Top Emergency Water Supply Power: Detailed Overview of ZJ-Better Fire Pump Diesel Engine

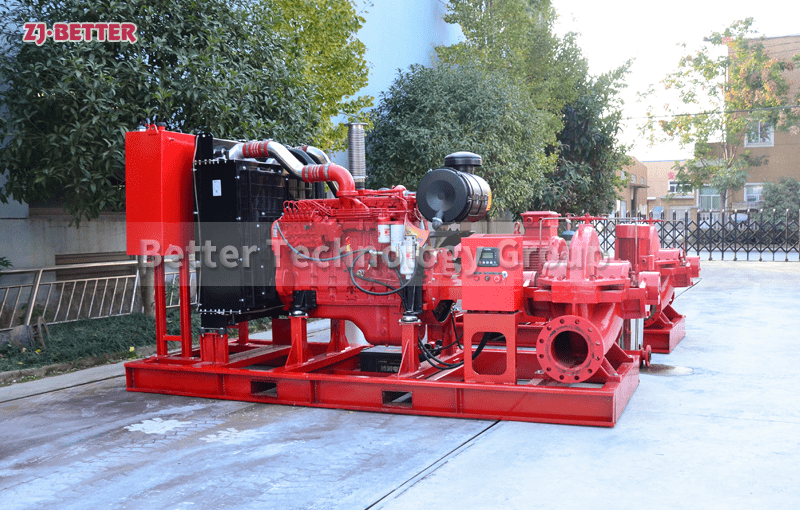

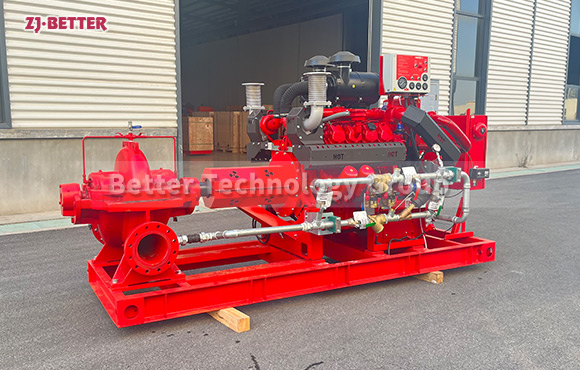

Explore the ZJ-Better Diesel Engine for Fire Pumps — a compact, high-efficiency power unit designed for emergency water supply systems. Featuring strong performance, fast startup, low fuel consumption, and reliable operation in extreme environments. Ideal for firefighting systems in buildings, factories, and remote areas.

