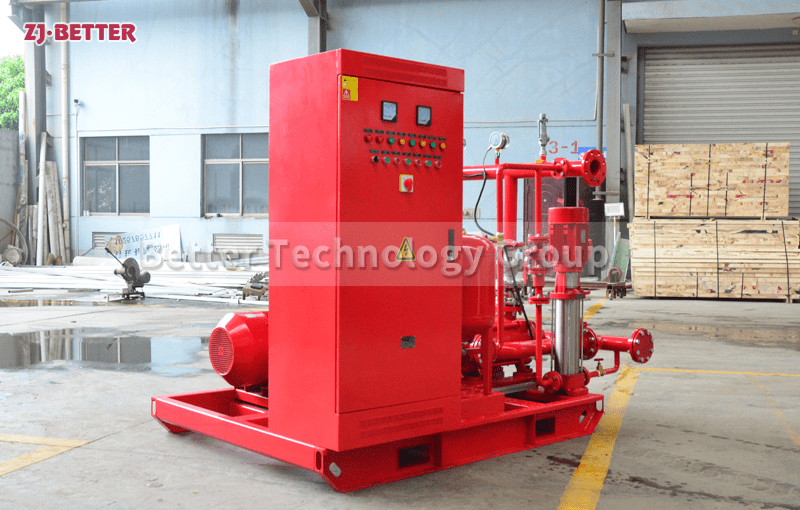

Diesel engine fire pump set is mainly used for pressurization and water delivery of fire system pipelines

Diesel engine fire pump sets are used in fire hydrant fire extinguishing systems and automatic sprinkler fire extinguishing systems in fixed fire extinguishing systems of enterprises, institutions, engineering construction, high-rise buildings, etc. It can transport clear water below 90 °C without solid particles and has similar physical and chemical properties. The water-based medium can also be used for fire protection, domestic and production shared water supply systems and construction, municipal water supply and drainage, etc.

Product features of diesel fire pump set:

1. Automatic start: After the diesel water pump unit receives a fire alarm/pipe network pressure/power failure/or other start signals, it can automatically start within 15 seconds and put into full-load operation;

2. Automatic charging: the battery can be automatically charged by the mains or diesel charging motor to ensure the smooth start of the unit;

3. Automatic alarm: automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, alarm and stop when overspeed;

4. Automatic preheating: make the diesel engine in a standby state to ensure emergency work;

5. Direct connection type: The diesel water pump unit below 360kw adopts the domestic first direct connection technology between the diesel engine and the water pump through an elastic coupling, which reduces the point of failure, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit ;

6. Users can also request to set other alarm outputs (non-standard supply);

7. With telemetry, remote signaling, remote control functions (non-standard supply);