Steady-Pressure Inline Fire Pump Meeting Multiple Fire Protection Requirements

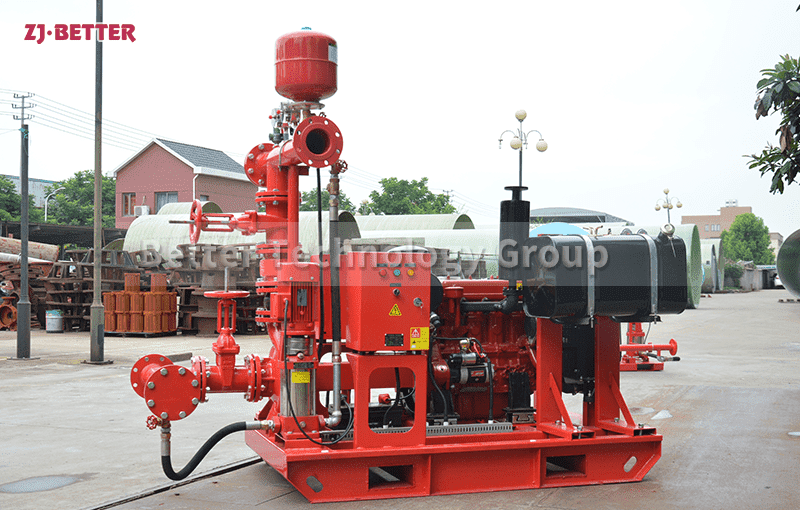

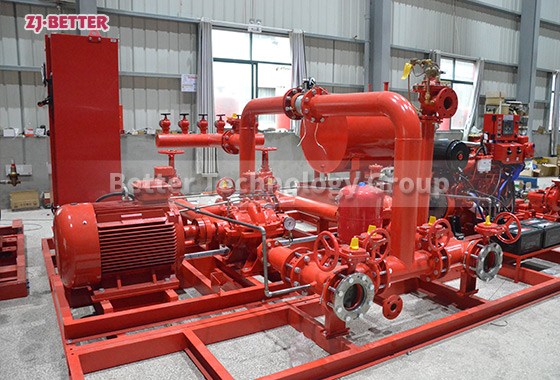

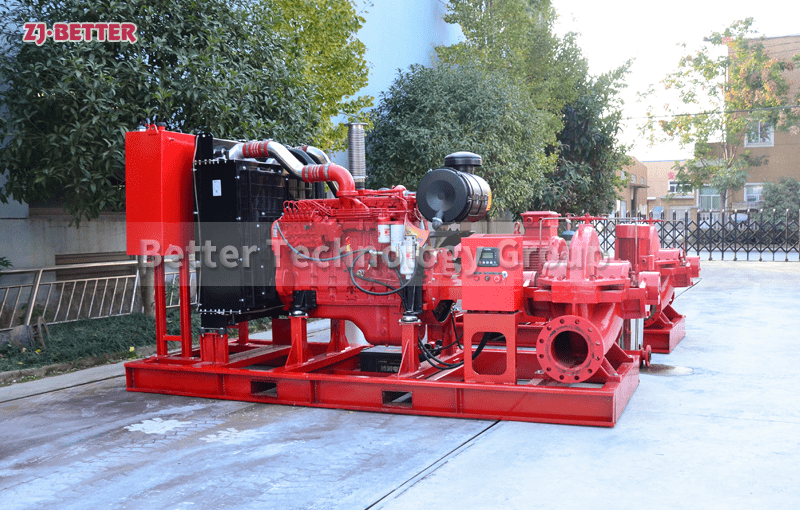

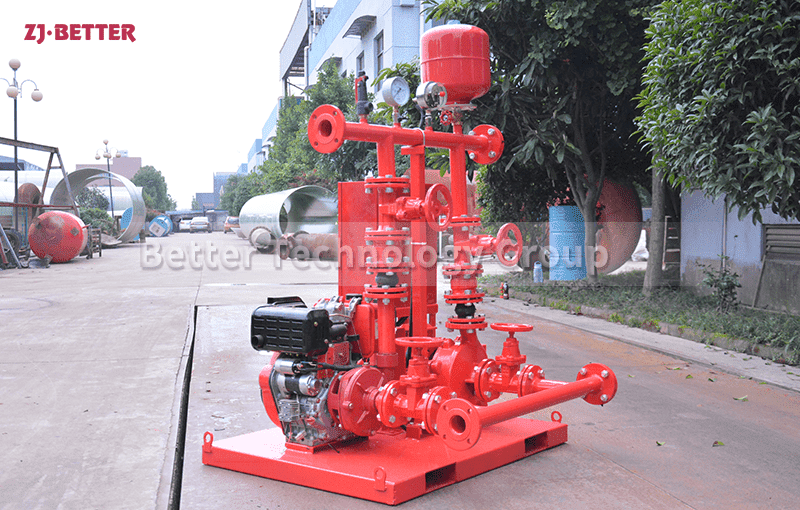

The inline centrifugal fire pump delivers stable pressure, compact structure, and high efficiency, ideal for fire water supply in high-rise buildings, industrial facilities, and municipal projects. With smooth operation, low noise, and easy maintenance, it ensures constant pressure and reliable performance for modern fire protection systems.

In modern building and industrial fire protection systems, the performance stability of fire pumps directly determines whether the system can effectively extinguish fires in critical moments. With increasingly complex building structures and ever-improving fire protection standards, ensuring continuous and stable water supply pressure has become a core design and manufacturing challenge. Pipeline centrifugal fire pumps are highly efficient devices developed in this context. With their stable pressure output, compact design, and excellent energy-saving performance, they are widely used in high-rise buildings, underground facilities, industrial parks, and municipal fire protection systems, becoming a key power source for ensuring stable fire water supply.

One of the most significant features of pipeline centrifugal fire pumps is their stable pressure output capability. In the event of a fire, the fire protection system needs to provide sufficient pressure and flow within a short time to ensure the simultaneous operation of sprinkler systems, fire hydrant systems, and water curtain systems. This pump achieves a perfect balance between high head and constant pressure through optimized hydraulic design and precise impeller matching. Even with simultaneous water intake at multiple points or fluctuations in pipe network resistance, it can maintain stable outlet pressure, avoiding uneven water spraying or delayed system response due to insufficient pressure. The pump body adopts a streamlined internal structure design, resulting in lower liquid flow resistance and lower energy loss, thus making the entire system operate more efficiently. Stable pressure output not only improves fire extinguishing efficiency but also ensures system reliability and response speed.

