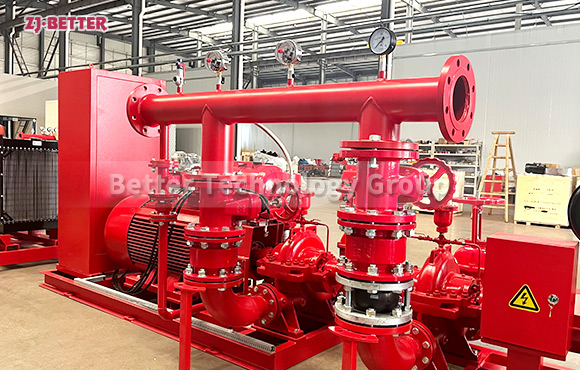

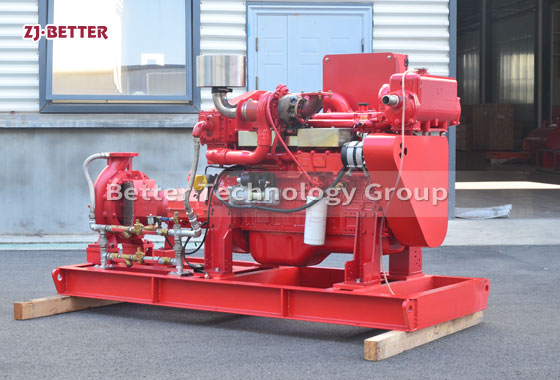

Heavy-Duty Electric Fire Pump System: Delivering High Flow and High Head for Large-Scale Fire Networks

Heavy-duty electric fire pump systems provide high flow and high head support for large fire protection networks. They have advantages such as high-efficiency motor drive, intelligent control, stable water supply and durable structure. They are suitable for high-rise buildings, industrial parks, petrochemical bases and warehousing and logistics scenarios, providing reliable and continuous water supply for complex fire protection needs.

