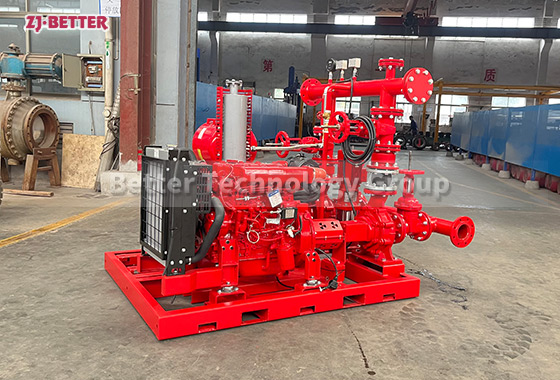

High Flow, Low Noise, Long Life – The Core Features of Modern Fire Pumps

The modern fire pump features high flow, low noise, and long service life with advanced hydraulic design and efficient motor performance. It delivers powerful water supply, quiet operation, and outstanding durability, ideal for fire protection systems in high-rise buildings, industrial facilities, and municipal projects.

In modern building fire protection systems, fire pumps, as the core water supply equipment, directly affect the system’s ability to function effectively in critical moments. With the continuous advancement of urbanization, building heights and structural complexity are increasing, leading to increasingly stringent performance requirements for fire protection equipment. High flow rate, low noise, and long lifespan have become important development directions for modern fire pumps. These three characteristics not only represent the manufacturing level of fire pumps but also reflect the modernization of building fire safety assurance. The high flow rate characteristic of fire pumps is crucial for ensuring fire extinguishing efficiency. Facing the multi-level and multi-space fire protection needs of high-rise buildings, underground projects, and industrial plants, fire pumps must provide sufficient water volume and pressure in a short time to meet the water requirements of sprinkler systems, fire hydrant systems, and other fire extinguishing facilities. High-flow-rate fire pumps employ advanced hydraulic design and optimized impeller structures, allowing for smoother liquid flow within the pump body, effectively reducing water flow resistance and increasing flow output. Their efficient hydraulic model enables a larger water output at the same power, significantly improving overall water delivery efficiency. Meanwhile, the pump body’s inner wall undergoes anti-corrosion and anti-rust treatment, ensuring stable performance even during long-term operation in fire-fighting water environments containing impurities. The high-flow design not only signifies powerful water delivery capacity but also guarantees sufficient pressure in emergencies, allowing the fire-fighting system to achieve maximum fire-extinguishing effect in a short time, thereby effectively reducing fire losses. Low noise performance is a crucial aspect of modern building equipment comfort requirements. Traditional fire pumps often generate significant noise during operation due to mechanical friction, water flow impact, and motor vibration, affecting the machine room environment and surrounding areas. The low-noise fire pump significantly reduces mechanical and fluid noise through the use of high-precision dynamic balancing technology, optimized pump body flow channel design, and high-quality bearings and sealing systems. The motor section employs a high-efficiency, quiet design with higher rotor balance and minimal vibration during operation. The connection between the base and pump body utilizes a shock-absorbing pad structure to effectively absorb mechanical vibration during operation, ensuring stable operation even under high loads. This low-noise characteristic not only improves the comfort of the working environment but also extends the service life of the pump body and piping system, preventing component fatigue or loosening of connections caused by vibration and noise, thus providing a more durable and stable operating foundation for the fire protection system. Long-life design is the core advantage of fire pumps for long-term stable operation. Most fire-fighting equipment is in standby mode, but once activated, it must operate reliably, requiring pumps with extremely high durability and fatigue resistance. Modern fire pumps are manufactured using high-strength cast iron or ductile iron materials, and the impeller undergoes precision machining and dynamic balancing to ensure no deformation or wear during long-term operation. The shaft sealing system uses high-temperature and corrosion-resistant mechanical seals to effectively prevent leakage and extend equipment life. Bearings are wear-resistant and high-load-bearing models, coupled with an automatic lubrication system to reduce maintenance frequency. The motor uses high-grade insulation materials and a high-efficiency cooling structure, enabling stable operation in high-temperature environments without affecting performance. All key components undergo rigorous factory testing to ensure good reliability even under extreme operating conditions. The long lifespan of fire pumps not only means reduced maintenance costs but also ensures the normal operation of the fire protection system in critical moments, avoiding system failures caused by equipment aging. Beyond these three core features, modern fire pumps have also made significant progress in intelligence and energy conservation. With the development of building automation systems, fire pumps can be linked with fire control centers, possessing intelligent functions such as automatic start/stop, pressure monitoring, and flow regulation. When the system detects a pressure drop, the pump automatically starts to replenish water pressure; after the fire is extinguished, it automatically stops operating, avoiding energy waste. The pump’s control system uses high-precision sensors and intelligent modules to monitor motor temperature, bearing status, and water flow parameters in real time, feeding the data back to the monitoring system for early warning and remote maintenance. This intelligent design not only improves system safety and response speed but also greatly reduces the cost of manual inspections. Energy efficiency is also a crucial aspect of fire pump design. By optimizing the hydraulic structure, improving motor efficiency, and adopting variable frequency control technology, fire pumps can automatically adjust speed and flow according to system requirements, thereby significantly reducing energy consumption while ensuring fire protection performance. In non-fire conditions, the system can operate in standby or low-speed mode, effectively extending the service life of the motor and bearings. This energy-saving operating mode aligns with the modern trend of green and energy-efficient building development, providing users with an economical and environmentally friendly fire protection solution. Fire pumps have a wide range of applications, covering high-rise buildings, industrial parks, underground parking garages, warehousing and logistics centers, airports, docks, and municipal facilities. While the performance requirements for fire pumps vary slightly depending on the location, a common thread is the high importance placed on stability and reliability. In high-rise buildings, fire pumps need to overcome the challenge of high-lift water supply to ensure sufficient water pressure on every floor. In industrial plants, high flow rate and corrosion resistance are paramount to cope with complex environments involving high temperatures, dust, or chemical media. In underground facilities, low noise and moisture-proof design are crucial to ensure a safe and quiet environment for long-term operation. As a vital component of building safety systems, the technological advancement of fire pumps is not only reflected in the optimization of individual performance parameters but also in the reliable coordination and stable operation of the entire system. High flow rate signifies strong water supply capacity, low noise reflects the precision manufacturing level of the equipment, and long lifespan represents a combination of durability and economy. These three factors together constitute the core competitiveness of modern fire pumps. In the future, with the further development of intelligent manufacturing and IoT technologies, fire pumps will become more intelligent, modular, and efficient. It will no longer be just a mechanical device, but an intelligent terminal integrated into a smart fire protection system, capable of real-time response, automatic adjustment, and precise water supply. Through continuous technological innovation and structural optimization, modern fire pumps will play an increasingly important role in ensuring urban fire safety, improving emergency response efficiency, and promoting green building development. Whether in large industrial bases or high-rise commercial complexes, choosing a high-flow, low-noise, and long-life fire pump is key to improving the safety and reliability of fire protection systems.