Vertical Multistage Fire Pump: High-Efficiency Pressure Boosting for Accurate Fire Protection Requirements

Vertical multistage fire pumps feature high head, high efficiency, and precise pressurization capabilities, making them suitable for high-rise buildings, commercial complexes, and industrial fire protection systems, providing stable and reliable fire pressure assurance. This article provides an in-depth introduction to their structural advantages, performance characteristics, and application value, helping to create efficient and safe fire water supply solutions.

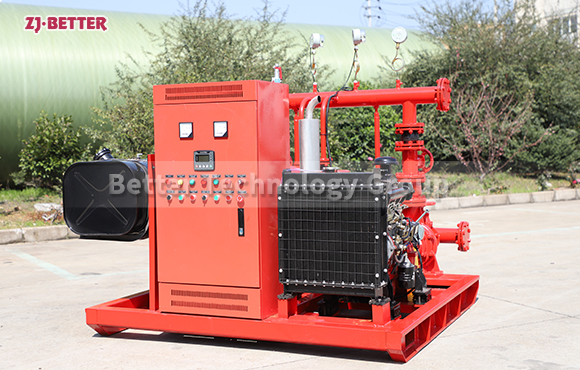

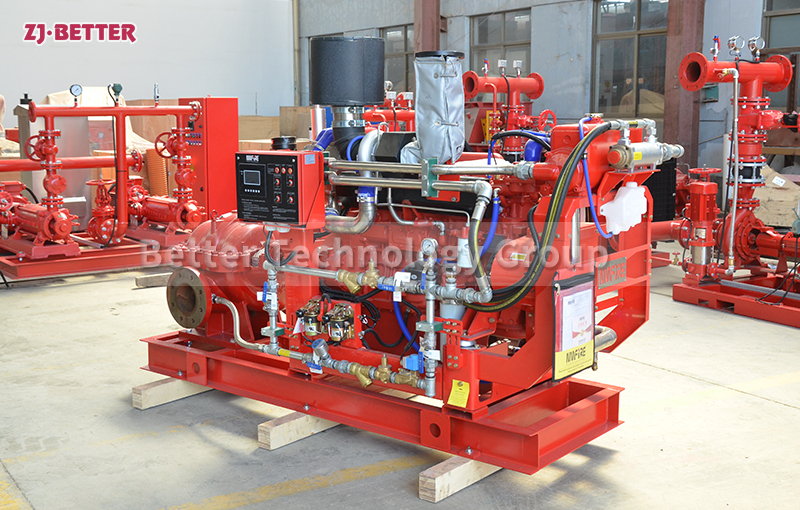

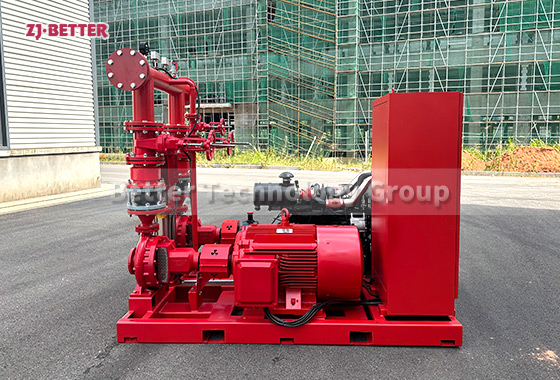

Vertical multistage fire pumps, as an indispensable core device in modern fire protection systems, are favored by various engineering projects due to their high head, high stability, and multi-stage pressurization structure. In various settings such as large commercial complexes, hospitals, schools, industrial plants, warehousing and logistics centers, high-rise buildings, underground spaces, and municipal fire water networks, they fully demonstrate their ability to precisely match fire pressure demands, ensuring a highly efficient, continuous, and powerful fire water source in the shortest possible time during a fire, providing reliable protection for the fire extinguishing system. The vertical multistage fire pump adopts a vertical structure design, occupying a very small area. Compared to traditional horizontal pumps, it not only saves more space but is also easier to install in fire pump rooms or confined machine room environments, making it particularly suitable for space-constrained locations such as high-rise buildings and underground projects. Its coaxial design of the motor and pump body reduces transmission energy loss, resulting in higher operating efficiency, a more compact mechanical structure, smooth overall operation, and low noise. It maintains stable output even during long-term operation, ensuring a continuous high-pressure water supply to the fire protection system in emergency situations. The multi-stage impeller series pressurization method is one of the core advantages of this pump. By stacking multiple impellers, the outlet pressure can be significantly increased, making it outstanding in meeting high-lift requirements. Whether for sprinkler systems, fire hydrant systems, or pressure stabilizing devices, the multi-stage structure can precisely match the actual pipeline pressure requirements, thereby achieving the stable water supply pressure required for high-rise buildings or complex fire protection systems. Under the stringent requirements of instantaneous fire start-up, vertical multi-stage fire pumps have rapid response capabilities, quickly entering rated operating status upon receiving instructions to ensure the best time for fire suppression in the early stages of a fire. In addition, the multi-stage structure has stronger adaptability to pressure fluctuations in different areas, and can flexibly customize operating parameters by adjusting the number of stages and impeller configuration, making it more suitable for the personalized needs of different projects. The material design of vertical multi-stage fire pumps also reflects their safety and durability. Key components such as the pump body and pump shaft are usually made of corrosion-resistant alloy materials or stainless steel structures, which can maintain stable performance in media that are in long-term contact with clean water or trace impurities, avoiding efficiency reduction caused by rust. The mechanical seal structure uses high-temperature and wear-resistant materials, maintaining excellent sealing