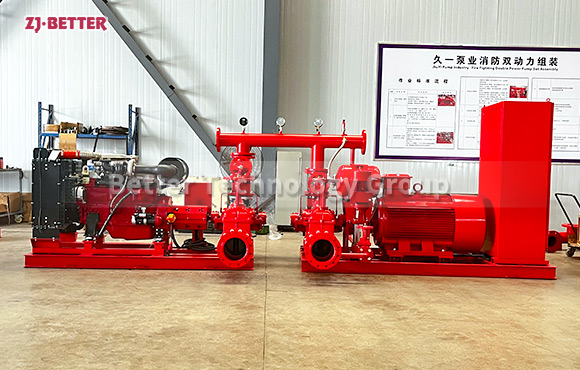

Intelligent Diesel Control Cabinet Fire Pump Set: High-Efficiency Drive System for Reliable Fire Water Supply

Discover the Intelligent Diesel Control Cabinet Fire Pump Set—engineered for high-efficiency water delivery, smart automation, and unmatched reliability in critical fire protection systems. Ideal for industrial and remote installations.

The Intelligent Diesel Control Cabinet Fire Pump Set is a state-of-the-art firefighting solution engineered to provide reliable and efficient water supply in critical emergency situations. Designed with advanced technology and robust construction, this pump set integrates a diesel engine, intelligent control cabinet, centrifugal pump, and auxiliary systems into a cohesive unit optimized for fire protection applications. At its core, the system is powered by a high-performance diesel engine known for its superior torque, fuel efficiency, and endurance under extreme operational conditions. This diesel drive ensures uninterrupted functionality even in scenarios where electric power sources may fail, making the pump set an indispensable component in fire safety infrastructure across industrial zones, commercial complexes, municipal facilities, and remote locations. The centrifugal fire pump attached to the diesel engine is engineered to deliver high flow rates and stable pressure across a wide range of operational loads. Utilizing hydraulic designs that reduce internal losses and enhance volumetric efficiency, this pump guarantees consistent water output needed for sprinkler systems, hydrant lines, and foam-based suppression systems. The impeller and casing are constructed from corrosion-resistant materials, ensuring durability even in aggressive water environments or when drawing water from natural sources such as lakes or reservoirs. A key innovation in this system is the integration of the intelligent control cabinet. This cabinet is equipped with a programmable logic controller (PLC) or microprocessor-based control panel that allows for real-time monitoring, automated operation, fault diagnostics, and event logging. Operators can set customized parameters such as pressure thresholds, startup delays, and automatic switchover from main to backup pump based on field requirements. Visual indicators, alarms, and a user-friendly interface enhance situational awareness and reduce human error during fire emergency response. Furthermore, the control cabinet supports remote communication protocols such as RS485, Modbus, or TCP/IP, enabling integration into Building Management Systems (BMS) or Fire Alarm Control Panels (FACP). This enhances the ability of safety personnel to monitor pump status from a centralized location, improving response times and overall system reliability. In terms of auxiliary features, the system includes an electric starter, battery bank, fuel tank, cooling system, exhaust manifold, and vibration isolation mounts. These components are designed with redundancy and performance in mind. The electric starter, backed by a dual-battery system, ensures rapid ignition in low-temperature conditions or after extended standby periods. The fuel tank is engineered with anti-corrosion coatings and safety valves to prevent fuel leakage or contamination, and can be sized to meet operational autonomy requirements of up to 8 hours or more. The integrated cooling system—often a water-to-air or radiator-cooled configuration—ensures stable engine temperature during prolonged operation, thus extending engine life and maintaining consistent output. The entire diesel fire pump set is mounted on a robust steel base frame with anti-vibration pads to minimize mechanical shock and acoustic noise during operation. Its compact footprint allows for easy installation in mechanical rooms, outdoor pump stations, or prefabricated skid units. Optional weatherproof or sound-attenuated enclosures are available to enhance environmental resistance and noise control. From a performance perspective, this pump set is designed to comply with international fire protection standards such as NFPA 20, EN12845, GB27898, and others depending on client requirements. Typical performance metrics include flow rates ranging from 100 GPM to 5000 GPM and pressure heads up to 20 bar or higher, customizable to project-specific hydraulic demands. The system undergoes rigorous factory testing prior to delivery, including hydrostatic pressure tests, functional testing, and endurance run tests to ensure performance consistency and reliability. One of the defining advantages of the Intelligent Diesel Control Cabinet Fire Pump Set is its autonomous operation capability. In the event of a fire, the system can be activated automatically through signals from fire alarm devices or pressure drops in the pipe network. Even in the absence of electric grid support, the diesel engine will engage and supply water with no manual intervention required. This independence makes it ideal for installations in off-grid industrial sites, oil refineries, chemical storage facilities, ports, or mountainous areas where power instability is a concern. Moreover, the system supports seamless integration with jockey pumps, electric fire pumps, and standby pump units to create a fully redundant and tiered firefighting strategy. These configurations allow operators to deploy different pump sets based on pressure demand or system zoning, thereby optimizing energy consumption and prolonging equipment lifespan. In terms of maintenance, the intelligent system includes features such as scheduled self-start routines, run-hour recording, filter status monitoring, and predictive maintenance alerts. These help facility managers to implement proactive maintenance strategies and reduce unplanned downtimes. The built-in test modes and manual override functions further allow for periodic inspection and operator training without disrupting the actual fire safety readiness. With a modular design, the pump set can be customized in terms of motor power, pump size, control logic, and mounting orientation to match the specific needs of hospitals, airports, data centers, logistics hubs, and large commercial towers. Accessories such as automatic air release valves, pressure relief valves, flow meters, and check valves are available as part of the package to enhance hydraulic system balance and safety. Environmentally, the pump set can be supplied with low-emission diesel engines that meet Tier 3 or Tier 4 EPA standards or equivalent, reducing carbon footprint and ensuring regulatory compliance in urban deployments. Fire protection consultants and EPC contractors often favor this system due to its plug-and-play nature, factory pre-assembled construction, and the ability to integrate it quickly into new or retrofit projects. In conclusion, the Intelligent Diesel Control Cabinet Fire Pump Set is a superior solution for facilities that demand dependable, flexible, and high-performance fire protection. Its diesel-driven autonomy, smart controls, durable construction, and broad configurability make it a leading choice for critical infrastructure safety. Whether installed as a primary firefighting system or a backup to electric pump sets, this diesel pump package offers unmatched operational assurance and peace of mind to property owners, safety engineers, and facility managers worldwide.