From Auto-Control to Stable Supply: Advancing Intelligent Fire Management with Electric Fire Pumps

Electric fire pump units feature intelligent auto-control, stable water supply, multi-layer safety protection, and energy efficiency. Widely used in high-rise buildings, commercial complexes, and industrial facilities, these integrated systems are easy to install, remotely manageable, and ideal for smart fire protection solutions.

With the rapid development of urban construction, the demand for efficient and intelligent fire protection systems is increasing. Traditional manual firefighting methods and outdated pump equipment are no longer sufficient. Electric fire pump units, with their smart control, stable operation, and reliable water supply capabilities, have become essential components of modern fire safety solutions. This article explores the key advantages and strategic value of electric fire pump systems in smart fire management.

1. Smart Auto-Control for Rapid Emergency Response

Equipped with intelligent control systems, electric fire pumps can automatically start and stop based on pipeline pressure or fire alarm signals. The system can respond within seconds, delivering water for firefighting immediately. This automation greatly improves emergency response time and enhances fire suppression efficiency.

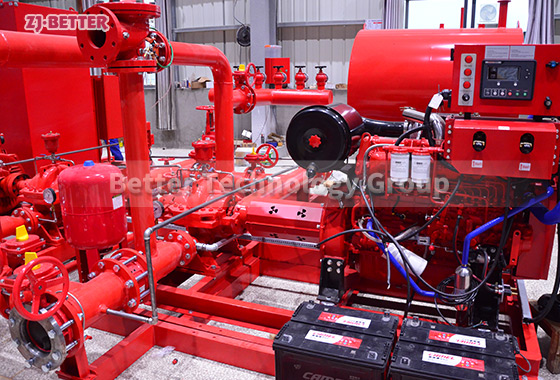

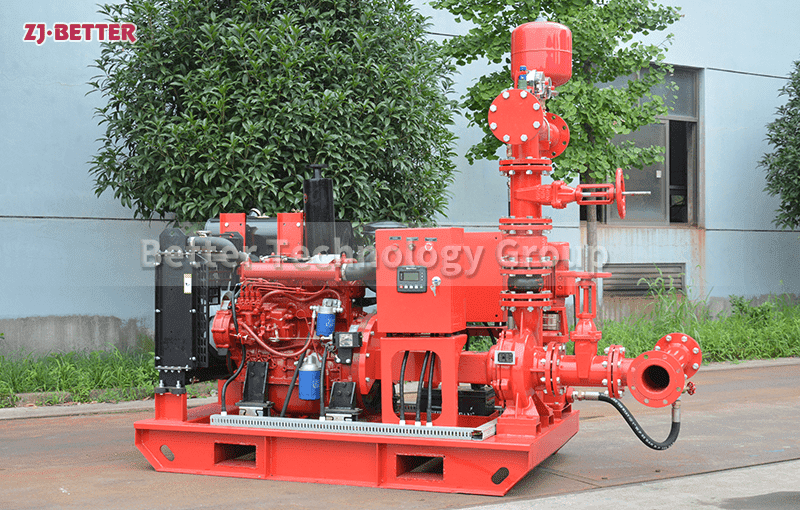

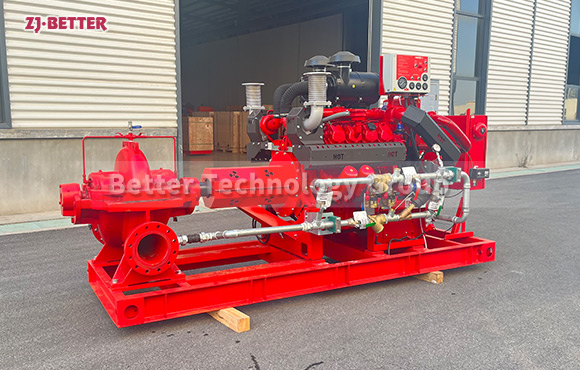

2. Integrated Modular Design for Easy Installation and Maintenance

The pump unit is a compact, integrated solution that combines the motor, control cabinet, booster system, and main pump. Installation only requires basic water and power connections, minimizing construction time. The well-structured layout also makes routine maintenance more efficient and cost-effective.

3. Reliable and Stable Water Supply

The system works with pressure stabilizers and jockey pumps to maintain constant water pressure, even under demanding conditions. This ensures uninterrupted water delivery during emergencies, which is crucial for high-rise buildings, industrial plants, and large commercial centers.

4. Multiple Safety Protections for Secure Operation

With built-in protection against overpressure, under-voltage, overload, phase loss, and short-circuit, the system continuously monitors its operational status. It triggers automatic shutdown and alarms in case of anomalies, reducing risk and safeguarding both personnel and property.

5. Energy-Saving and Eco-Friendly Operation

Thanks to high-efficiency motors and intelligent energy management, the pump adjusts operation according to water demand. It significantly reduces energy waste, runs quietly, and emits no exhaust, making it an ideal choice for green and sustainable buildings.

6. Flexible Configuration for Diverse Applications

This system is suitable for various environments, including residential buildings, hospitals, schools, factories, and logistics centers. Whether configured as a single-pump or multi-pump system, it can be customized to meet different engineering requirements.

7. Remote Monitoring and Smart Data Management

Advanced models offer cloud-based remote monitoring. Operators can access real-time operational data from mobile devices or PCs. Alarm notifications, performance records, and data logs support proactive maintenance and improve system reliability.

8. Superior Manufacturing for Long-Term Reliability

Constructed with premium materials and manufactured under strict quality control, every component is thoroughly tested. Anti-corrosion coatings and robust assembly processes ensure long-term performance, even in harsh environments.

9. Full Technical Support for Hassle-Free Operation

From pre-sale consultation and design to installation, training, and after-sales service, manufacturers provide end-to-end technical support, ensuring the pump system operates smoothly throughout its lifecycle.

10. Enhance Project Value and Fire Code Compliance

The system meets national fire safety standards and helps projects pass inspection and approval efficiently. Its high reliability boosts the overall safety rating of facilities and enhances the commercial value of the project.

Electric fire pump units are at the forefront of smart fire safety systems. With their automation, stable performance, and eco-friendly design, they play a critical role in protecting lives and property. Investing in a high-quality electric fire pump is not just a safety measure—it’s a forward-looking decision that ensures long-term value and peace of mind.