How to Choose the Best Fire Pump Manufacturer

Discover essential tips for selecting the best fire pump manufacturer, focusing on quality, compliance, and reliability for your fire protection system.

Choosing the right fire pump manufacturer is crucial to ensuring the safety and efficiency of your fire protection system. A high-quality fire pump ensures reliable performance during emergencies, meets required standards, and reduces long-term maintenance costs. With numerous manufacturers in the market, it’s important to consider several factors to make an informed decision.

Here are key aspects to look for when selecting a fire pump manufacturer.

1. Compliance with Industry Standards

The first and most important factor is whether the manufacturer’s products comply with industry standards. Compliance ensures that the fire pumps meet the performance, safety, and reliability requirements outlined by regulatory bodies. Look for manufacturers who adhere to:

-

NFPA 20: This standard governs the installation of fire pumps and sets requirements for their performance, maintenance, and testing.

-

UL Listing: UL-listed fire pumps are tested for quality and safety. Ensure the manufacturer offers UL-certified pumps for your system.

-

ISO Certifications: Manufacturers with ISO certifications demonstrate a commitment to quality control and consistent production standards.

Make sure the fire pumps you choose are compliant with local regulations and have the necessary certifications to guarantee reliable performance during emergencies.

2. Quality and Reliability of Products

Quality is paramount when selecting a fire pump manufacturer. You want a product that will work effectively under pressure, especially during an emergency. Key indicators of quality include:

-

Durability: High-quality materials like stainless steel and corrosion-resistant components are essential for ensuring the longevity of fire pumps.

-

Testing: The manufacturer should conduct rigorous testing of their pumps to ensure they meet performance expectations.

-

Warranty: A reliable warranty indicates that the manufacturer is confident in the quality of their products and will support customers in case of defects or performance issues.

Before purchasing, inquire about the manufacturer’s quality assurance processes and check reviews or testimonials from other customers.

3. Customization and Sizing Options

A reputable fire pump manufacturer should offer a range of customization options to suit your specific needs. Depending on the building’s size, layout, and risk factors, you may require different types of pumps, such as:

