How to Ensure Your Fire Pump Meets NFPA 20 Standards

Discover how to comply with NFPA 20 fire pump requirements by following installation, performance, and testing guidelines to ensure safety and code compliance.

Fire pumps are critical components of building fire protection systems, and compliance with NFPA 20 is essential for both safety and legal approval. NFPA 20, developed by the National Fire Protection Association, sets the standard for installing stationary fire pumps for fire protection. In this article, we’ll guide you step-by-step through what it takes to ensure your fire pump installation meets NFPA 20 requirements.

1. Choose an Approved Fire Pump

NFPA 20 requires that fire pumps be listed and approved for fire protection service. This means your pump should be:

-

UL Listed

-

FM Approved

These certifications guarantee the pump has passed rigorous testing and meets performance standards specific to firefighting applications.

2. Proper Fire Pump Sizing and Performance

Your fire pump must be capable of delivering the required flow (GPM) and pressure (psi or bar) as determined by your fire protection system. According to NFPA 20:

-

The fire pump must supply 100% of rated flow at rated pressure.

-

It must also deliver 150% of rated flow at 65% of rated pressure without overheating or failing.

-

The shutoff (churn) pressure must not exceed 140% of rated pressure.

Always perform hydraulic calculations before selecting your pump to ensure full compliance.

3. Follow Installation Guidelines

NFPA 20 specifies exact requirements for the installation of fire pumps. Key points include:

-

Pump Room Location: It must be enclosed, accessible, and protected from flooding and freezing.

-

Suction Piping: Must be sized properly and installed to prevent cavitation or air entrapment.

-

Pump Foundations: Should be rigid, level, and capable of minimizing vibration.

-

Clearance: Sufficient space must be provided around the pump for maintenance and inspection.

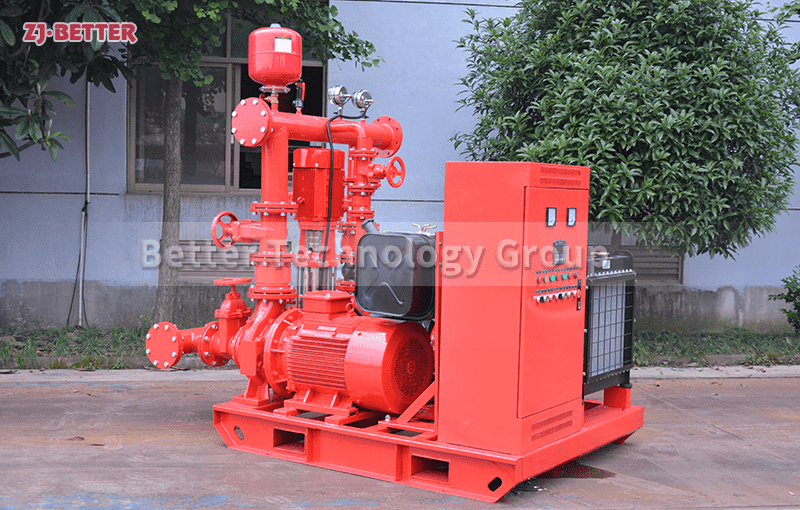

4. Use Compliant Controllers and Power Supply

Fire pump controllers must also be listed for fire protection use. NFPA 20 specifies:

-

Electric Fire Pumps must have a dedicated power supply with disconnects located properly.

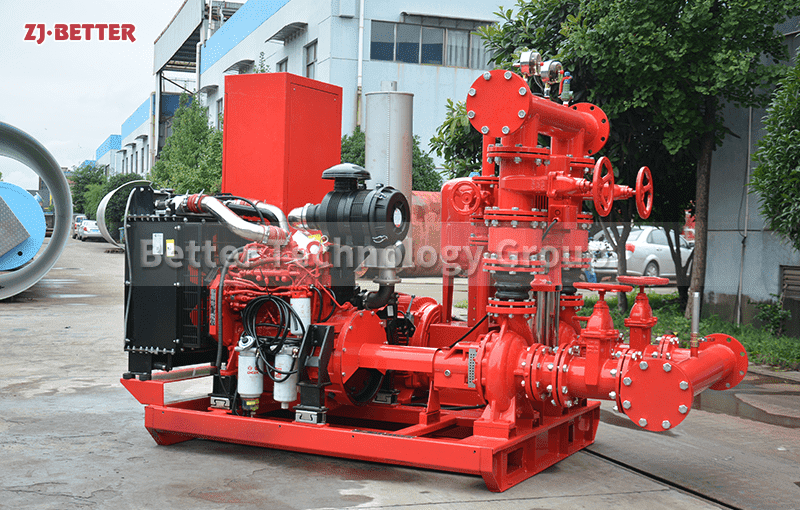

-

Diesel Engine Pumps must have reliable fuel supply, battery systems, and ventilation.

-

Controllers must have manual start, automatic start from pressure drop, and emergency run features.

