Precision Design and Strong Power: Advantages of Modern Horizontal Centrifugal Fire Pumps

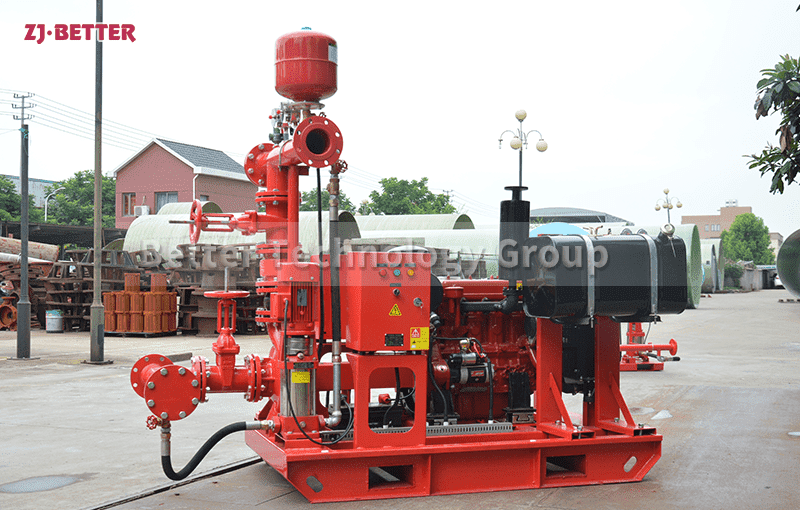

Horizontal centrifugal fire pumps are renowned for their high efficiency, stable operation, and energy-saving design, making them suitable for high-rise buildings, industrial plants, and fire protection systems. Their compact structure, powerful motor, and intelligent control ensure continuous high-pressure water supply, enabling stable operation even under extreme conditions. They provide reliable protection for fire safety and are a top choice for efficient and durable core equipment in modern fire protection systems.

