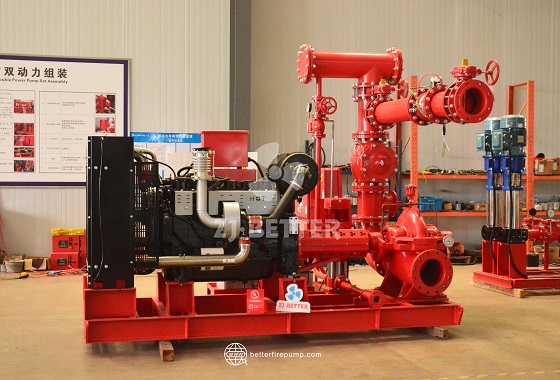

Diesel Fire Pump Systems Commonly Used in Oilfields, Ports, and Large Storage Facilities

High-performance diesel fire pump systems are suitable for oil fields, docks, and large storage facilities. They feature independent power, strong pressure supply, and weather resistance, ensuring continuous fire safety in critical locations.

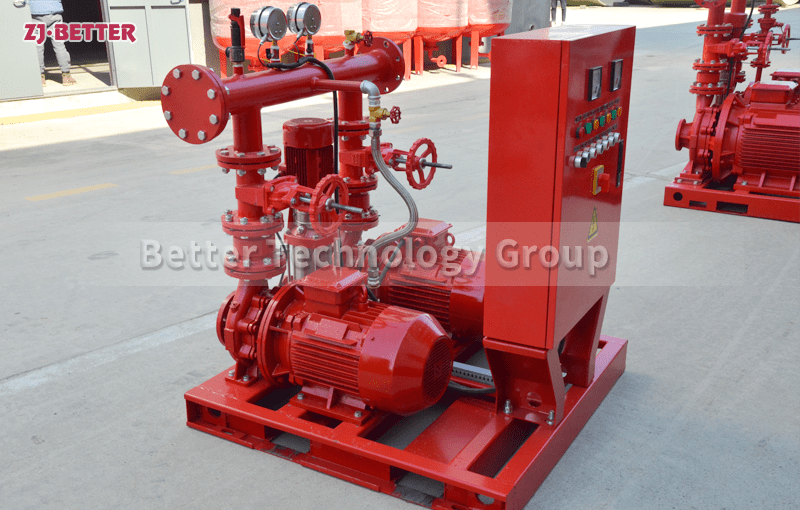

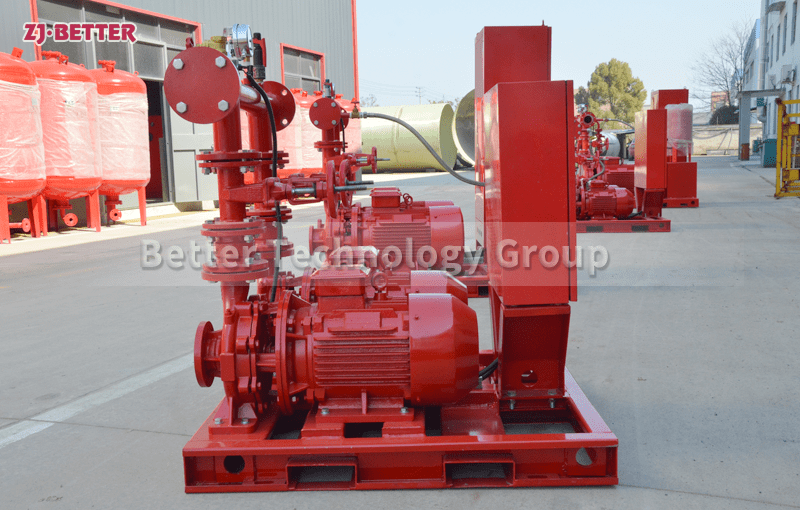

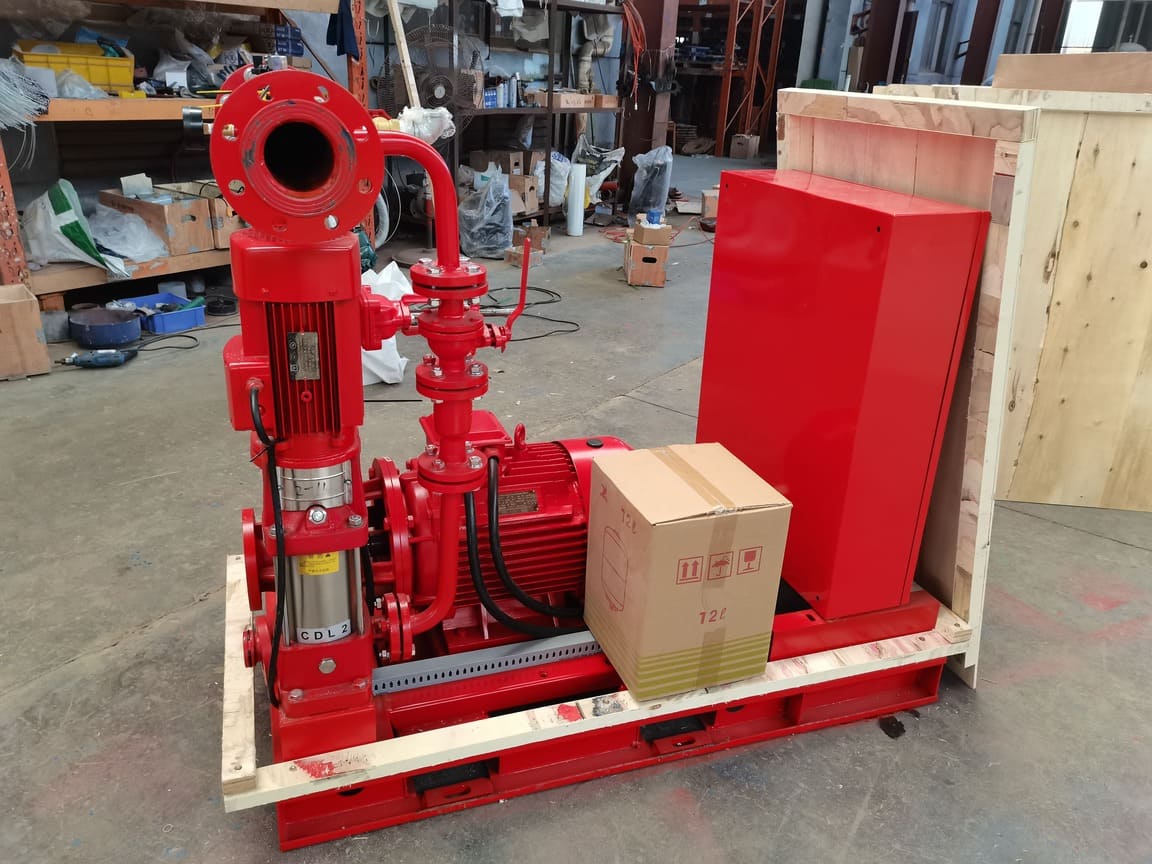

Diesel fire pump systems, commonly used in oil fields, docks, and large storage facilities, serve as a crucial component of fire safety in critical areas. They play a vital role in ensuring stable water supply, independent operation, and rapid response under various extreme conditions. Especially in these high-risk, high-value locations, the fire protection system must guarantee reliable operation even without external power, in harsh weather, complex environments, and during extended periods of standby. Therefore, these diesel fire pump systems not only require higher standards in terms of power performance, structural design, control functions, and material durability, but also must possess core capabilities such as continuous pressure supply, rapid start-up, and long-term stable load operation. This type of fire pump system typically uses a high-power diesel engine as an independent power source, combined with a high-lift, high-flow fire pump and a fully automatic control panel. This enables automatic start-up and intelligent scheduling under all operating conditions, meeting the characteristics of high fire risk in oil fields, dense equipment at docks, large quantities of flammable materials in storage areas, long transportation distances, and high water pressure requirements. It ensures that sufficient fire-fighting water volume and pressure support can be provided immediately in the event of a sudden fire, thereby minimizing the risk of fire spread and improving the overall fire protection level of the facility. These types of equipment play an irreplaceable role in oilfield applications. Since oil and gas well stations, oil transfer stations, and gathering centers are typically located in remote areas with limited and unstable power systems, the independent power characteristics of diesel fire pumps solve the problem of system failure to start in situations without power or during power outages. This allows them to be quickly deployed for firefighting operations even when completely reliant on their own power supply. Furthermore, oilfield areas often experience high temperatures, direct sunlight, dust storms, large temperature differences, and long-term equipment exposure. Therefore, diesel fire pump systems generally employ reinforced chassis, thickened steel plates, anti-corrosion coatings, salt spray resistant treatment, and high-strength couplings to ensure high-performance output even in outdoor environments without external interference. In port environments, diesel fire pump systems face challenges primarily from humid air, salt spray corrosion, high waves, and the risk of fire escalation due to