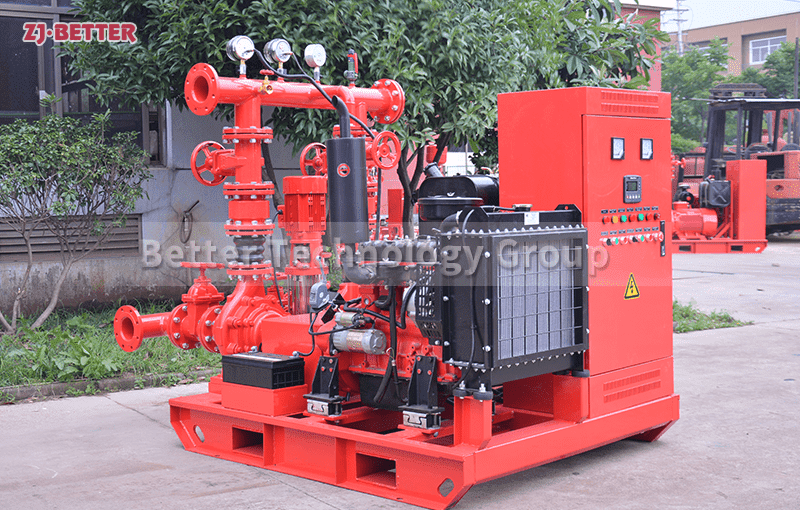

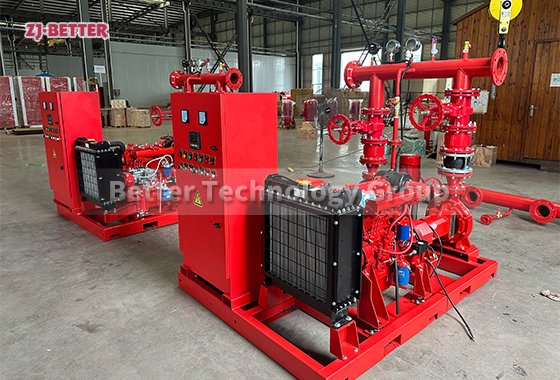

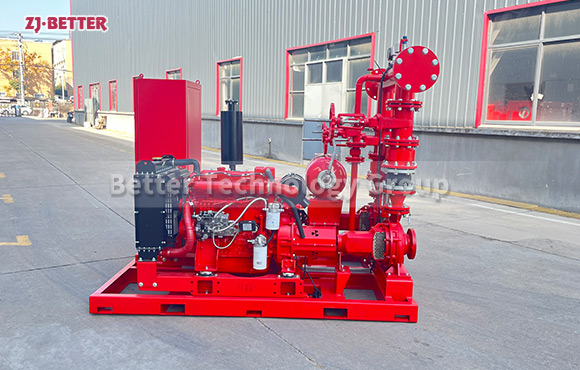

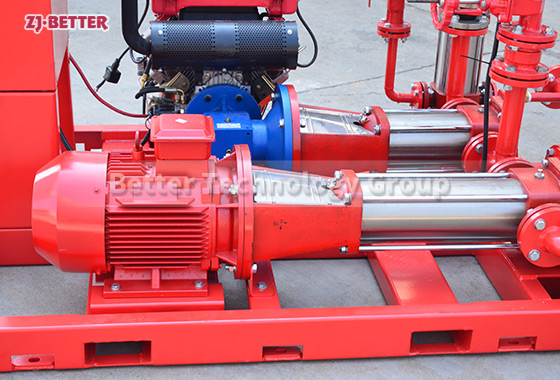

Application Analysis of Diesel Fire Pump Systems Featuring High Cooling Capacity

Diesel fire pump systems with high cooling capacity designed for long-term and high-load operation, delivering stable performance, reliable continuous water supply, and enhanced safety for industrial, standby, and emergency fire protection applications.

