Low-Noise Vertical Fire Pump: A Fire System Upgrade Balancing Performance and Comfort

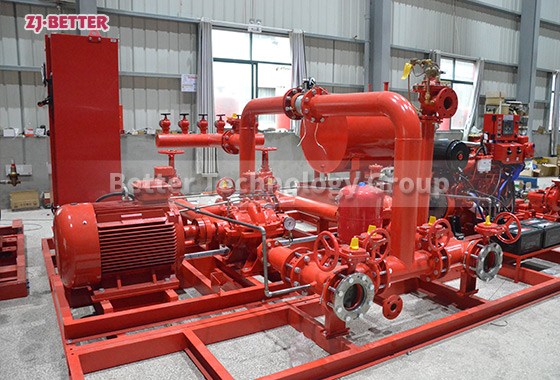

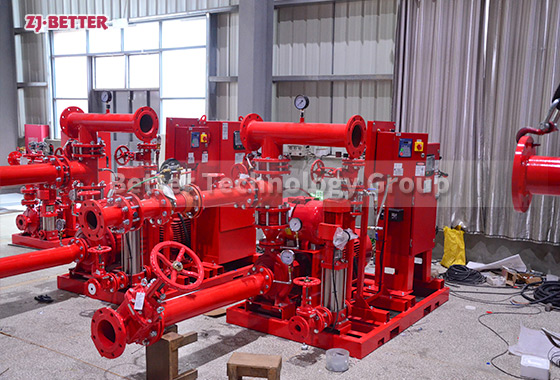

Low-noise vertical fire pump designed for high-performance fire protection systems, offering stable pressure, efficient water delivery, compact installation, and reduced operational noise. Ideal for high-rise buildings, commercial facilities, and industrial fire safety upgrades.

Low-noise vertical fire pumps, as an indispensable core device in modern building fire protection systems, have become the preferred type of fire pump for many construction projects, industrial facilities, and commercial venues due to continuously upgrading fire protection standards and increasing demands for comfortable environments. With accelerated urbanization, various types of buildings place higher demands on the stability, response speed, efficiency, and environmental friendliness of fire water supply systems. Low-noise vertical fire pumps are high-performance pump sets developed to meet these requirements. While achieving high flow rate, high head, and continuous operation, they significantly reduce operating noise through structural optimization and power matching, making them a fire system upgrade solution that balances safety and user experience. These vertical pumps exhibit stable hydraulic characteristics during operation, with precise and compact coordination between components. In particular, the vertical structure design allows for direct coaxial connection between the pump body and motor, reducing resonance and noise diffusion during mechanical energy transmission and greatly improving quiet operation. Simultaneously, the vertical structure offers advantages such as small footprint, convenient installation, and flexible layout, making it suitable for building scenarios with limited machine rooms and requiring compact installation. Therefore, it can meet stringent fire water supply requirements in high-rise residential buildings, office buildings, shopping malls, and large industrial plants. Furthermore, low-noise vertical fire pumps are made of high-quality cast iron, alloy steel, or stainless steel to ensure high strength, wear resistance, and corrosion resistance. Their internal impellers are optimized through hydraulic model design, resulting in smoother flow channels, higher efficiency, and lower vibration. This ensures the pump unit can maintain stable operation under prolonged high-intensity conditions, which is particularly important for fire protection systems, as fire pumps need to start immediately and maintain a stable water supply in emergencies, allowing no delays or performance degradation. To achieve superior quiet operation, the design typically employs multiple noise reduction measures, including thickened pump body walls, optimized flow channel structure, reduced impeller hydraulic impact, vibration-damping bases, and motor noise reduction technology. These measures ensure that the pump maintains a low noise level under rated operating conditions, preventing noise interference to surrounding machine rooms, duty rooms, or residential spaces. Therefore, they are particularly suitable for civil buildings with high noise requirements. Low-noise vertical fire pumps offer significant performance advantages. Their rated flow and head can be flexibly customized to meet the fire protection needs of different buildings, satisfying the water requirements of sprinkler systems, fire hydrant systems, and pressure stabilization systems. They can also form a complete fire water supply system with fire control cabinets, piping systems, and valve equipment. Furthermore, the pump has rapid start-up capability, reaching a stable operating state in a very short time upon receiving a fire signal, ensuring sufficient water volume and pressure are delivered to the fire protection network, maintaining the reliability and emergency response speed of the building’s fire protection system. The motor typically adopts a high-efficiency and energy-saving design, featuring low temperature rise, stable power, and low operating noise. Combined with the vertical structure, it reduces mechanical losses, significantly extending the overall lifespan of the machine. The low-noise vertical fire pump has a compact structure and is easy to maintain. The pump body, motor, and shaft system are highly integrated, allowing maintenance personnel to easily complete routine inspections, seal replacements, and clearance adjustments without disassembling complex components, reducing downtime and improving efficiency. Due to its vertical installation method, it can be directly connected in series in the fire protection piping system, resulting in a simpler piping layout. It eliminates the need for additional large pump foundations or large machine room space, saving equipment installation costs for buildings. The pump’s mechanical seal is made of high-temperature resistant, wear-resistant, and corrosion-resistant high-quality materials, capable of withstanding long-term pressure changes and high-speed rotational friction, ensuring no leakage during emergency startup and thus guaranteeing system safety. In terms of hydraulic performance, the low-noise vertical fire pump employs an advanced hydraulic model, optimizing the impeller curve, volute shape, and internal flow channels through computational fluid dynamics analysis, enabling long-term operation in the high-efficiency range, reducing energy loss, and significantly suppressing hydraulic noise. The impeller’s dynamic balance is rigorously calibrated to maintain stability during high-speed rotation, avoiding additional noise caused by vibration and providing a foundation for the pump’s quiet operation. For fire protection systems requiring long-term standby, the pump’s energy-saving performance effectively reduces building operating costs, making it a widely adopted fire protection device in modern engineering projects. In addition to its structural and performance advantages, the low-noise vertical fire pump also meets multiple international fire protection standards. Its design and manufacturing strictly adhere to fire pump performance testing specifications, such as flow rate testing, pressure testing, startup performance testing, sealing testing, noise testing, and continuous operation testing, ensuring that each pump meets the specified fire protection performance requirements before being put into use. This not only demonstrates its reliability but also ensures sufficient pressure and water volume in actual fire situations, supporting the flow requirements of all fire extinguishing systems, including sprinkler head opening, fire hydrant discharge, and fire monitor spraying. Low-noise vertical fire pumps are suitable for various locations requiring efficient, stable, and low-noise fire water supply, including high-rise residential buildings, office buildings, hospitals, hotels, schools, stations, municipal buildings, warehousing and logistics centers, power facilities, chemical plants, and food factories. In these application scenarios, the pump unit not only undertakes daily fire protection tasks but may also provide some domestic water supply pressurization functions in certain buildings; therefore, its quiet operation and stability are particularly important. In summary, low-noise vertical fire pumps, with their high-efficiency hydraulic performance, low-noise structural design, stable and long lifespan, convenient installation and maintenance, and high reliability, have become highly competitive products in the upgrading of modern fire protection systems. While pursuing high standards of fire safety, it improves the quality of the building environment with lower noise, providing a fire water supply solution that balances performance and comfort for various building projects. It is a popular type of fire pump in current and future engineering projects, and will continue to develop and optimize with the advancement of the fire protection industry.