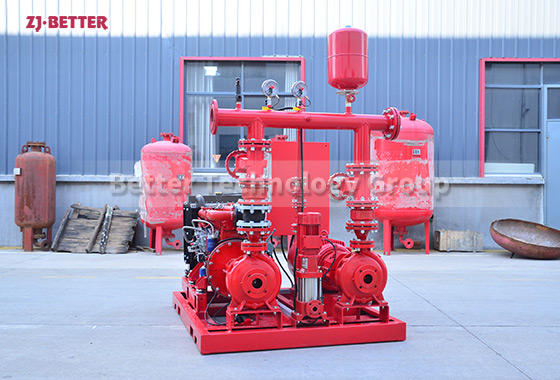

Multifunctional Diesel Fire Pump Set for High-Rise Buildings, Warehouses, and Petrochemical Facilities

Multifunctional diesel fire pump set designed for high-rise buildings, large warehouses, and petrochemical sites, featuring high head, large flow, smart control, and reliable water supply.

The multifunctional diesel fire pump set is a core equipment that provides stable fire water supply for high-risk building sites. It is particularly suitable for high-rise buildings, large storage centers and petrochemical special industrial environments. Such places have extremely high requirements for the reliability and response speed of the fire protection system, and the diesel-driven fire pump set has become an ideal choice for dealing with complex fire scenes with its significant advantages such as independence, durability, strong power output and intelligent control system. The diesel fire pump set is mainly composed of a diesel engine, a fire water pump, a cooling system, a control cabinet, a fuel tank, a basic base, a coupling and an instrumentation system, and has excellent performance stability and adaptability. Compared with electric fire pumps, diesel engine drive performs better in places where power is interrupted or insufficient, and can ensure continuous water supply at critical moments. It is an indispensable part of modern high-demand buildings and industrial projects.

In high-rise buildings, due to the high lift demand caused by the height of the floors, the fire protection system needs to have a strong water delivery capacity. The diesel fire pump set is driven by a high-power diesel engine, combined with a water pump with a high lift design, which can ensure that the water pressure is still maintained in a building with dozens of floors, and the fire water is delivered to the top floor without attenuation. At the same time, the multi-stage centrifugal pump structure equipped with the equipment greatly improves the stability of the head and flow rate on the basis of ensuring high efficiency, which not only improves the fire extinguishing efficiency, but also ensures that the nozzles at the end of each floor can be opened normally. For large-scale storage and logistics centers that require high-flow water supply, especially places where flammable materials are stored, diesel fire pump sets can continuously provide large-capacity water flow, quickly extinguish initial fires, and effectively reduce property losses.

In petrochemical environments such as petrochemicals, gas stations, and refineries, firefighting equipment must also meet strict standards such as explosion-proof, corrosion-resistant, and long-term operation. Diesel fire pump sets usually use explosion-proof control systems and anti-corrosion treated materials. The pump body and pipelines are coated with anti-corrosion coatings or made of stainless steel, which are suitable for conveying mildly corrosive liquids. In order to avoid failures caused by long-term high temperature and high-load operation, the pump set is equipped with an efficient cooling system, including air-cooled or water-cooled coolers, to ensure that the engine operates within a safe temperature range, thereby improving the equipment’s operating life and reliability. In addition, the pump set is equipped with a fuel system with an alarm system to ensure long-term uninterrupted oil supply and avoid system shutdown due to oil depletion, which greatly improves the equipment’s emergency continuous working capacity.

The degree of automation of the equipment is also one of its advantages. Equipped with an advanced intelligent control panel, it can realize multiple functions such as automatic start, pressure sensing start and stop, and remote control. Once the fire alarm system detects a drop in pressure, the pump group can automatically start within 5 to 15 seconds without manual intervention, saving critical response time. The control panel also has fault self-checking and real-time monitoring functions, which can record the operating status and give timely alarm prompts. Problems such as insufficient oil pressure, excessive water temperature, and start failure can be automatically identified and handled by alarm. This intelligent design not only improves the ease of use of the equipment, but also enhances the visualization and controllability of the system operation, which is convenient for maintenance personnel to conduct daily inspections.

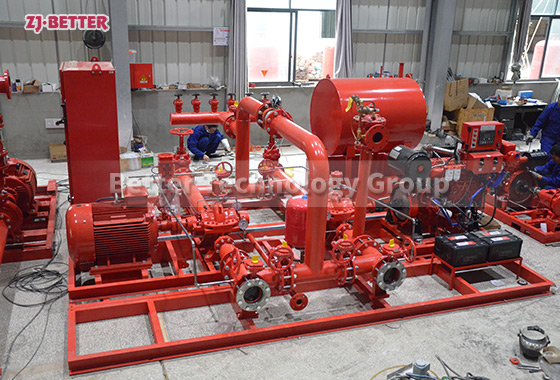

From the perspective of structural design, most diesel fire pump groups adopt an overall skid-mounted design, that is, all key components are installed on an integrated base, which is convenient for transportation, hoisting and on-site layout. Some models also have mobile functions, such as adding tires or trailer devices, so that the equipment has good flexibility when working in the field. The base adopts a thickened channel steel structure with strong load-bearing capacity and good shock absorption effect to prevent loosening and displacement due to vibration during startup or operation. The overall structure is compact and occupies a small area, which is suitable for deployment in places with limited space. In addition, the pump set undergoes strict tests before leaving the factory, including start-up test, pressure test, oil leakage test, etc., to ensure that it can be installed and used immediately after arriving at the user’s site.

In terms of maintenance, the diesel fire pump set also reflects the advantages of humanized design. All maintenance points are reasonably arranged to facilitate technicians to inspect and maintain. The oil filter, air filter, coolant filling port, battery inspection port, etc. are all set on one side of the operating surface, and daily maintenance work can be completed without removing a large amount of shell. At the same time, the equipment comes with operating instructions and maintenance manuals, and with on-site markings, novice operators can also master basic operation and maintenance methods in a short time. For places with low frequency of use, the system can also set an automatic weekly test operation function to avoid starting difficulties or component corrosion due to long-term non-starting.

In terms of energy efficiency, modern diesel fire pump sets use high-efficiency fuel injection systems and low-emission engines, which are more energy-saving and environmentally friendly. Advanced fuel injection technology improves combustion efficiency and reduces fuel consumption; with reasonable air-fuel ratio control and low-noise muffler, the equipment is energy-saving and quiet during operation, meeting the requirements of urban buildings for environmental protection and noise control. Some pump sets are also equipped with low-temperature preheating devices, so that the equipment can start quickly even in sub-zero low-temperature environments, which is suitable for projects with complex climates such as cold areas in the north, mountainous areas and plateaus.

In general, the diesel-driven multifunctional fire pump set integrates high efficiency, high reliability, intelligent control, and wide adaptability, and is suitable for various high-standard application scenarios. Its powerful power system, stable water pressure output, intelligent start-up control, compact and convenient structure, simple and easy-to-understand operation, and low maintenance cost are all important reasons why it has become the first choice for fire protection systems in many engineering projects. Whether it is a high-rise building in the city, a storage and logistics park, or a petrochemical heavy industrial site, the diesel fire pump set can provide stable and reliable fire water supply guarantee, play a vital role at critical moments, ensure the safety of people and property, and build a solid fire defense line.