection and sustainable development concepts, and also reduces long-term operating costs. The electric fire pump unit has a compact installation structure and small footprint, making it particularly suitable for high-rise buildings, underground garages, factories, warehousing centers, and industrial sites such as petrochemical, metallurgical, and power plants. Its modular design facilitates transportation and rapid installation, and the main pump, pressure-stabilizing pump, control cabinet, pressure-stabilizing tank, and piping accessories can be flexibly configured according to project needs to meet different pressure and flow requirements. The entire pump unit undergoes rigorous factory testing to ensure that every component operates in harmony during system operation, thereby achieving efficient and stable overall performance. In terms of maintenance, the electric fire pump unit’s design fully embodies the concept of “easy operation and easy maintenance.” The pump body structure is easy to disassemble and assemble, and key components such as impellers, shaft seals, and bearings can be quickly replaced without complex tools or prolonged downtime. The lubrication system adopts an automatic lubrication design, reducing manual maintenance cycles; at the same time, the noise and vibration levels during equipment operation have been optimized to reduce the impact on the surrounding environment. The control system features a user-friendly human-machine interface, allowing users to view operating data, historical records, and alarm information via touchscreen or remote terminal, greatly enhancing the convenience of equipment management. The high reliability of the electric fire pump unit is one of its most prominent features. It employs a high-strength mechanical seal and a high-protection-level motor structure, enabling stable operation in humid, high-temperature, or dusty environments. Even in extreme environments such as fires, the pump unit maintains continuous output, ensuring the immediate response of the fire protection system. Some models also feature automatic switching functionality, seamlessly connecting with a backup power system or emergency diesel pump in the event of a main power failure, further enhancing system redundancy and safety. This multi-layered safety protection design ensures the electric fire pump unit maintains high stability and reliable operation under various complex working conditions. In terms of performance, the electric fire pump unit typically has a head ranging from tens to hundreds of meters, a wide flow range, and can be customized to meet different project requirements. Its efficiency is over 80%, demonstrating excellent energy conversion capabilities. The pump set can transport clean water or mildly corrosive liquids, operates smoothly, and maintains stable output pressure, effectively ensuring rapid water supply to fire sprinkler and fire hydrant systems in the early stages of a fire. For large public buildings or industrial plants, this high-performance pump set can provide continuous water support at critical moments, making it an irreplaceable core piece of equipment in fire protection systems. The electric fire pump set also boasts superior energy-saving characteristics. Under the same flow rate and head conditions, its energy consumption is significantly lower than that of traditional fire pump systems. Through optimized fluid dynamics design and the use of a high-efficiency motor, hydraulic losses and electrical energy consumption are reduced, resulting in a significant improvement in overall system efficiency. Some pump sets also employ intelligent load control technology, which can dynamically adjust power output according to actual working needs, achieving optimal energy utilization. This energy-saving design not only reduces operating costs but also reduces environmental impact, meeting the requirements of modern green building and energy conservation and emission reduction. From an application perspective, the electric fire pump set is suitable for almost all fire protection systems requiring reliable water supply. Whether it’s automatic sprinkler systems in high-rise buildings, fire hydrant systems in underground garages, or industrial scenarios such as petrochemical tank areas and power plant cooling zones, it can provide strong water pressure with stable performance. Its diverse models and flexible parameter configurations allow engineers to select the most suitable solution based on site conditions, achieving optimal system matching and thus improving the operational efficiency and safety of the entire fire protection system. The manufacturing process of electric fire pump units strictly adheres to international fire protection standards and quality systems. From raw material selection and component processing to complete assembly and testing, multiple inspections and quality controls are implemented to ensure the product is in optimal operating condition upon delivery. Its reliable performance, intelligent control system, and long service life make it a trustworthy water supply device in various fire protection systems. Overall, electric fire pump units not only embody the advanced technology of modern fire protection equipment but also bring long-term value to users in terms of practicality and economy. In the future, with the development of smart fire protection and intelligent manufacturing, electric fire pump units will continue to evolve towards higher efficiency, intelligence, and energy conservation, providing a more solid power guarantee for global fire safety.