Amidst the increasingly diverse demands of modern firefighting and emergency response, a type of equipment characterized by high mobility, powerful power output, and wide applicability has gradually become a focus of market attention: the mobile diesel fire pump. Traditional fixed water supply equipment often struggles to be quickly deployed and flexibly deployed, particularly in urban fringe areas, industrial construction sites, petrochemical plants, ports, and remote areas without access to municipal power. The mobile diesel fire pump is an ideal solution for this challenge. Powered by a diesel engine, this device combines a high-performance centrifugal pump, a pressure stabilization system, a mobile trailer platform, and an intelligent control module, achieving a perfect combination of high head, large flow, fast start-up, and adaptability to all scenarios. It can operate independently in environments without power supply and has minimal terrain requirements, offering exceptional maneuverability and rapid on-site response. It is a critical firefighting piece of equipment for multi-scenario, multi-industry, and multi-disaster response.

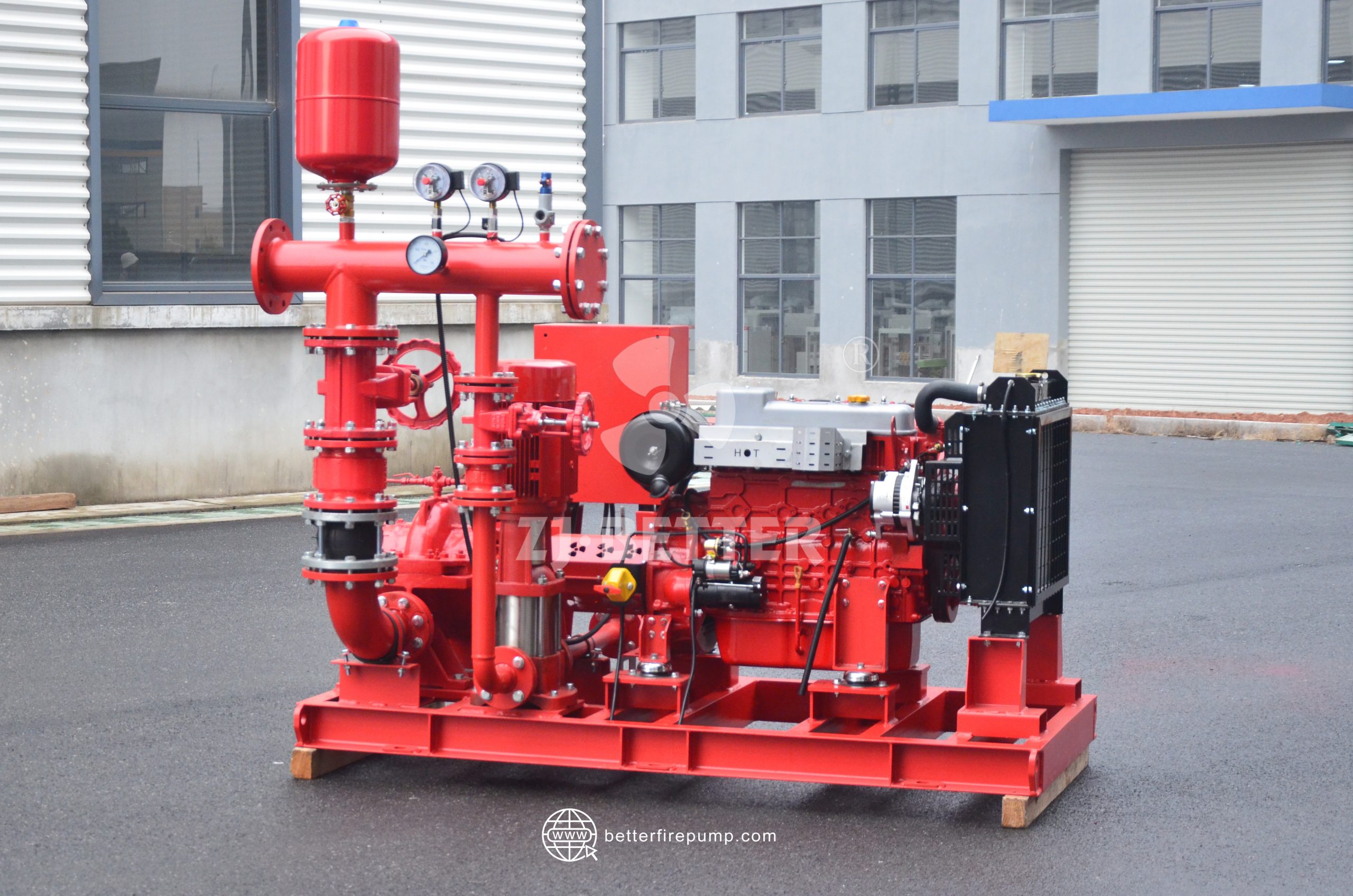