In modern fire protection systems, horizontal centrifugal fire pumps, as one of the core water supply devices, play a crucial role in various buildings and industrial sites due to their high efficiency, stability, and reliability. In the face of emergencies such as fires, the performance of the fire pump directly affects the response speed and fire extinguishing efficiency of the entire system. Horizontal centrifugal pumps, with their precise mechanical structure, optimized hydraulic design, and powerful output, have become an irreplaceable choice in contemporary fire protection engineering. This type of fire pump adopts a horizontal single-stage or multi-stage centrifugal structure, featuring a compact design, stable operation, and easy maintenance. It is widely applicable to urban high-rise buildings, underground projects, warehousing and logistics centers, chemical plants, docks, power plants, and various industrial fire protection systems. Its greatest feature lies in the perfect combination of a high-efficiency motor and an advanced hydraulic model, ensuring a stable and sufficient fire-fighting water pressure under various complex operating conditions. The working principle of a horizontal centrifugal fire pump is based on the process of converting kinetic energy into pressure energy. The motor drives the impeller to rotate at high speed, giving the water centrifugal force and throwing it outwards towards the outer edge of the pump body, forming a high-pressure water flow, thereby achieving continuous water supply output. Thanks to its high-precision dynamic balancing design and efficient hydraulic channels, fluid resistance is significantly reduced, resulting in higher energy utilization and achieving industry-leading overall pump efficiency. Compared to traditional vertical or multistage pumps, the biggest advantage of the horizontal structure lies in its ease of installation and maintenance. Its axial layout allows maintenance personnel to easily disassemble the impeller, shaft seal, or bearing assembly, enabling maintenance without overall relocation and significantly reducing downtime. Furthermore, the pump body and motor are aligned at the same center height, facilitating connection with piping systems, reducing pipeline stress, and extending the overall lifespan of the equipment. In terms of structural design, horizontal centrifugal fire pumps use high-strength cast iron or stainless steel pump bodies, offering excellent pressure resistance and corrosion resistance. The shaft seal typically employs a mechanical seal structure, ensuring no leakage risk under high pressure, high temperature, and long-term operation. The impeller undergoes precision dynamic balancing and CNC machining, improving operational stability and effectively reducing noise and vibration. The motor is usually a high-efficiency, energy-saving motor with insulation class F and protection class IP55 or higher, suitable for harsh working environments. Some models also support variable frequency control, automatically adjusting the speed according to actual pressure requirements through an intelligent speed regulation system to achieve energy-saving operation and optimized system control, making them particularly suitable for fire protection networks that require dynamic adjustment of water supply pressure. In terms of performance, horizontal centrifugal fire pumps have a wide flow range and head coverage, and can be flexibly customized to meet the requirements of different buildings and systems. From medium-pressure water supply in small and medium-sized residential fire protection systems to high-pressure water supply in high-rise buildings or industrial parks, it can provide matching performance output. The maximum flow rate can reach hundreds of cubic meters per hour, and the head can cover tens to hundreds of meters, ensuring sufficient water pressure and flow can be quickly provided in any sudden fire, guaranteeing the immediate response capability of the fire extinguishing system. For complex fire protection systems, horizontal centrifugal pumps can also be combined with pressure-stabilizing pumps, sprinkler pumps, or diesel standby pumps to form an integrated unit, achieving automatic linkage switching through a control cabinet to ensure uninterrupted fire water supply even in the event of a main power failure. From the perspective of operational stability, horizontal centrifugal fire pumps have excellent dynamic balance and vibration control characteristics. The connection between the pump shaft and impeller is precision-fitted to ensure no eccentric wear occurs during long-term operation. High-strength bearings use imported grease to reduce friction loss and temperature rise, improving the overall durability of the system. In long-term operating environments, the anti-vibration design of the pump body and base effectively prevents structural fatigue and deformation, ensuring stable output even under high loads and long operating cycles. Furthermore, some models are equipped with pressure monitoring sensors, temperature detection modules, and intelligent control panels, enabling real-time monitoring of operating status. In case of abnormalities, such as pressure fluctuations or excessively high temperatures, the system will automatically alarm and implement protective shutdown measures, significantly improving equipment safety. Regarding energy efficiency, the horizontal centrifugal fire pump employs a high-efficiency hydraulic model and optimized flow channel design, significantly improving the energy efficiency ratio. Compared to traditional pumps, under the same head and flow conditions, energy consumption is reduced by 10%-25%, with significant energy savings, especially in long-term operating scenarios. Through variable frequency speed control technology, the pump can automatically reduce its speed under low-load conditions, avoiding unnecessary energy waste. This not only reduces electricity costs but also extends the service life of the motor and bearings. For modern buildings pursuing green energy conservation and sustainable development, the application of this energy-saving fire pump is of great significance. Reliability is one of the core indicators of fire pump design. Horizontal centrifugal fire pumps are manufactured in strict accordance with international standards and fire protection codes. Each unit undergoes water pressure testing, performance testing, and dynamic balancing testing to ensure no leakage, abnormal vibration, or performance degradation during actual use. The internal flow channels of the pump body are treated with an anti-rust and anti-corrosion coating, ensuring long-term operation unaffected by water quality. Its strong anti-cavitation capability maintains stable water intake performance even under low suction pressure or high temperature environments, preventing dry running and cavitation damage. For projects with complex installation environments or long-term high-intensity use, this high reliability translates to lower maintenance costs and a higher safety factor. Horizontal centrifugal fire pumps not only boast superior performance but also feature an design that combines industrial aesthetics with engineering practicality. Their compact structure minimizes footprint, facilitating installation in equipment rooms, pump houses, or confined spaces. Inlet and outlet flange dimensions, directions, and materials can be customized to meet different piping layouts and system requirements. For locations requiring quiet operation, vibration-damping bases or soundproof enclosures are available as options to further reduce noise impact. In modern intelligent fire protection systems, horizontal centrifugal fire pumps can be networked with automatic sprinkler systems, wet alarm valve assemblies, and control centers to achieve remote monitoring and automated control. Through PLC systems or IoT modules, managers can view the pump’s operating status, flow rate, pressure, and temperature parameters in real time, enabling remote start/stop and maintenance early warning, further enhancing the intelligence and reliability of the fire protection system. In the future, with the development of smart cities and digital fire protection, this type of intelligent, interconnected horizontal centrifugal fire pump will become the mainstream trend. Overall, horizontal centrifugal fire pumps, with their high efficiency, compact structure, stable operation, energy saving, and durability, have become an indispensable core device in modern building and industrial fire protection systems. Whether in newly constructed high-rise buildings, the renovation of existing fire protection systems, or in high-risk industries such as petrochemicals, power plants, and ports, they can provide a solid guarantee for emergency fire water supply systems thanks to their excellent hydraulic performance and reliable operating characteristics. Choosing a high-performance horizontal centrifugal fire pump means providing a more robust defense for safety and longer-term protection for life and property.