dense stockpiles of oil and cargo. Therefore, such equipment must possess stronger salt spray resistance, a more stable cooling system, and more efficient exhaust and filtration designs to prevent engine performance degradation under prolonged high humidity. Corrosion-resistant pump body materials and piping structures ensure that long-term operation at sea will not result in rust, leakage, or pressure loss. Large warehouses often store large quantities of packaging materials, flammable goods, wooden pallets, chemical raw materials, or high-value cargo. In the event of a fire, the fire spreads extremely rapidly. Therefore, fire pumps must provide high-pressure, high-flow-rate firefighting water in a short time to quickly suppress the fire in conjunction with sprinkler systems, fire monitors, or other firefighting equipment. Diesel fire pump systems, with their powerful output and reliable pressure supply, are ideal for warehouse firefighting. To meet the high-intensity application requirements of these scenarios, these diesel fire pump systems possess a series of key performance advantages. First, its power system uses a high-efficiency diesel engine, which can automatically start within seconds and quickly increase the speed to the rated operating range to achieve immediate pressure supply. Second, the pump body structure mostly adopts a high-lift design, enabling the system to maintain stable pressure under long-distance water transportation conditions, making it suitable for wide-area deployments such as dock shorelines, oilfield pipeline networks, or large warehouses. Third, the entire system typically has automatic detection and automatic start-up functions; when the fire-fighting pipeline pressure drops to the set value, the system will start immediately, ensuring normal fire-fighting operations even in unattended conditions. Fourth, the control panel has fault monitoring capabilities. The system features functions such as operation parameter display, automatic protection, fuel level monitoring, battery charging management, and manual/automatic switching, allowing operators to clearly understand the system status and ensuring that the equipment will not shut down due to malfunctions in case of emergencies. Fifth, the system is often equipped with a large-capacity fuel tank, supporting long-term continuous operation to meet the needs of oilfield nighttime fires, long-distance firefighting at docks, or large-scale fires in storage facilities. Sixth, its base and unit typically adopt an integral welded structure, equipped with shock-absorbing pads and a reinforced chassis, ensuring low vibration and low noise during operation, improving system stability and reducing long-term fatigue damage. Its pump body often uses high-strength, corrosion-resistant alloy materials, and the internal flow channels are designed with fluid optimization to reduce water flow loss and improve overall efficiency, allowing the system to output a larger effective flow rate at the same power. Furthermore, multi-stage sealing structures, high-temperature resistant mechanical seals, and thickened bearings greatly improve the system’s