Stainless Steel Piping Design: Enhancing Durability and Hygiene in Fire Pump Systems

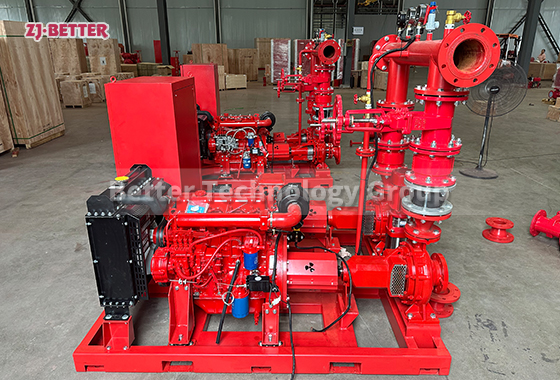

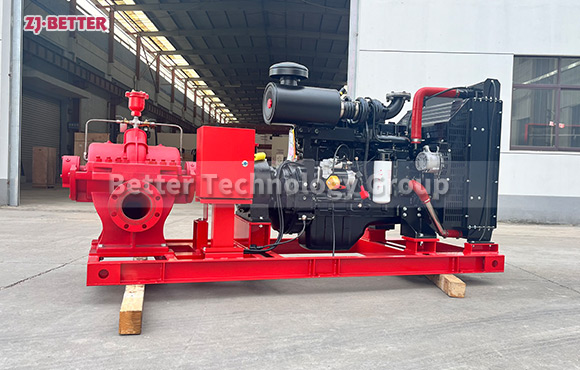

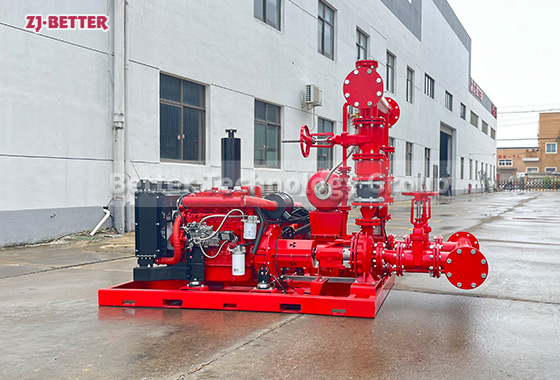

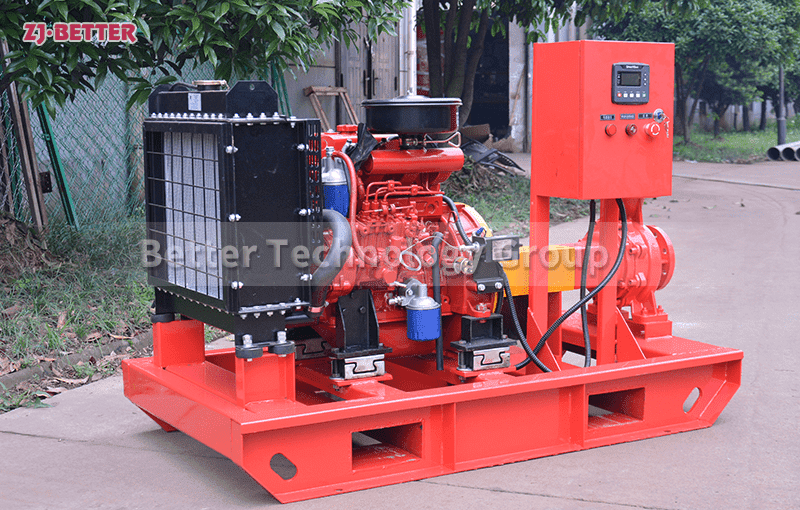

Stainless steel pipe fire pump units offer excellent corrosion resistance, strength, and sanitation, ensuring long-term stable water supply and clean water quality. Highly efficient and energy-efficient, they are easy to maintain and are widely used in high-end buildings, industrial sites, and public facilities, providing safe and reliable protection for fire protection systems.

