Industrial-Grade Vertical Centrifugal Fire Pump: Reliability and Easy Maintenance Combined

High-efficiency vertical centrifugal fire pumps are designed specifically for various types of buildings, industries, and fire protection systems. They offer high head, large flow, low energy consumption, and a compact structure. They support intelligent control and multi-stage configuration, offer stable and reliable operation, and are easy to maintain. They meet international fire protection standards and are an ideal fire water supply solution for high-rise buildings and industrial facilities.

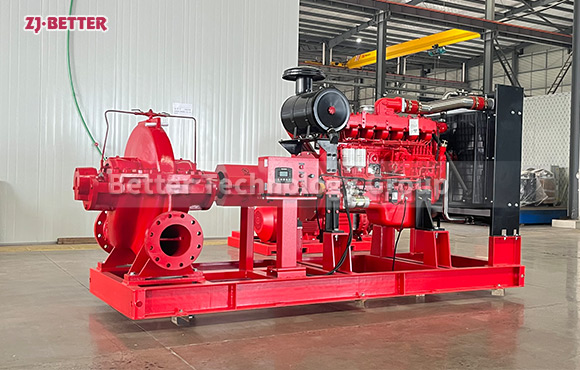

Industrial-grade vertical centrifugal fire pumps are high-performance equipment designed for large-scale fire protection systems, industrial water supply systems, and building fire protection projects. With its stable structural design, powerful power output, and excellent operating efficiency, they are the core force for ensuring fire safety and continuous water supply. This vertical fire pump features a compact footprint and is easy to install and maintain, making it particularly suitable for fire pumping stations in space-constrained equipment rooms or high-rise buildings. Its overall design complies with international fire protection standards, ensuring efficient and stable operation even under extreme conditions, ensuring sufficient and continuous water pressure support for fire protection systems in emergency situations. The greatest advantage of industrial-grade vertical centrifugal fire pumps lies in their high efficiency and reliability. The pump body is constructed of high-strength cast iron or stainless steel, precision-cast, and dynamically balanced, offering excellent wear and corrosion resistance. It can operate stably in water sources containing trace impurities or mild corrosion. The pump shaft undergoes a special heat treatment and rust-proof coating process to ensure smooth operation, low vibration, and low noise, extending the service life of the equipment. The motor features an efficient and energy-saving design, with speed precisely matched to the pump body, minimizing energy loss, thereby improving overall efficiency and reducing operating costs. The control system is a key highlight of this industrial-grade vertical centrifugal fire pump. Its intelligent control panel monitors the equipment’s operating status in real time, including parameters such as water pressure, flow, current, and temperature. It also features automatic start-up, automatic switching, and fault alarms. In the event of a fire or a drop in water supply pressure, the system automatically responds within seconds, rapidly starting the pumps and ensuring uninterrupted fire water supply. The control system also supports remote monitoring and data transmission, allowing users to access real-time equipment status via a computer or mobile device, enabling intelligent operation and maintenance. This advanced control technology ensures that the fire pump not only starts quickly during fire emergencies but also maintains optimal operating conditions during daily operation. The industrial-grade vertical centrifugal fire pump offers exceptional hydraulic performance. Its optimized hydraulic model design results in smooth flow paths, effectively reducing water resistance and improving head and flow stability. With a maximum operating efficiency exceeding 85%, the pump provides stable water pressure with minimal fluctuations, meeting the fire water needs of large and medium-sized buildings, warehouses and logistics centers, factories, airports, and docks. For high-rise buildings, this pump’s multi-stage configuration enables high-lift water supply, ensuring balanced firefighting water pressure from the ground floor to the top floor, providing strong support for fire sprinkler and fire hydrant systems. Furthermore, this pump can be integrated into a complete firefighting system with diesel-driven pumps, electric pumps, or pressure-stabilizing pumps, achieving multi-energy redundancy and further enhancing system reliability. Ease of maintenance is a key factor in attracting users to industrial-grade vertical centrifugal fire pumps. The pump’s compact design and top-inlet, bottom-outlet, or coaxial connection eliminate the need for adjusting the pump and motor’s coaxiality. Disassembly requires only the pump cover to access the impeller, shaft seal, or mechanical seal, significantly reducing maintenance time and labor costs. The mechanical seal is constructed of high-temperature and corrosion-resistant materials, ensuring long-term sealing performance and effectively preventing leakage, ensuring stable operation even under high-pressure conditions. Furthermore, an automatic lubrication system and cooling device ensure that all moving parts maintain optimal operating conditions even under high loads. Regarding safety, the design of this industrial-grade vertical centrifugal fire pump fully considers reliability and emergency response capabilities under various operating conditions. The pump unit is equipped with multiple safety features, including optional overload protection, water shortage protection, and overheating protection. When the system detects an anomaly, it automatically generates an alarm or shuts down to prevent equipment damage. Furthermore, its electrical control system meets international protection standards, offering waterproof, dustproof, and shockproof features, making it suitable for long-term operation in a variety of harsh environments. The pump unit’s reinforced base provides excellent shockproofing, ensuring stable operation and preventing system failures caused by vibration. Energy conservation and environmental protection are also prominent advantages of this product. The efficient matching between the pump body and motor significantly reduces energy consumption. The low-noise design and construction of environmentally friendly materials meet the requirements of green energy-saving building standards. Compared with traditional horizontal fire pumps, the vertical structure not only reduces mechanical losses but also lowers overall energy consumption, significantly reducing operating costs over the long term. Its energy-saving features have made it widely used in modern urban fire protection systems, industrial parks, and smart buildings. This pump also offers excellent adaptability, offering various flow and head configurations to meet user needs, suitable for conveying clear water, slightly impure water, and mildly corrosive media. It is suitable for use in standalone fire protection systems or in conjunction with water supply systems, enabling flexible switching between emergency and domestic water supply. To meet global market demands, the product has obtained multiple international certifications and complies with NFPA, ISO, EN, and other standards, ensuring legal and reliable use in different countries and regions. For users, the industrial-grade vertical centrifugal fire pump is more than just a piece of equipment; it is a safeguard. Its design concept is centered around the four core elements of “efficiency, safety, intelligence, and durability.” It achieves outstanding performance through the combination of high-quality materials, high-standard craftsmanship, and a high-tech control system. In modern fire protection projects, this vertical centrifugal pump, with its rational structure, stable performance, easy installation, and simple maintenance, has become the preferred equipment for various demanding fire protection systems. Whether in commercial complexes, petrochemical plants, power facilities, or public buildings, it can provide stable and reliable water supply, providing a solid foundation for fire safety. In summary, the industrial-grade vertical centrifugal fire pump is an advanced fire protection device that combines high efficiency, intelligent control, energy saving and environmental protection, and a compact structure. It not only improves system operating efficiency but also reduces maintenance and operating costs, truly achieving dual optimization of performance and economy. With the rapid development of urbanization and industrialization, fire protection systems are placing increasing demands on water supply equipment. This vertical centrifugal fire pump, with its superior performance and reliable quality, is becoming an indispensable core power unit in modern fire protection systems, safeguarding fire safety worldwide.