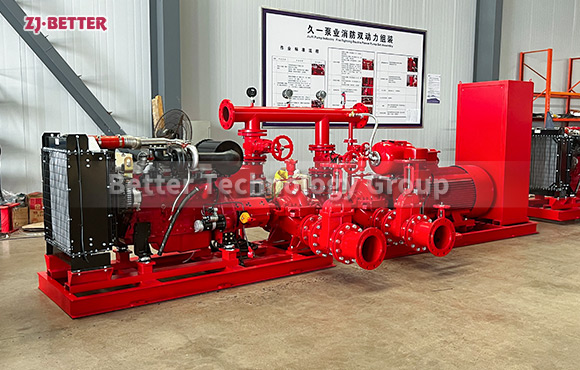

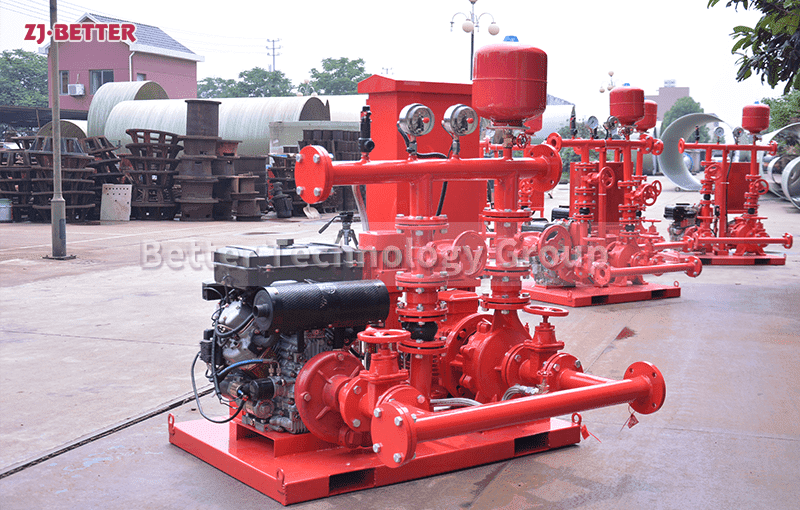

The mobile diesel fire pump utilizes a modular design. By seamlessly integrating the diesel power unit, water pump system, control system, and chassis, it significantly enhances overall stability and transportability while also simplifying and facilitating on-site installation and operation. The entire system features a compact and rational structural layout, with the pump body and electrical control box separated by separate compartments. This prevents heat interference with control components and facilitates routine maintenance and inspection. The equipment is also equipped with high-strength rubber tires, mechanical outriggers, and a towing hook, enabling multiple towing methods, whether manual or motorized, ensuring deployment in the shortest possible time. Furthermore, to meet the diverse pumping parameter requirements of different scenarios, the mobile pump unit supports a variety of head and flow configurations, allowing customers to select the appropriate pump model and diesel power unit based on their specific operating conditions to achieve the optimal balance between efficiency and cost.