In modern fire water supply systems, the design and material selection of the pump unit’s piping directly determine the equipment’s operational stability, service life, and water quality. Fire pump units with stainless steel piping, due to their high strength, corrosion resistance, and easy cleanability, are becoming a key industry trend. Compared to traditional carbon steel or galvanized pipes, stainless steel piping offers unparalleled advantages in durability and sanitation, making it particularly suitable for applications in buildings and industrial settings that require high water quality, long-term continuous operation, and high reliability. This design not only ensures stable operation in harsh environments but also effectively reduces maintenance costs, providing users with more efficient and safer water supply and fire protection. Firstly, in terms of durability, stainless steel is highly corrosion-resistant and resists rusting even in prolonged water contact, effectively preventing corrosion-related leaks, pipe blockages, and equipment damage. Long-term system stability is crucial for fire pump units, as any piping failure could compromise water supply efficiency and, in turn, reduce fire safety. The outstanding corrosion resistance of stainless steel piping enables the pump unit to maintain stable performance in high humidity, chloride-containing, or acidic and alkaline environments, significantly extending the overall service life of the equipment. Furthermore, the stainless steel piping design offers unique advantages in terms of hygiene. Due to its smooth surface, stainless steel is less susceptible to scale and bacterial growth. This ensures that fire water supply remains clean during transportation, preventing contamination from the pipes and potentially affecting water quality. This characteristic is particularly important in public buildings, hospitals, and high-end commercial complexes, which have stringent water quality requirements. In contrast, traditional pipes are prone to scale and impurity deposits over time, affecting water supply efficiency and increasing the difficulty of cleaning and maintenance. Stainless steel significantly reduces this risk, ensuring a higher standard of hygiene. Furthermore, the mechanical strength and structural stability of stainless steel piping also enhance the overall performance of the fire pump unit. Even under high pressure, the piping maintains minimal deformation, making it less susceptible to rupture or leakage. This is crucial for firefighting systems that require constant water pressure. In emergencies, fire pump units must quickly build and maintain sufficient water pressure to ensure effective firefighting. The pressure resistance and strength of stainless steel piping enable the system to operate stably under high-load conditions, providing a solid foundation for fire safety. Furthermore, stainless steel’s inherent high-temperature resistance allows it to maintain relatively stable physical properties even under the intense heat of a fire, further ensuring the system’s reliability in extreme environments. Stainless steel piping also offers significant convenience in installation and maintenance. Modern stainless steel piping systems typically utilize a standardized modular design, offering tight and leak-tight connections, reducing on-site welding and complex installation procedures. This not only shortens installation time but also reduces construction costs. During ongoing maintenance, stainless steel piping’s corrosion and wear resistance extend inspection cycles, significantly reducing routine maintenance workload. Even when system replacement or expansion is necessary, modular stainless steel piping allows for quick assembly and modification, greatly enhancing system flexibility and scalability. Energy efficiency and high efficiency are also key advantages of stainless steel-piped fire pump systems. The smooth inner wall reduces fluid resistance, minimizing frictional losses during water transport, thereby improving overall pump efficiency and reducing energy consumption. In long-term operation, this not only helps users reduce energy costs but also conforms to the trend of green energy conservation and meets the dual requirements of environmental protection and efficiency in modern buildings and industrial systems. Furthermore, fire pump sets with stainless steel piping offer advantages in appearance and craftsmanship. Stainless steel inherently possesses a fine metallic texture and luster, and after fine processing, it boasts a high overall aesthetic, further meeting the aesthetic and quality requirements of modern building mechanical and electrical equipment. For high-end venues where the quality of equipment must be showcased, this design undoubtedly elevates the overall project’s quality and image. Regarding reliability, stainless steel piping pump sets undergo rigorous testing and quality control to meet international fire standards and safety regulations. This high standard of quality assurance makes them suitable not only for conventional buildings and residential communities, but also for critical locations such as airports, subways, hospitals, commercial complexes, and factory workshops. In these locations, stable equipment operation is directly related to the safety of personnel and property, making fire pump sets with stainless steel piping an ideal choice. With the continuous advancement of intelligent and automated technologies, stainless steel piping fire pump sets are increasingly incorporating intelligent control systems, enabling functions such as automatic start and stop, pressure monitoring, and remote control. Combined with highly durable stainless steel pipes, the system can maintain stable operation for a long time without supervision, and provide real-time feedback of operating data through the remote monitoring platform, providing management personnel with a more scientific basis for maintenance and scheduling. The advantages of this combination of intelligence and high-quality materials further enhance the overall performance and use value of the system. In general, fire pump sets designed with stainless steel pipes have significant advantages in durability, hygienic performance, structural stability, installation convenience, energy-saving efficiency, and appearance craftsmanship. This design not only conforms to the development trend of modern fire-fighting equipment towards high quality, long life, and low maintenance, but also provides users with safer and more reliable fire protection. In future applications, as the requirements for building safety and water quality continue to increase, stainless steel pipe fire pump sets will be widely used in more fields and become an important part of high-standard fire protection systems.