performance even under high-pressure and high-load conditions, ensuring no leakage and further enhancing system reliability. Vertical multistage fire pumps also boast high compatibility in terms of motors and control systems. They can seamlessly integrate with various fire control cabinets, automatic control systems, and remote monitoring systems, supporting functions such as emergency automatic start, manual start, linkage start, and fault alarms, meeting the needs of modern intelligent fire control. Under the management of the fire monitoring center, the equipment can monitor information such as flow rate, pressure, current, and operating status through real-time data feedback, making the fire protection system more intelligent and visualized. To enhance overall operational reliability, many vertical multistage fire pumps also employ dual-pump or multi-pump standby modes, operating in conjunction with pressure-stabilizing pumps, sprinkler pumps, and fire hydrant pumps, automatically adjusting their operating status based on the monitored system pressure. When the system pressure drops to the set value, the pressure-stabilizing pump starts operating first, while under conditions of increased water consumption, the main pump automatically starts, ensuring that the system pressure is always maintained within a reasonable range. This multi-pump joint operation mode not only improves the overall efficiency of the fire protection system but also further guarantees safety in critical moments. Vertical multistage fire pumps are relatively easy to install and maintain. Their vertical structure allows for smoother pipeline layout, often requiring only flange connections for inlet and outlet installation. Furthermore, the shorter axial dimension of the pump makes the pump body more stable, reducing reliance on foundations and lowering installation costs. Maintenance is minimal, requiring only periodic checks of the mechanical seal, motor bearings, impeller wear, and internal cleanliness of the pump body. This low workload makes them suitable for long-term operation projects. Their energy efficiency is also outstanding. Vertical multistage fire pumps utilize high-efficiency motors and optimized hydraulic structures, enabling each impeller stage to effectively increase pressure and reduce hydraulic losses. Overall energy consumption is lower than similar products, saving significant electricity costs for long-term fire protection systems. Even in non-fire conditions, the pressure stabilization function maintains stable pipeline pressure with low energy consumption, avoiding unnecessary energy consumption caused by frequent start-stop cycles. With their advantages of high head, high efficiency, small footprint, stable operation, low noise, and easy maintenance, vertical multistage fire pumps are widely used in modern building fire protection systems. Whether in high-rise buildings, commercial complexes, or large-scale industrial projects, it ensures a rapid response and continuous, reliable water supply for fire suppression systems through precise pressure control, efficient pressurization capabilities, and superior performance. It not only enhances fire safety levels but also provides more intelligent, energy-efficient, and reliable fire water supply solutions for engineering projects, becoming an irreplaceable and crucial piece of equipment in numerous fire protection engineering designs. Leveraging the high efficiency and flexible adaptability of vertical multistage fire pumps, each project can achieve optimal fire hydraulic configuration, providing powerful water pressure support in emergency fire situations and building a robust defense for personal safety and the protection of building property.