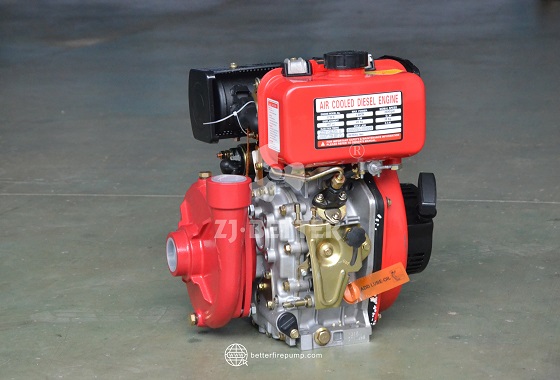

From a practical firefighting perspective, mobile diesel fire pumps demonstrate significant advantages in initial emergency response. When fires occur in remote areas beyond the reach of fixed pipeline networks, such as factories, farmland storage, and mountain camps, traditional rescue teams often miss the best opportunity to extinguish fires due to difficulties in mobilizing equipment and delayed water supply. However, the mobile diesel pump, with its quick-start function, can be deployed in a fraction of the time. Its built-in starting battery and throttle adjustment system ensure stable operation in extreme weather conditions, including cold, damp, and high temperatures. In addition, some models feature self-priming and a dual-intake design, allowing them to draw water directly from a variety of sources, including ponds, rivers, and storage tanks, providing reliable water supply in water-scarce locations. This flexible and efficient water replenishment capability makes them highly valuable for various applications, including temporary water supply, drought relief water transfer, and water diversion for large-scale projects.

Industrial construction sites are another important application for mobile diesel fire pumps. Especially in high-rise building construction, tunnel construction, and subway tunnel boring systems, firefighting water sources are often unevenly distributed or difficult to access locally, and on-site power consumption is often limited by high-power loads. In these situations, mobile diesel pumps, with their powerful diesel power and stable water supply, eliminate the need for external power sources and provide reliable support for temporary firefighting systems or construction sprinkler systems. Their ability to operate continuously for hours or even longer makes them a standard feature of safety management on large construction sites. Furthermore, their low noise levels and excellent emission control meet environmental standards in many regions, minimizing nuisance and pollution even in densely populated or environmentally sensitive areas.

Ports and terminals, as specialized operating environments, place higher demands on firefighting equipment for mobility, corrosion resistance, and seawater adaptability. Mobile diesel fire pumps can be customized with stainless steel pump bodies, copper impellers, and anti-corrosion coatings to effectively combat the corrosive effects of sea breezes, humidity, and saline water sources. In practice, these units are often deployed in container areas, fuel loading and unloading areas, yard boundaries, or near boarding access points, supplementing or supporting fixed firefighting equipment. Their flexible towing capabilities, convenient piping layout, and stable pumping pressure enable them to quickly take over water supply duties in emergencies, effectively preventing the spread of fires to ships, containers, or flammable areas. Furthermore, some units can be connected to accessories such as spray cannons and foam mixers to accommodate special situations like oil fires, further expanding their scope of use and functionality.

These mobile pump units have also demonstrated exceptional performance in agriculture and water conservancy. Whether used for drought relief irrigation, pumping and draining open channels, or sudden flooding, their powerful suction capacity and continuous operation capabilities meet the demands for rapid pumping and delivery from multiple on-site water sources. Its compact design takes up little space, and its simple operation eliminates the need for skilled labor. Startup and shutdown can be completed by one person, significantly reducing operational and maintenance burdens at the grassroots level. Some users also integrate this device with reservoirs and sprinkler irrigation systems to establish emergency water diversion systems, ensuring on-demand water supply for agricultural production.

In terms of product safety, the mobile diesel fire pump is equipped with multiple protection mechanisms, including oil and water temperature alarms, overspeed shutdown, and dry-run protection, effectively preventing operational anomalies from causing equipment damage or accidents. Furthermore, its control system supports manual and automatic mode switching, facilitating flexible operation in diverse operating environments. Some high-end models also incorporate a remote monitoring module, allowing users to view operating data, fuel consumption, and alarm notifications via mobile phone or computer, enhancing the system’s intelligent management capabilities. Each unit undergoes rigorous high-voltage, field-based pumping, and continuous operation testing before shipment, ensuring that each unit is fully operational and capable of handling any complex application.

In summary, mobile diesel fire pumps, with their superior structural design, outstanding power performance, wide adaptability, and intelligent control systems, have become critical equipment for fire emergency response across multiple industries and scenarios. From construction sites to docks, from industrial plants to rural irrigation, from power outage areas to natural disaster sites, this equipment has invariably demonstrated flexible, efficient, and reliable operational capabilities. It is not only a firefighting device but also an indispensable component of the modern emergency management system, providing strong technical support for protecting people’s lives and property and improving emergency response capabilities. In the future, with the accelerated urbanization process and the frequent occurrence of extreme weather events, the demand for mobile diesel fire pumps is bound to expand further, and their technology will continue to upgrade towards greater intelligence, greater environmental protection, and more functionality, becoming the backbone of emergency response forces in various industries.