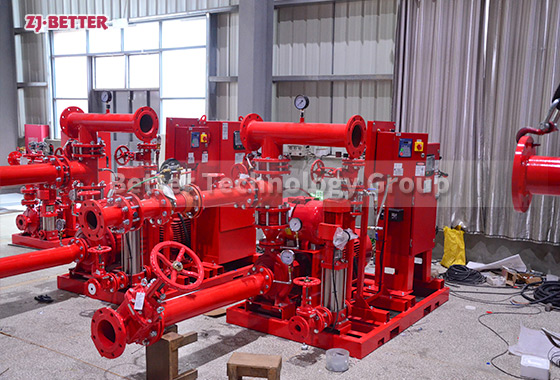

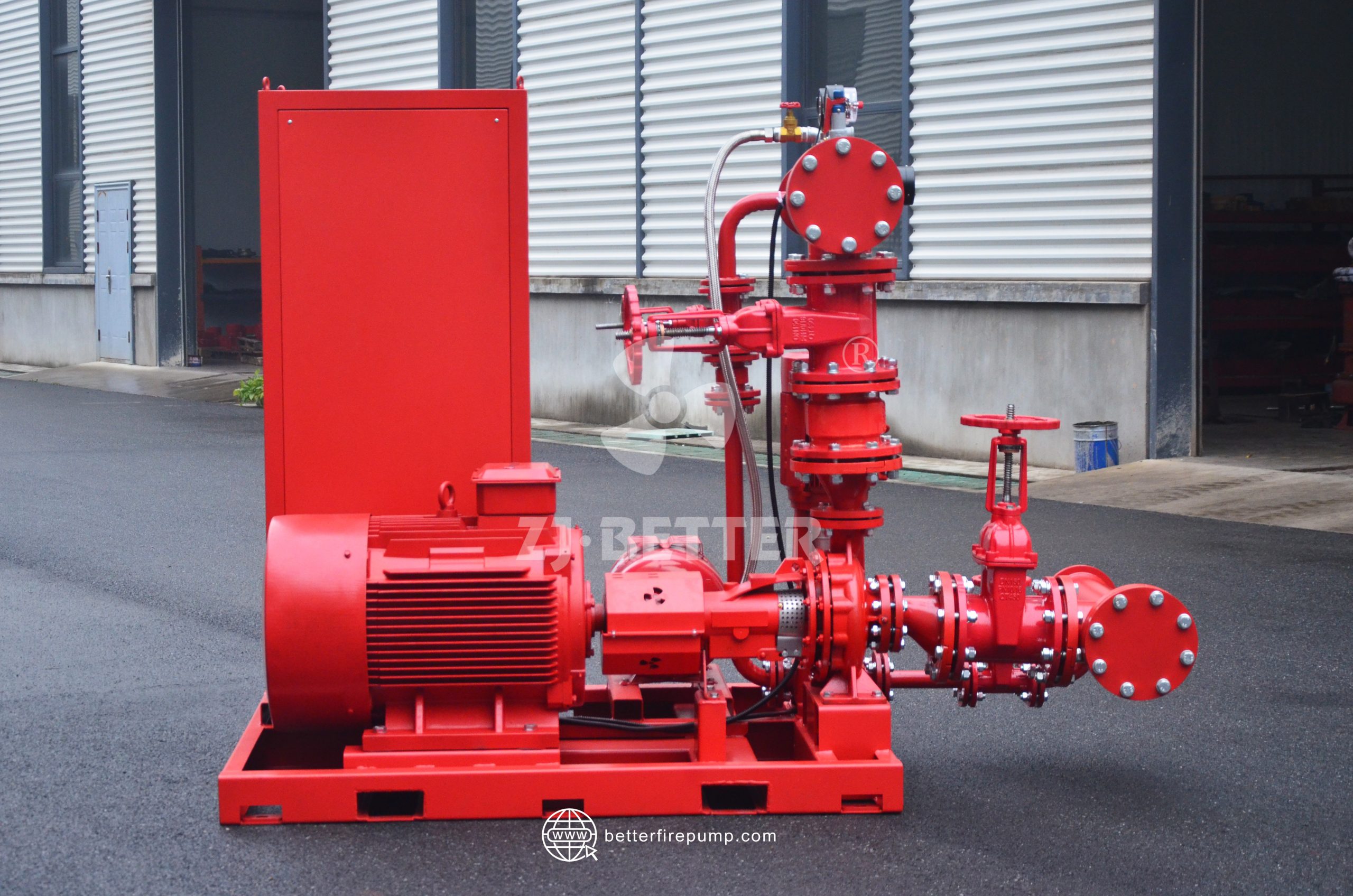

The ZJ-Better fire pump-matched diesel engine is a core component that provides power assurance for emergency water supply and firefighting systems, playing an indispensable role in modern firefighting systems. As the power source for fire pump systems, the performance of diesel engines directly determines the response speed, stability, and reliability of the entire system during critical moments. The ZJ-Better diesel engine is selected for its high-performance industrial-grade specifications, featuring rapid startup, low fuel consumption, and stable power output. It can maintain continuous operation without stalling even under extreme conditions, effectively meeting various emergency water supply tasks. The diesel engine adopts an advanced combustion system design, achieving excellent fuel atomization and more complete combustion, resulting in high overall thermal efficiency. This generates more energy per unit of fuel, reducing operational costs while minimizing exhaust emissions, making it more environmentally friendly. The ZJ-Better diesel engine has a compact structural design with a small footprint, making it easy to integrate with various types of fire pumps. It is particularly suitable for installation in space-constrained environments such as high-rise buildings, underground pump rooms, or mobile fire trucks. Its highly modular design facilitates routine maintenance and component replacement, significantly reducing downtime for maintenance and thereby enhancing the overall operational efficiency of the equipment. To enhance adaptability in harsh environments, the ZJ-Better diesel engine undergoes special anti-corrosion and anti-rust treatment, with a high-adhesion industrial-grade baked paint coating on the surface. This coating is resistant to moisture, oil contamination, or dust, ensuring stable performance. The engine is also designed to operate within a wide temperature range of -15°C to 50°C, enabling reliable startup and operation in extremely cold or hot regions. Its electronic control system features an intelligent control panel with built-in automatic start/stop functionality and a fault self-diagnosis system. In cases of low pressure, water shortage, or abnormal voltage, it can quickly issue an alarm and take corrective measures, effectively preventing fault escalation and ensuring the safety of personnel and equipment. Additionally, the ZJ-Better diesel engine has been specially optimized with a vibration control system and noise suppression structure. Through the rational arrangement of vibration-damping mounts, noise-reducing partitions, and fluid dynamics-optimized intake and exhaust channels, operational noise is kept within reasonable limits, making it particularly suitable for applications requiring low noise standards, such as residential areas, hospitals, and schools. The engine is compatible with multiple power output ranges, with common output ranges spanning from 15HP to 150HP, accommodating various flow rates and head requirements for fire pump applications. It also supports flexible coupling with various pump types, including centrifugal pumps, multistage pumps, end-suction pumps, and vertical pumps, enabling true “one engine for multiple uses,” facilitating customized selection based on actual engineering requirements. ZJ-Better strictly adheres to the ISO 9001 quality management system and NFPA 20 international fire safety standards for production and factory testing. All diesel engines must pass power tests, cold start tests, thermal stability tests, and high-load continuous operation tests to ensure they possess rapid startup and efficient water supply capabilities in real-world operational environments. Additionally, each engine is shipped with complete technical documentation, operating instructions, and maintenance manuals to facilitate post-delivery maintenance and servicing. In practical applications, ZJ-Better diesel engines are widely used in large-scale fire protection projects such as urban fire stations, high-rise buildings, airports, petrochemical bases, power plants, and port terminals. They have played a critical role in key engineering projects across multiple countries. Especially in regions with unstable power supply or high risk of power outages, diesel engine-driven fire pump systems have become a key solution to ensure the reliable startup of fire protection systems. Their emergency water supply capability not only addresses sudden fires but is also suitable for on-site rescue in various emergency situations such as water supply system failures and earthquakes. ZJ-Better is committed to providing customers with comprehensive fire protection system solutions. Its diesel engine series leads the industry in terms of quality stability, power response speed, installation flexibility, and service life. Combined with the company’s technical support and after-sales service, this effectively lowers user barriers and enhances system operational safety. Based on feedback from global customers, ZJ-Better diesel engines have received high praise in Africa, Southeast Asia, the Middle East, and Latin America, particularly for their reliability in high-temperature, high-humidity, and high-altitude regions, which fully demonstrates their outstanding manufacturing工艺 and engineering adaptability. In summary, the ZJ-Better fire pump-matched diesel engine, with its high energy efficiency, strong power, stability, durability, and strong adaptability, is not only an indispensable power hub for modern fire protection systems but also a core pillar ensuring emergency water supply safety. It is a reliable choice for customers seeking to build professional, efficient, and reliable fire protection systems.