sealing performance and durability, enabling it to operate under high load conditions for extended periods without leakage or performance degradation. To meet the needs of different application scenarios, the entire system can also be configured with different types of linkage systems according to project requirements, such as automatic sprinklers, foam fire extinguishing, fire hydrant systems, remote control, water cannon systems, or chemical-specific fire extinguishing systems. By precisely matching the head and flow rate, it achieves effects suitable for various scenarios. The unit can usually be installed directly outdoors without an additional machine room, greatly reducing installation costs and construction difficulty. In terms of maintenance, this type of diesel fire pump system typically features a simple structure and convenient maintenance. Most vulnerable parts are designed as standard models, making replacement quick and cost-effective. The system also has self-diagnostic and alarm functions, capable of issuing warnings and automatically shutting down to protect the equipment when there is low oil pressure, high water temperature, abnormal speed, or insufficient fuel, ensuring the unit is always in optimal working condition and extending its overall lifespan. Furthermore, the clear wiring layout, open structural design, and modular components facilitate daily maintenance, ensuring that the equipment maintains excellent performance even after long-term operation. It is worth emphasizing that in critical infrastructure such as oil fields and ports, fire protection systems, in addition to stable performance, must also meet international fire protection standards. Therefore, these diesel fire pump systems typically comply with multiple globally recognized standards to ensure their smooth application in international projects and to meet the needs of global customers. With the development of modern industry and the increasing risk of fire, high-performance diesel fire pump systems are no longer just fire-fighting equipment, but crucial infrastructure for ensuring the safety of large industrial facilities, high-value assets, and personnel. Their powerful output, long-term stable operation, independent power supply, weather resistance, and intelligent control functions enable them to maintain high performance even in the most demanding environments. In oil field areas, they provide reliable fire protection for remote well sites; at ports, they withstand salt spray and humid environments and ensure the safety of coastal facilities; in large storage facilities, they provide powerful water supply support for instantaneous high-fire-load environments, enabling rapid suppression of fires and maximizing property protection. In these demanding application areas, diesel fire pump systems, with their comprehensive performance advantages and strong adaptability, have become irreplaceable core fire-fighting equipment, continuously providing safety guarantees and stable fire water supply capabilities for various key facilities, and building a solid defense line for industrial development and safe operation.