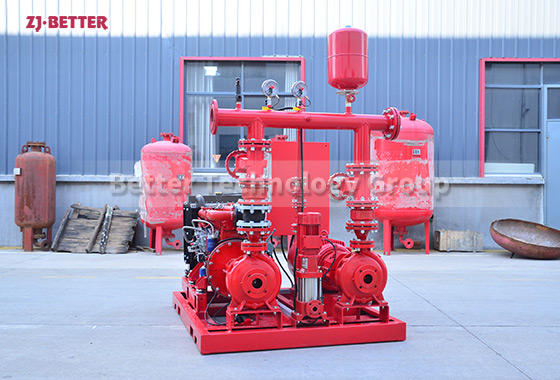

High-Efficiency Low-Flow Jockey Pump Unit: Ensuring Sprinkler and Hydrant Systems Are Always Ready

High-performance vertical pressure-stabilizing pump sets provide continuous and stable pressure support for fire protection systems, ensuring the immediate activation of sprinklers, fire hydrants, and various fire extinguishing devices in emergencies. The equipment features a compact structure, high efficiency, and rapid response, making it suitable for commercial buildings, industrial facilities, warehousing centers, and municipal engineering projects. It provides a reliable, safe, and low-maintenance pressure compensation solution, helping users comprehensively improve the reliability and protection level of their fire protection systems.

As an indispensable core device for pressure maintenance in modern fire protection systems, the high-efficiency, low-flow-rate pressure-stabilizing pump unit primarily ensures that automatic sprinkler systems, gas extinguishing systems, and fire hydrant networks maintain a stable preset pressure in non-fire alarm states, keeping the entire network in a state of readiness for immediate activation. When the main pump stops operating, the pipeline network may experience a pressure drop due to minor leaks, valve leaks, or slight pressure loss at the system’s end equipment. If pressure cannot be replenished in time, it can lead to false triggering of the alarm control system or prevent fire extinguishing equipment from responding quickly in the early stages of a fire. The high-efficiency, low-flow-rate pressure-stabilizing pump unit was developed to solve this problem. Through low-flow, low-energy consumption, and continuous, stable water replenishment operation, it improves system reliability and reduces mechanical wear caused by frequent main pump starts, thus significantly extending the service life of the entire system. This equipment consists of a high-performance vertical stainless steel pump, precision pressure control components, an automated electrical control system, a check valve, safety protection components, and an integrated base. These components work together to achieve comprehensive performance in terms of precise pressure replenishment, intelligent control, safe operation, and long-term durability. One of the greatest advantages of the high-efficiency, low-flow-rate pressure-stabilizing pump unit lies in its highly efficient pressure control capability. Through an intelligent pressure sensing system and electronic pressure switches or frequency converters, the system automatically controls start and stop based on changes in pipeline pressure, ensuring the pressure remains within a set range. The pressure sensor is highly sensitive and responds quickly, detecting minute pressure changes in real time and issuing commands. Upon receiving the control signal, the pump immediately starts, rapidly restoring the pipeline pressure to the standard value, and automatically stops after completing the pressure replenishment task, achieving maximum effect with minimal energy consumption. This operating mode ensures that the fire protection system will not experience false alarms or insufficient power due to pressure instability during extended standby periods, while also minimizing energy waste. Furthermore, this pressure-stabilizing pump unit employs a superior hydraulic design, enabling the pump to maintain high efficiency even at low flow rates, reducing energy losses due to low loads, and ensuring a smooth and reliable pressure replenishment process without pressure fluctuations. The pumps used are typically vertical multistage centrifugal pumps or stainless steel single-stage pumps, flexibly configured according to project requirements. The multistage structure provides higher head and more stable output. Its impeller undergoes precision machining and dynamic balancing, resulting in low vibration and noise during operation. Furthermore, its optimized flow channel structure minimizes fluid friction loss, further enhancing equipment efficiency. The high-efficiency, low-flow, pressure-stabilizing pump unit also boasts excellent corrosion resistance; most of its flow-through components are made of stainless steel, ensuring durability when handling clean fire-fighting water or water with minor impurities. The sealing system employs a mechanical seal structure, ensuring leak-free operation over extended periods and reducing maintenance requirements. The base and support are made of thickened carbon steel with a powder coating, maintaining stable strength even in complex humid and hot environments. The equipment has a compact overall structure and a small footprint, allowing for flexible installation in fire pump rooms, equipment rooms, or small pump stations. It requires minimal space, saving valuable configuration resources in construction projects. The intelligent electrical control system of the high-efficiency, low-flow, pressure-stabilizing pump unit is one of its key advantages. The electrical control system typically includes pressure display, manual/automatic switching, overload protection, phase loss protection, short circuit protection, pump operation indication, and fault alarm functions. Some units utilize variable frequency control, allowing for real-time speed adjustment to achieve more precise pressure regulation and lower energy consumption. When the system experiences abnormal pressure fluctuations, motor overheating, or insufficient water supply, the electrical control system immediately triggers the protection mode and issues an alarm signal to ensure that the equipment is not damaged due to abnormal conditions. This reliable protection mechanism is extremely important for fire protection systems in critical positions, ensuring that the pressure-stabilizing pump operates within a safe zone at all times and that sudden malfunctions do not affect the overall performance of the fire extinguishing system. The automated operation mode allows the pressure-stabilizing pump unit to operate unattended for extended periods, significantly reducing maintenance pressure and improving system management efficiency. The high-efficiency, low-flow pressure-stabilizing pump unit has a wide range of applications, including but not limited to fire protection systems in high-rise buildings, shopping malls, hospitals, schools, underground spaces, industrial plants, public buildings, warehousing and logistics centers, hotels, and other scenarios. Whether it’s a wet sprinkler system, a gas extinguishing system, a foam extinguishing system, or a fire hydrant system, this equipment can serve as a core component for stabilizing pipeline pressure, providing crucial assurance for the reliable operation of the entire system. In fire protection design codes, the configuration of a pressure-stabilizing pump has become a necessity. It not only ensures pressure stability but also directly relates to whether the fire extinguishing system can respond quickly in the event of a fire, impacting personnel and property safety. During construction, the installation and commissioning of the high-efficiency, low-flow pressure-stabilizing pump unit are also very convenient. Its compact structure, simple wiring, and standard interfaces mean it can be put into use simply by completing the layout according to piping and electrical connection requirements. During the commissioning phase, the pressure start-stop range is set according to system needs, enabling automated and highly stable operation. Convenient maintenance is another advantage; the pump body and motor have reserved maintenance space, and key components are easy to disassemble and replace, allowing maintenance personnel to quickly complete daily inspections and repairs, effectively reducing long-term operating costs. In long-term operation, the equipment exhibits extremely high reliability. Its low-load, short-time operation mode significantly reduces mechanical wear, extending the lifespan of the motor and pump body far beyond that of general equipment, providing users with long-term stable value returns. In summary, the high-efficiency, low-flow pressure-stabilizing pump unit, with its multiple advantages such as precise pressure replenishment, high efficiency and energy saving, durability and stability, intelligent monitoring, and convenient maintenance, has become an irreplaceable core device for ensuring pressure stability in modern fire protection systems. It not only improves the reliability of fire extinguishing systems, ensuring rapid activation in the early stages of a fire, but also reduces the overall operating costs of the fire protection system through intelligent and energy-saving design. When a building requires a continuous and reliable fire pressure maintenance capability, this equipment is undoubtedly the best technical solution, and its performance in practical applications has fully demonstrated its important position and irreplaceable role in the field of fire safety.