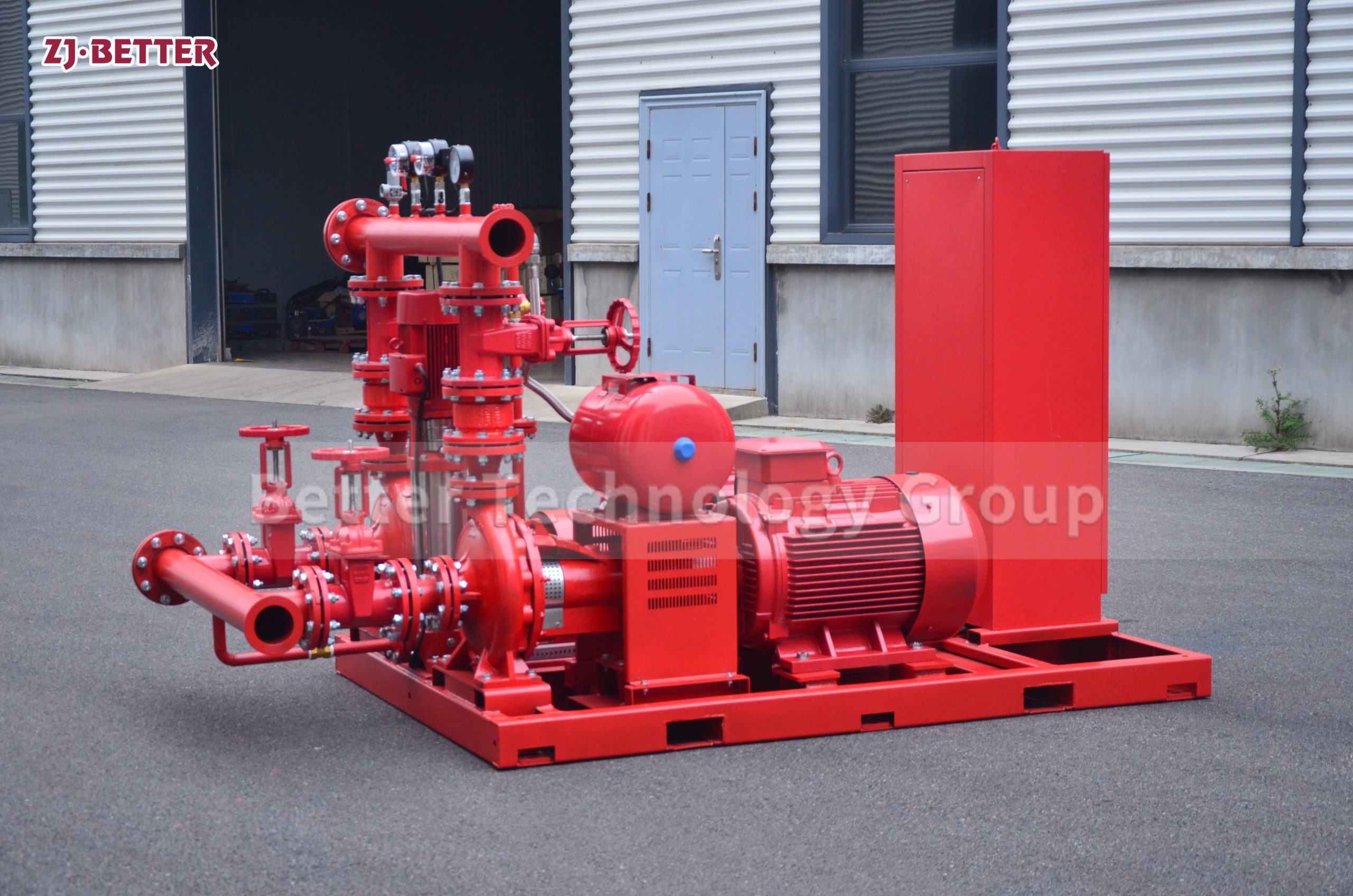

5. Ensure the Right Test Equipment is Installed

To meet NFPA 20 testing requirements, you must include:

-

A flow meter or test header for full-flow testing

-

Pressure gauges on suction and discharge sides

-

A circulation relief valve for diesel pumps

-

Temperature and tachometer gauges (diesel pumps)

These components allow routine testing without disrupting the main system.

6. Perform Acceptance Testing and Commissioning

Before the system becomes operational, NFPA 20 mandates acceptance testing, including:

-

No-flow (churn) test

-

Full-flow test using test header

-

Controller and alarm system tests

-

Automatic start-up test

All test results should be documented and certified.

7. Schedule Regular Inspection, Testing & Maintenance (ITM)

NFPA 25 works alongside NFPA 20 and sets the standard for ongoing maintenance. Key requirements include:

-

Weekly churn testing

-

Monthly battery checks (diesel)

-

Annual flow test

-

Periodic inspection of valves, piping, gauges, and controllers

Conclusion

Meeting NFPA 20 standards isn’t just about avoiding penalties—it’s about saving lives in emergencies. By following certified installation practices, selecting listed components, and regularly testing your system, you can ensure your fire pump provides reliable protection when it matters most.