Modular Fire Pressure Pump Station: Small Footprint, Easy Maintenance, Stable Operation

Compact modular fire pressure boosting station with stainless steel multistage pumps and intelligent control system. Designed for high-rise buildings, parking garages, and commercial facilities, it offers constant pressure supply, energy efficiency, easy installation, and 24/7 automated operation for stable and reliable fire protection.

Modern firefighting systems increasingly demand higher space efficiency, intelligent operation, and reliable performance. To meet these requirements, our modular fire pressure pump station offers a compact and integrated solution that maintains constant water pressure and ensures rapid system activation in emergency situations.

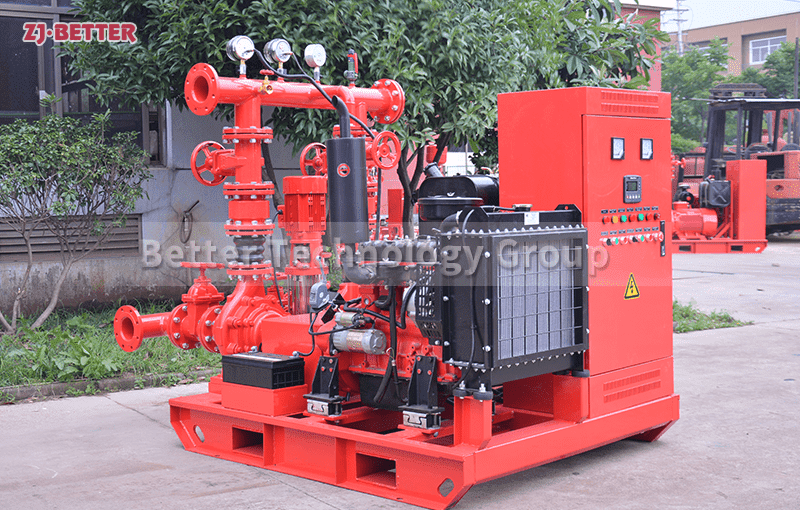

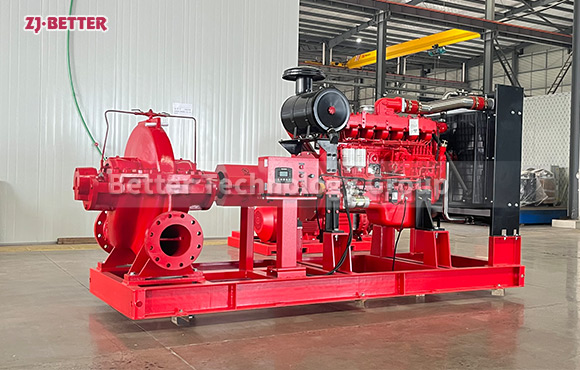

System Structure and Configuration

This modular unit consists of a stainless steel multistage centrifugal pump, intelligent control panel, pressure sensor array, pressure stabilization tank, and a robust integrated base frame. The components are strategically arranged for optimal space saving and performance. The control system supports remote monitoring, auto-start/stop, fault alarms, and overpressure/undervoltage protection to ensure long-term reliability.

Key Product Advantages:

-

Compact Footprint with High Integration

All components including the pump, piping, and control system are integrated into one base platform, minimizing space usage. Ideal for tight spaces like basements or utility rooms. -

High Efficiency and Energy Saving

Equipped with high-efficiency multistage stainless steel pumps, the system ensures smooth hydraulic performance and accurate pressure regulation. Automatically adjusts based on demand to reduce energy consumption. -

Simple Maintenance and Low Operational Cost

Quick-connect fittings and modular design allow for easy disassembly and repair. The smart controller enables remote fault diagnosis and maintenance alerts, minimizing downtime and labor costs. -

Smart Control for Instant Response

The system’s intelligent logic controller ensures accurate pressure maintenance and fast pump activation in case of pressure drop, enhancing system responsiveness and stability. -

High Reliability and Wide Environmental Adaptability

The unit is IP55 rated and suitable for harsh conditions including heat and humidity. All components are industrial-grade, making the system perfect for public, commercial, or industrial firefighting applications. -

Fully Automated Operation – 24/7 Protection

Configurable for 24/7 unattended operation with features like dry-run protection, low water level alarm, and automatic power switchover. A true plug-and-play safety system. -

Easy Installation with Broad Compatibility

Factory pre-assembled and tested before delivery. On-site setup requires only electrical and water inlet/outlet connection, making it ideal for both new installations and retrofit upgrades.

Application Scenarios:

This modular fire pressure boosting station is widely used in high-rise buildings, underground garages, commercial complexes, hospitals, industrial plants, and logistics warehouses, providing safe, efficient, and reliable firefighting water pressure support.