-

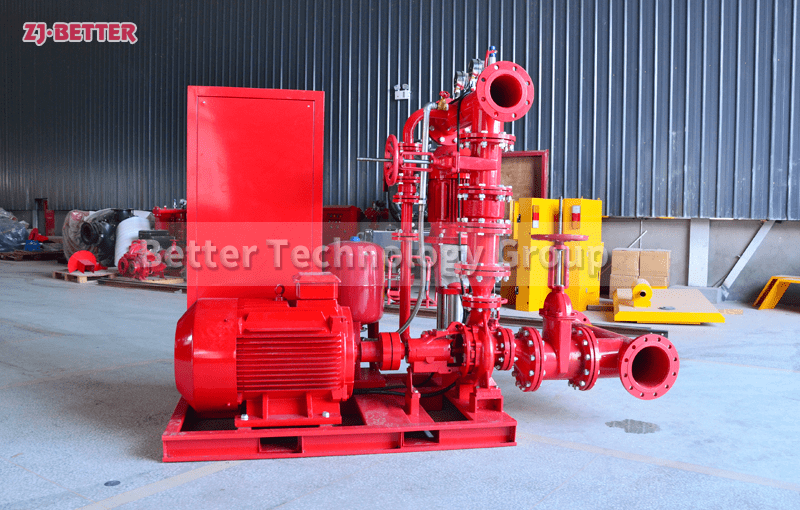

Electric fire pumps

-

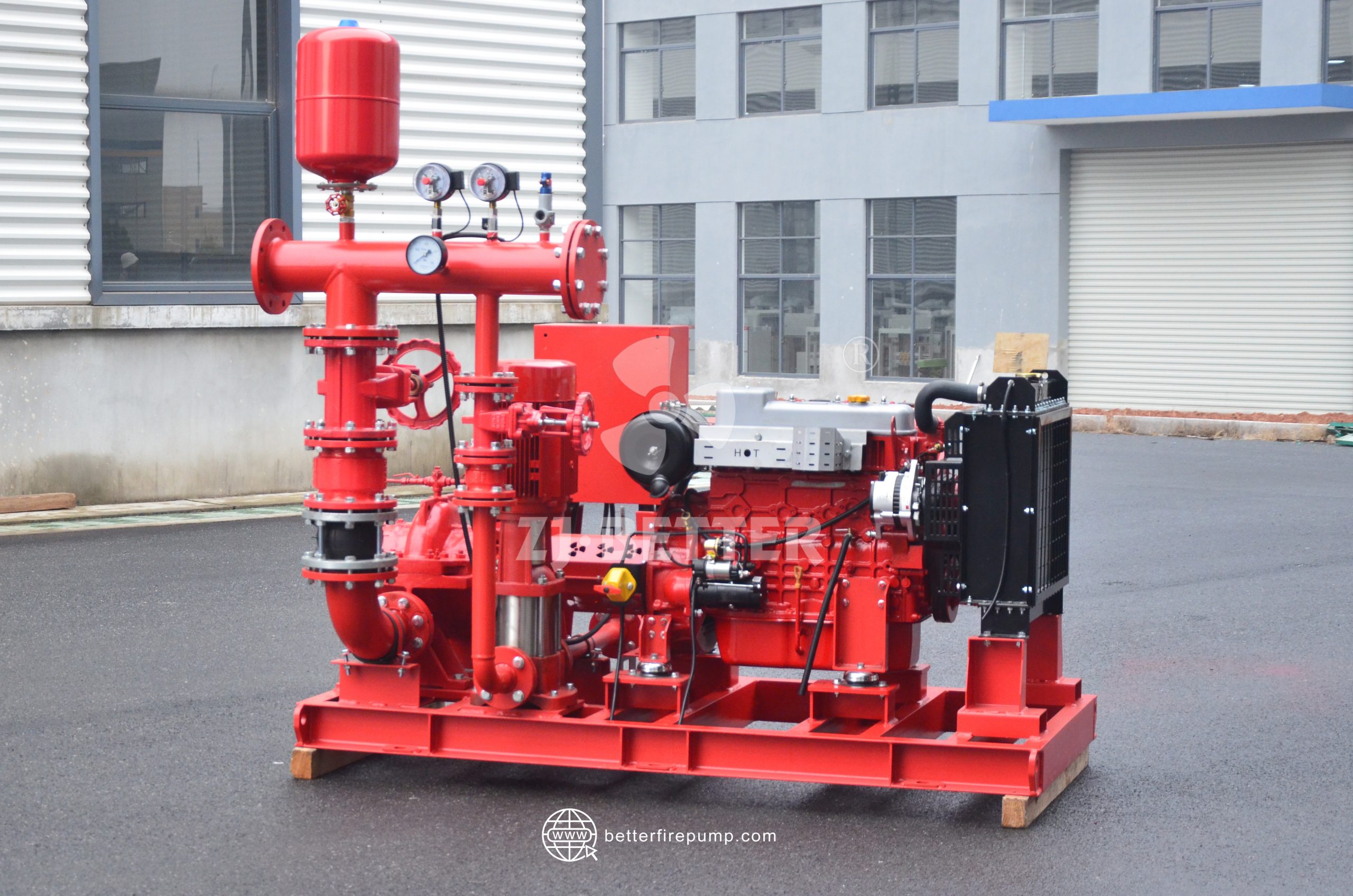

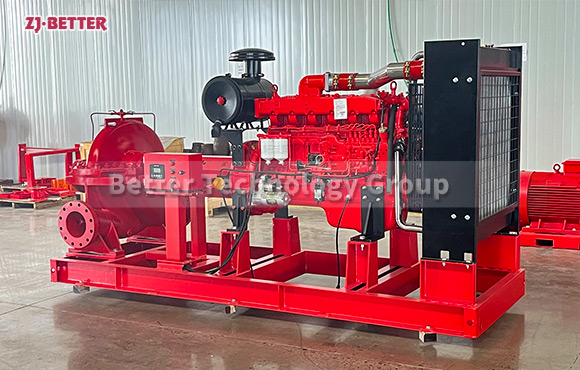

Diesel engine fire pumps

-

Jockey pumps

-

Vertical turbine pumps

Look for a manufacturer that provides consultation services to help you select the correct size and type of pump for your fire protection system. They should be able to guide you through the process of choosing the right pump based on flow requirements, pressure, and other unique factors specific to your building.

4. Experience and Reputation in the Industry

A manufacturer’s experience and reputation can provide valuable insight into the quality of their products and services. Established manufacturers with decades of experience are likely to have refined their processes and produced high-quality products that meet various needs. Consider the following when assessing their reputation:

-

Years in business: Manufacturers with a long track record in the industry are more likely to offer products that have been tested and proven over time.

-

Client portfolio: Check for testimonials or case studies of past projects. A manufacturer who has worked with large-scale or complex installations demonstrates the ability to handle diverse customer needs.

-

Industry involvement: Manufacturers who are actively involved in the fire protection industry, such as participating in trade associations or contributing to safety standards, are often committed to staying current with industry trends.

5. After-Sales Support and Service

Reliable after-sales support is critical for maintaining the longevity and performance of your fire pump. A manufacturer should offer comprehensive service options, including:

-

Installation services: Assistance with proper installation ensures that the system is up and running without issues.

-

Maintenance and repair services: Ensure the manufacturer has a dedicated team to provide regular maintenance, troubleshoot, and repair any issues with your fire pump system.

-

Spare parts availability: A good manufacturer will have spare parts readily available in case of wear or damage, reducing downtime for your fire protection system.

6. Cost and Value for Money

While price is always an important consideration, it should not be the sole deciding factor. Choosing a manufacturer based solely on price could lead to compromises in quality and reliability. Instead, consider the overall value for money, which includes the cost of the product, the quality of materials, the level of service provided, and the expected lifespan of the pump.

Remember that investing in a high-quality fire pump system upfront can save you money on repairs, maintenance, and replacements in the long run.

7. Global Reach and Availability

If you are managing multiple buildings across different regions or countries, it’s important to choose a fire pump manufacturer with a global presence. A manufacturer with a network of dealers or service providers can offer support, parts, and maintenance services no matter where your properties are located. Look for:

-

Local distributors and service centers

-

International shipping and installation options

-

Global compliance with regulations

Having access to local service providers can make ongoing maintenance and emergency repairs faster and more convenient.

Conclusion

Choosing the right fire pump manufacturer is essential to the safety and reliability of your fire protection system. Prioritize manufacturers that offer products compliant with industry standards, provide high-quality and durable equipment, and offer robust after-sales support. By taking the time to evaluate these factors, you can ensure your fire pump system is built to last and perform when needed most.