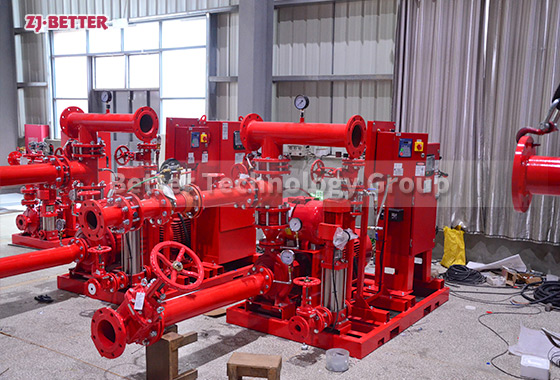

An analysis of the application of diesel fire pump systems with high heat dissipation capacity requires a thorough explanation of their overall structural design, power system matching, and continuous operational performance under high-intensity firefighting conditions. These fire pump systems typically use a diesel engine as their core power source and employ a specially designed high-efficiency cooling system to ensure stable and reliable performance output even under prolonged, high-load operation. In practical firefighting applications, diesel fire pumps often play a crucial role in emergency or backup water supply, especially in scenarios involving power outages, unstable power conditions, or the need for independent water supply. Their operating time is uncertain, and once started, they may need to operate continuously for extended periods. Therefore, the strength of their heat dissipation capacity directly affects the safety and reliability of the entire system. High-heat-dissipation diesel fire pump systems typically employ independent cooling water tanks or high-efficiency radiator structures. By increasing the heat dissipation area, optimizing the air duct layout, and rationally configuring the cooling medium circulation method, the heat generated by the engine under high speed and high load conditions can be quickly dissipated, effectively preventing power attenuation, component aging, or abnormal shutdowns caused by excessive temperature. Compared to ordinary power equipment, firefighting applications place more stringent demands on diesel engines. They not only need to start quickly in emergencies but also maintain stable output under harsh environments and continuous operation. The introduction of a high-heat-dissipation system is precisely to meet these specific requirements. The pump unit is also specifically designed, employing a high-efficiency hydraulic model with smooth internal flow channels. This allows for stable flow and head while minimizing unnecessary energy loss, reducing the overall system operating burden, helping to control engine heat load, and improving fuel efficiency. The complete system typically uses a skid-mounted design, integrating the diesel engine, fire pump, cooling system, control devices, and related piping accessories onto a unified base. This makes the connections between systems more compact and rational, effectively reducing vibration, heat accumulation, or operational inconsistencies caused by dispersed installation. In high-temperature environments or pump rooms with limited ventilation, the advantages of a high-heat-dissipation diesel fire pump system are particularly evident. Through a rational air intake and exhaust path design, hot air can be quickly expelled from the equipment operating area, maintaining the overall temperature balance of the working environment and ensuring the reliability of the equipment during long-term standby. In terms of control systems, these diesel fire pump systems are typically equipped with independent control boxes, featuring automatic start-up, operation monitoring, and fault alarm functions. They can monitor engine temperature, speed, and system operating status in real time, issuing timely warnings when abnormal trends occur, ensuring safe operation of the equipment. For fire protection engineering, reliable start-up and continuous operation are crucial standards for evaluating equipment performance. The high heat dissipation design not only improves the stability of the diesel fire pump during long-term operation but also significantly enhances the system’s safety redundancy under extreme conditions. The rational matching of the fuel system and speed control system ensures stable engine operation under different load conditions, avoiding speed fluctuations or heat concentration caused by sudden load changes, thereby further reducing the risk of system failure. Simultaneously, high-heat-dissipation diesel fire pump systems also offer advantages in maintenance. The clear structural layout and integrated design make daily inspection and maintenance more convenient. Maintenance personnel can intuitively grasp the operating status of the radiator, cooling pipes, and key components, reducing maintenance difficulty and downtime risks. From an application perspective, these fire pump systems are widely applicable to industrial parks, warehousing and logistics centers, infrastructure projects, and locations requiring independent fire water supply. In these scenarios, equipment often faces challenges such as high-intensity operation or high ambient temperatures, making high heat dissipation capacity a key factor in ensuring the reliability of the fire protection system. Comprehensive analysis shows that high-heat-dissipation diesel fire pump systems, through synergistic optimization in power, heat dissipation, and structural design, achieve stable performance output under high-load, long-term operating conditions. They excel in ensuring continuous fire water supply, improving system safety, and adapting to complex operating conditions, making them an important solution for dealing with harsh operating environments in modern fire protection engineering.