Vertical Pressure Tank System: A Compact and Stable Fire Pressure Solution

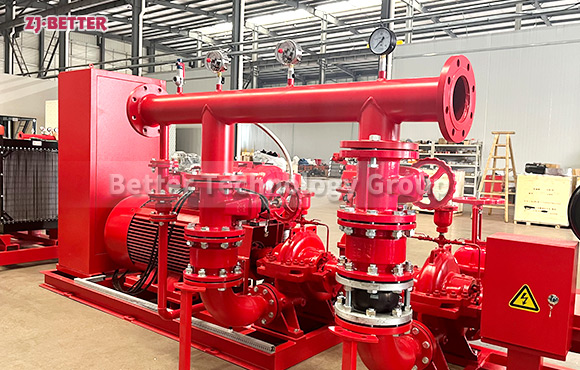

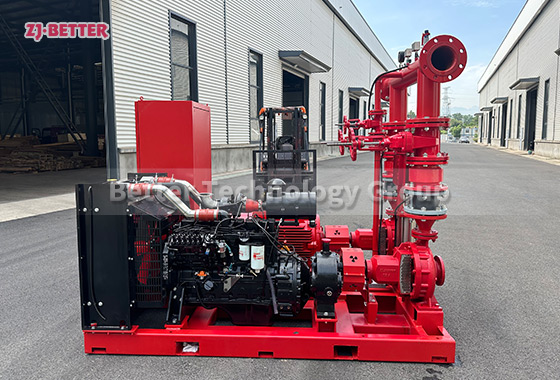

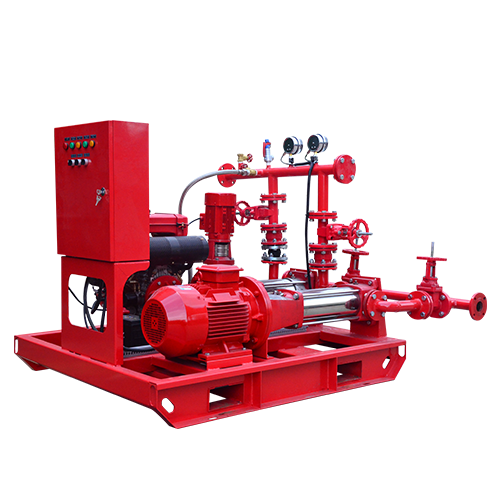

The vertical pressure-stabilizing tank system is a highly efficient and intelligent fire-fighting pressure-stabilizing device with advantages such as automatic pressure regulation, energy-saving operation, small footprint, and easy maintenance. It is widely used in high-rise buildings, industrial plants, underground garages, and public facilities. It provides continuous and stable water pressure support for fire-fighting pipe networks, ensuring rapid system response and safe and reliable operation. It is an ideal choice for modern fire water supply systems.

