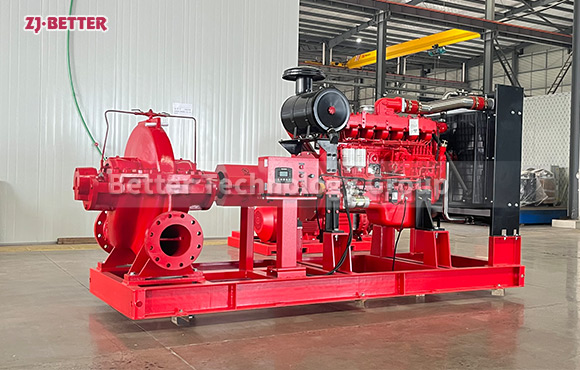

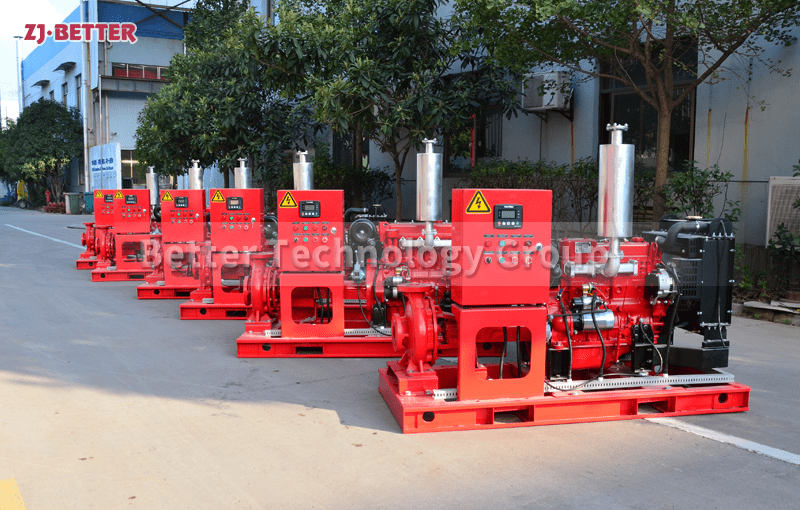

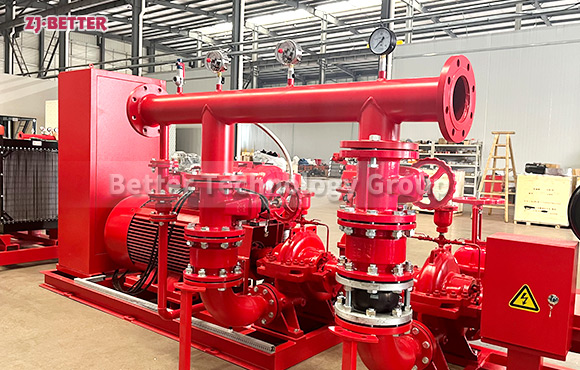

Pre-Assembled Fire Pump Package with Piping for Easy Installation

Pre-assembled fire pump packages with integrated piping designed for fixed fire protection projects, offering easy installation, stable performance, reduced on-site work, and reliable water supply for hydrant and sprinkler systems.

Pre-installed pipeline fire pump systems are highly integrated fire water supply solutions designed with engineering efficiency and operational reliability as core objectives. They are widely used in various fixed fire protection projects, and are particularly suitable for buildings and industrial sites with high requirements for installation time, system stability, and operational consistency. Before leaving the factory, these systems have completed the overall integration and commissioning of the fire pump, power system, control cabinet, valve components, instruments, and inlet/outlet pipelines, forming a complete and functional unit. On-site installation only requires foundation fixing and interface connections, fundamentally reducing potential system hazards caused by inconsistent on-site construction skills during traditional decentralized installations. The pre-installed pipeline structure is one of the most significant advantages of these fire pump systems. Through standardized design and factory manufacturing processes, complex pipeline connections, valve configurations, and measuring instruments are concentrated within a limited space. This not only significantly reduces on-site construction intensity but also effectively avoids leakage, vibration, and pressure loss problems caused by unreasonable pipeline layout, unstable welding quality, or inadequate sealing. As the core component of the system, the selection and performance design of fire pumps are strictly based on fire-fighting conditions. The pump body is typically made of high-strength, pressure-resistant materials, and the internal flow channels are meticulously hydraulically designed. While ensuring rated flow and head output, it also considers operational efficiency and stability, maintaining reliable performance under long-term standby and sudden high-load operation conditions, and is less prone to efficiency degradation or abnormal vibration. Pre-installed pipeline fire pump systems emphasize compactness and rationality in their overall structural design. The functional modules are clearly distributed, and the relative positions between the pump body, pipelines, valves, and control system are optimized. This ensures smooth system operation and provides ample space for later inspection and maintenance, making daily inspections and periodic maintenance more convenient. Ease of installation is one of the key reasons why this type of equipment is highly favored in engineering projects. Compared to traditional on-site assembly, pre-installed pipeline systems can significantly shorten the construction cycle and reduce reliance on highly skilled welding and complex commissioning procedures. This is particularly suitable for projects with tight schedules or limited construction conditions, and also facilitates unified quality control of the overall project. As a crucial component of the complete set of equipment, the control system is typically integrated into a separate electrical control cabinet. It features automatic start/stop, operational status monitoring, and fault alarm functions, enabling rapid response and stable control based on the actual needs of the fire protection system. In the event of a fire, it quickly activates the fire pump, ensuring uninterrupted fire water supply. The accompanying valves and instrumentation systems are pre-configured and calibrated at the factory. The positions of pressure gauges, flow monitoring points, and various control valves are scientifically designed, meeting regulatory requirements and facilitating real-time monitoring of system operation by operators, thereby enhancing the overall controllability and safety of the fire protection system. From an operational performance perspective, pre-installed pipeline fire pump systems offer significant advantages in stability and consistency. Because key components and connection points are installed and tested in a controlled factory environment, the overall system performance is more balanced, effectively reducing the impact of uncertainties during on-site construction on operational quality. During long-term operation, the equipment exhibits excellent vibration and shock resistance. The reasonable pipeline support and fixing methods maintain structural stability during fire pump start-up and shutdown, reducing the impact of mechanical stress on equipment lifespan. For different application scenarios, this type of complete set of equipment can be flexibly matched with fire hydrant systems, automatic sprinkler systems, or other fixed fire protection facilities. By reasonably configuring pump type, flow rate, and pressure rating, it can meet diverse engineering needs. Pre-installed pipeline fire pump complete sets of equipment also have significant advantages in saving labor costs. Due to the substantial reduction in on-site installation and commissioning work, it effectively reduces the investment of construction personnel and the risk of rework later, while also reducing the coordination difficulty in project management, providing greater certainty for the overall project progress. In terms of safety, this type of equipment fully considers the high requirements of fire protection systems for reliable operation during the design phase. Key components adopt redundant designs or reinforced structures to ensure stable operation even under extreme conditions. Combined with comprehensive electrical and mechanical protection measures, it provides multiple safety guarantees for the fire water supply system. In summary, pre-installed pipeline fire pump complete sets of equipment, through highly integrated structural design, stable and reliable operating performance, and significantly improved installation convenience, effectively solve the pain points of traditional fire pump systems in terms of construction efficiency and operational consistency. It has become an increasingly important solution in modern fixed fire protection engineering, providing an efficient, reliable, and easy-to-manage fire water supply foundation for various building and industrial projects.