Heavy-duty electric fire pump systems, as an indispensable key component in current high-standard fire water supply systems, are widely used in industrial parks, large commercial complexes, high-rise buildings, petrochemical bases, warehousing and logistics centers, municipal infrastructure, and high-risk areas requiring continuous fire water supply, thanks to their high flow output capacity, stable high head performance, and durable structural design. With the continuous expansion of modern building scale and the increasing complexity of internal structures, traditional fire water supply equipment can no longer meet the instantaneous pressure demands of high-rise water supply and high-density pipe networks. Heavy-duty electric fire pump systems are a high-performance solution developed to address these needs. This system uses a high-efficiency motor drive, combined with pump bodies, impellers, and bearing assemblies made of wear-resistant, high-strength materials, ensuring stable power output under long-term continuous operation and effectively reducing vibration, friction, and energy consumption. Its core technological advantage lies in maintaining stable water pressure even under high flow and high flow resistance conditions, achieving rapid water supply, long-distance delivery, and coverage of complex pipe networks, providing powerful power support for building fire protection systems. To meet the engineering needs of different projects, this system typically offers multiple configuration options, such as single-pump mode, dual-pump parallel operation, frequency conversion control, automatic switching of multiple pumps, and emergency backup systems. This allows users to flexibly match the most suitable equipment combination based on on-site flow requirements, head requirements, and installation space, while also improving overall operational efficiency. The heavy-duty electric fire pump system features a meticulously optimized structure. The motor and pump body adopt an integrated direct-drive structure, reducing mechanical energy loss, improving transmission efficiency, and significantly reducing operating noise. The pump body flow channel employs a hydraulic simulation optimization design, reducing flow losses and ensuring smoother water flow, effectively improving pump efficiency. Simultaneously, the system casing uses a corrosion-resistant coating process, maintaining long-term stability in humid, dusty, and temperature-fluctuating environments, resisting rust, corrosion, and performance degradation. This makes it suitable for long-term outdoor use or installation in harsh industrial environments. To ensure precise pressure control in large fire protection networks, the heavy-duty electric fire pump system is typically equipped with an intelligent electrical control system, including pressure sensors, flow monitoring modules, temperature recording, automatic alarm functions, motor protection devices, and remote control interfaces. Through the intelligent control cabinet, the system can automatically start and stop the main pump or standby pump based on real-time pressure data, achieving automatic pressurization, pressure stabilization, and emergency switching. In the event of a fire, even if the pressure drops rapidly, the system can instantly start the main pump and quickly output the rated water volume, buying valuable time for firefighting operations. In long-term non-fire conditions, the control system can automatically maintain the pipeline pressure, keeping the fire sprinkler system and fire hydrant network on standby, reducing manual intervention and improving system reliability. High flow rate and high head are the two core technological advantages of the heavy-duty electric fire pump system. By strengthening the impeller channel structure design, improving pump shaft strength, optimizing impeller materials, and increasing motor output power, the system can easily achieve a flow rate output of up to several hundred cubic meters per hour, while achieving a head exceeding one hundred meters in high-rise buildings, thus meeting the water supply needs of super high-rise buildings, long-distance transportation, and high-density pipeline networks. Its performance stability has also been verified through numerous engineering projects. Whether under instantaneous high-load operation, long-term continuous operation, or frequent start-stop conditions, it can maintain reliable pressure output without performance degradation due to excessive temperature rise or vibration accumulation. The system excels in safety performance, effectively preventing the escalation of operational failures through features such as overload protection, phase loss protection, overheat protection, short circuit protection, low-pressure alarm, and automatic fault switching. The control system can also connect to the building’s fire alarm system for synchronized startup; upon receiving a fire alarm signal, the pump unit can immediately respond and automatically start, ensuring the fire water supply system quickly enters a state of readiness. Some configurations also support cloud monitoring, facilitating remote viewing of operational status, energy consumption data, fault records, and real-time pressure indicators, allowing management personnel to monitor the overall health of the fire water supply system from any location. This system has a wide range of applications, particularly suitable for challenging projects with stringent fire safety requirements, long water supply distances, and high water pressure demands. For example, in heavy industrial settings such as large power plants, smelters, and petrochemical bases, the large area, long pipelines, and numerous flammable materials place extremely high demands on the reliability of fire protection systems. Large shopping malls, exhibition centers, and warehousing and logistics parks typically have high population density, requiring massive water supply volumes and reliable high water pressure in the event of a fire. High-rise buildings demand even higher pump heads, and heavy-duty electric fire pump systems can easily cover water supply heights of dozens or even hundreds of floors. Furthermore, large transportation facilities such as airports, subways, and tunnels also require this system to provide stable emergency water supply capabilities. Due to its high reliability and low maintenance characteristics, the system has relatively low operating costs, maintaining high efficiency for extended periods and reducing downtime for maintenance, ensuring the overall fire protection system is always in optimal standby condition. In terms of energy efficiency, the use of high-efficiency motors and optional variable frequency control technology enables intelligent adjustment of output power, automatically adjusting motor speed according to pressure requirements, thereby avoiding ineffective energy consumption, improving energy utilization, and extending equipment lifespan. The transportation, installation, and maintenance of heavy-duty electric fire pump systems have also been optimized and improved. The modular base design facilitates forklift handling and quick positioning for installation, while the pump body structure also allows for easy maintenance and component replacement. Its reinforced sealing structure effectively prevents leakage and extends shaft seal life. Furthermore, optimized designs for the pump body inspection port, bearing lubrication methods, and impeller disassembly and assembly structure simplify and expedite routine maintenance. In summary, the heavy-duty electric fire pump system, with its superior high flow rate, high head, high stability, and intelligent operation control, has become an irreplaceable core device in large-scale fire protection networks. Whether dealing with high-rise building water supply, maintaining pressure in high-density fire pipeline networks, or providing high-risk fire protection in industrial settings, this system provides a continuous and stable water supply guarantee with efficient and reliable performance, building a robust fire safety barrier for various key engineering projects.

管道泵(不锈钢304316L).jpg)