In terms of structural design, the pipeline centrifugal fire pump adopts a vertical installation method, with the inlet and outlet on the same horizontal line, allowing it to be directly installed into the system like a pipeline. This design greatly saves installation space, making it particularly suitable for locations with limited machine room area or compact piping layouts. The pump body has a compact overall structure, a centrally located center of gravity, stable operation, and low vibration, and can be directly connected to the piping network without additional supports. Compared with traditional horizontal fire pumps, vertical pipeline pumps not only occupy less space but also facilitate maintenance and daily management. Its vertical structure ensures balanced axial force, reduces mechanical wear, and extends equipment lifespan. Because the inlet and outlet water directions are consistent, there is no need to change the original pipeline routing during installation, significantly shortening the installation cycle, reducing construction costs, and providing users with a more flexible and efficient fire water supply solution.

In terms of performance, the pipeline centrifugal fire pump has two major advantages: high efficiency and strong adaptability. It adopts a high-precision dynamically balanced impeller and a low-hydraulic-loss pump casing design, which greatly improves energy conversion efficiency, resulting in higher pump efficiency and lower power consumption. The motor and pump body adopt an integrated direct-drive structure, reducing transmission losses and improving operational stability. All internal flow channels of the pump body are optimized and polished, effectively reducing water flow impact and noise, resulting in quieter and smoother operation. Under continuous operation, the motor temperature rise is low, demonstrating excellent cooling performance and enabling long-term trouble-free operation. It exhibits excellent adaptability and reliability in constant pressure water supply systems, fire backup systems, and emergency drainage systems.