The vertical pressure-stabilizing tank system is a fire-fighting pressure-stabilizing device that combines efficient pressure supply, intelligent control, and a compact structure. Designed specifically for various fire water supply systems, it maintains constant pressure in the firefighting network during non-fire conditions, ensuring that the main pump can quickly start and provide sufficient water pressure support when needed. The system utilizes advanced air pressure balancing technology and automatic control devices to achieve real-time pressure monitoring and automatic adjustment, saving energy while extending the service life of the main pump and related equipment. Its vertical structure allows for a small footprint and flexible installation, making it suitable for a variety of scenarios, including high-rise buildings, underground garages, industrial plants, storage bases, and large public facilities. The core components of the vertical pressure-stabilizing tank system include a high-strength air pressure tank, a pressure-stabilizing pump assembly, a pressure control system, a sensor unit, and safety accessories. The air pressure tank is constructed of welded carbon steel or stainless steel and features a high-strength diaphragm or bladder inside to separate the gas and water, thereby creating a stable air-water interface. When system pressure drops, the compressed air within the tank automatically releases energy, pushing the water to compensate for the system pressure. When the pressure drops further to the set lower limit, the pressure-stabilizing pump automatically activates to restore the water pressure to normal, and automatically stops when the upper limit is reached. This operating mode not only significantly reduces the number of main pump starts but also effectively prevents equipment wear and increased energy consumption caused by frequent starts and stops. The vertical design is a key advantage of this system. The vertical arrangement ensures uniform force distribution within the tank, enhancing stability and allowing it to withstand higher operating pressures while reducing installation space requirements. Compared to horizontal tanks, vertical pressure-stabilizing tanks achieve more pronounced gas-water stratification, resulting in more efficient gas compression and water expansion, thus improving pressure stabilization. The base features an integrally reinforced design and anti-vibration support structure, ensuring stable operation despite frequent starts and stops. The system’s exterior is treated with an anti-corrosion spray coating, providing excellent weather and moisture resistance, allowing for long-term use in indoor or semi-outdoor environments. The pressure-stabilizing pump for a vertical surge tank system typically uses a high-efficiency vertical multi-stage centrifugal pump or pipeline centrifugal pump. The pump body and impeller are constructed of stainless steel or high-strength alloys, offering high head, low noise, and long life. The motor is fully enclosed and protected, offering waterproof, dustproof, and high-temperature resistance, adapting to continuous operation in diverse environments. Pump startup is automatically performed by an intelligent control system. The controller determines the need for pump startup in real time based on pressure fluctuations and automatically starts and stops the pump according to pre-set parameters, ensuring optimal pipe network pressure. The control system utilizes a PLC module or microcomputer logic controller, combined with high-precision pressure sensors and a signal feedback unit, for intelligent management of the entire system. The system offers manual, automatic, and remote operation modes, supporting multi-point monitoring and parameter setting. The intuitive user interface displays real-time data, including system pressure, pump operating status, start and stop history, and alarm information, making it easy for users to monitor operational status. The control system also incorporates multiple protection features, including phase loss protection, overvoltage protection, low-pressure alarm, overtemperature protection, and dry-run protection, ensuring safe and stable operation under various operating conditions. To further enhance automation, the system features an optional remote monitoring module, connecting to the fire control center via IoT communications. Users can remotely view operating status, historical records, and alarm information via a computer or mobile device, significantly improving equipment manageability and safety. The vertical surge tank system also excels in energy conservation and environmental protection. Because the energy storage function of the pressure tank maintains system balance, the surge pump can remain stopped for extended periods when there are no pressure fluctuations, operating only briefly when needed, significantly reducing power consumption. Reduced system startup frequency also reduces mechanical wear and maintenance workload, extending equipment life and lowering operating costs. Furthermore, the pump and tank bodies offer excellent sealing performance, resulting in virtually no leakage or noise pollution during operation, in line with the design principles of modern green and energy-saving buildings. To ensure high equipment safety, the vertical surge tank system is equipped with multiple safety measures. A safety valve and pressure gauge on the top of the pressure tank monitor internal pressure changes at all times to prevent overpressure. A drain valve and inspection port on the bottom facilitate routine maintenance and cleaning. The system undergoes rigorous pressure and airtightness testing before shipment to ensure long-term safe operation even under high pressure. Some models also have a self-diagnosis function. When abnormal pressure fluctuations or pump group failures occur, it will automatically alarm and switch to backup mode to ensure continuous and reliable pressure supply for the fire protection system. The convenience of installation and maintenance is another notable feature of the vertical pressure-surge tank system. The overall equipment adopts a modular design, which is convenient for transportation and installation and can be flexibly arranged according to the on-site space. Because the vertical structure occupies a small area, it is particularly suitable for construction projects with limited machine room space. During installation, it only needs to connect the inlet and outlet water pipes, power supply and signal lines to be put into use. The construction period is short and the debugging is simple. The system requires almost no manual supervision during operation. The control system can automatically record the operating time and prompt the maintenance cycle, reminding users to regularly check the tank air pressure and pump group status, thereby reducing operation and maintenance costs. The vertical pressure-surge tank system has demonstrated excellent adaptability and stability in various application scenarios. In high-rise buildings, it ensures that fire hydrants and sprinkler systems maintain adequate water pressure. In industrial plants, it can operate in conjunction with the main pump system to provide continuous and stable water supply to production areas or hazardous materials storage areas. In large-scale infrastructure such as subway stations, airports, and tunnels, vertical pressure-surge tank systems, with their high reliability and low maintenance, provide a solid foundation for emergency firefighting. Furthermore, this system can serve as a secondary water supply and pressure-stabilizing device for locations with insufficient municipal water pressure, providing dual security for firefighting and domestic water supply. Overall, the vertical pressure-surge tank system, with its high stability, intelligent control, energy-saving operation, compact design, and excellent safety performance, has become an indispensable key component in modern fire water supply systems. It not only optimizes the overall operational efficiency of fire pipe networks, reducing energy consumption and maintenance frequency, but also ensures the immediacy and reliability of fire water supply at critical moments. With the continuous improvement of urban construction and industrial safety standards, this type of intelligent and integrated vertical pressure-surge tank system will become a key trend in the development of fire protection engineering, providing more efficient, intelligent, and sustainable solutions for global fire safety.