The pipeline centrifugal fire pump also possesses good durability and corrosion resistance. Since fire water supply often involves year-round stored clean water or media containing slight impurities, the pump body and key components are made of high-strength cast iron or stainless steel, treated with anti-corrosion materials, exhibiting strong pressure resistance and a long service life. The shaft seal uses a high-temperature resistant and wear-resistant mechanical seal structure, ensuring good sealing performance and preventing leakage even under high pressure and high temperature environments. Imported, load-bearing bearings are selected, combined with a high-precision lubrication system, ensuring smooth operation even at high speeds. Multiple sealing and protection designs effectively enhance the reliability of the equipment in complex environments, enabling it to maintain stable operation for extended periods, even in environments with extreme temperature differences, high humidity, or high dust levels.

Regarding noise and vibration control, this series of fire pumps exhibits excellent quiet operation. Through dynamic balancing and precision machining, the concentricity of the motor rotor and impeller is extremely high, resulting in virtually no mechanical friction vibration during operation. Simultaneously, a shock-absorbing structure at the pump’s bottom effectively absorbs vibration energy generated during operation, reducing noise propagation. Compared to traditional pumps, its operating noise can be reduced by more than 30%, making it ideal for installation in underground machine rooms, commercial complexes, and office buildings with stringent noise control requirements. Low noise not only improves the equipment’s operating environment but also reduces fatigue damage to pipes and valves caused by vibration, thereby extending the overall system lifespan.

In terms of intelligent and automatic control, modern pipeline centrifugal fire pumps widely utilize electrical control and monitoring technologies. The pump can be linked with an automatic control system to achieve automatic start/stop, pressure sensing, and fault alarms. When the system detects a pressure drop or insufficient water flow, the pump automatically starts to replenish pressure; it automatically shuts down after the fire is extinguished, avoiding energy waste. The control cabinet is equipped with temperature sensors, current monitoring devices, and a remote communication module, enabling real-time feedback of equipment operating status and facilitating remote monitoring and data acquisition. Management personnel can monitor pump operation via a smart terminal, including parameters such as water pressure, flow rate, motor temperature, and energy consumption, thus enabling preventative maintenance and avoiding sudden malfunctions.

Energy saving is also a significant advantage of the pipeline centrifugal fire pump. By employing high-efficiency motors, optimized hydraulic models, and variable frequency control technology, the pump can automatically adjust its speed according to system requirements, maintaining constant pressure output while significantly reducing energy consumption. The variable frequency control system can automatically optimize the operating point under different loads, improving the energy efficiency ratio by 10% to 30%. In non-fire conditions, the system can operate in energy-saving standby mode, further reducing power consumption. This intelligent energy-saving design not only meets modern building energy efficiency standards but also helps reduce operating costs, achieving both economic and safety benefits.

In terms of installation and maintenance, the pipeline centrifugal fire pump offers significant convenience. Its modular design simplifies the installation process, allowing direct connection to existing pipe networks without complex foundation construction. During maintenance, only the upper part of the motor needs to be disassembled for shaft seal or impeller maintenance, eliminating the need to dismantle the entire unit and significantly reducing maintenance time. All connections use standard flange interfaces for easy replacement and maintenance. Furthermore, vent holes and drain outlets are pre-installed on the pump body for convenient daily maintenance and anti-freeze operations. The overall design fully considers user convenience for maintenance and long-term operational economy, reflecting the human-centered and intelligent trends in modern industrial equipment.

From an application perspective, pipeline centrifugal fire pumps are widely applicable to high-rise buildings, commercial centers, underground parking lots, hospitals, schools, factories, and municipal water supply projects. Whether used as a main pump or a standby pump, they provide continuous and stable pressure support in fire protection systems. In multi-pump parallel systems, they can automatically switch operation according to the needs of different floors or areas, achieving multi-stage water supply and pressure regulation. Their excellent stability and reliability make them an indispensable piece of equipment in fire protection systems. For locations requiring continuous water supply or emergency backup, the high performance, high efficiency, and high reliability of pipeline centrifugal fire pumps ensure that the fire protection system is always in optimal working condition.

In conclusion, the pipeline centrifugal fire pump with stable pressure output, with its comprehensive advantages such as high efficiency, stability, energy saving, quiet operation, and ease of maintenance, perfectly meets the fire safety needs of modern buildings and industrial facilities. It is not only a high-performance fire water supply device, but also represents the direction of fire protection systems towards intelligent and green development. With continuous improvements in manufacturing processes and the popularization of intelligent control technology, pipeline centrifugal fire pumps will continue to play an even more important role in the fire protection field, providing solid support for urban safety and life protection.