Key Equipment for Large-Scale Fire Protection Projects: The Efficiency of Vertical Turbine Fire Pumps

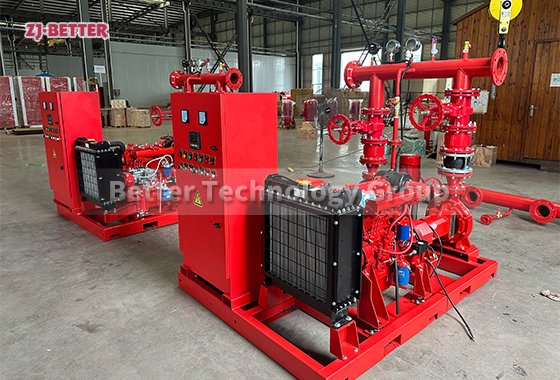

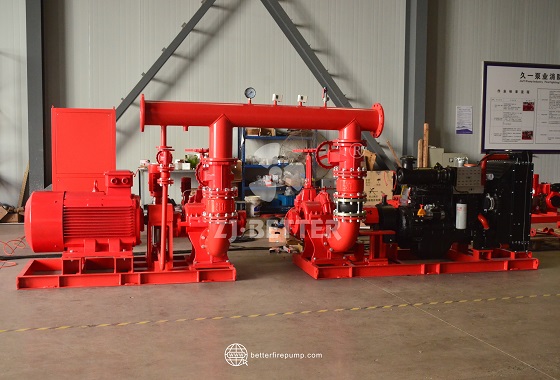

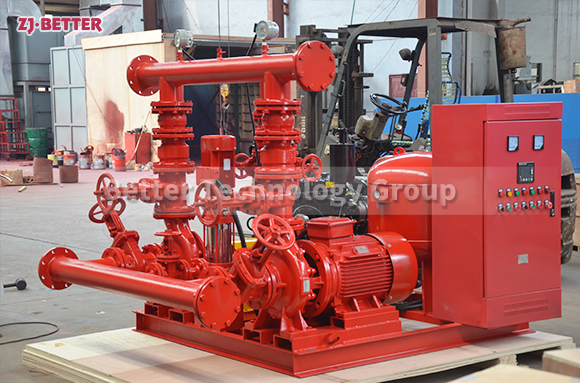

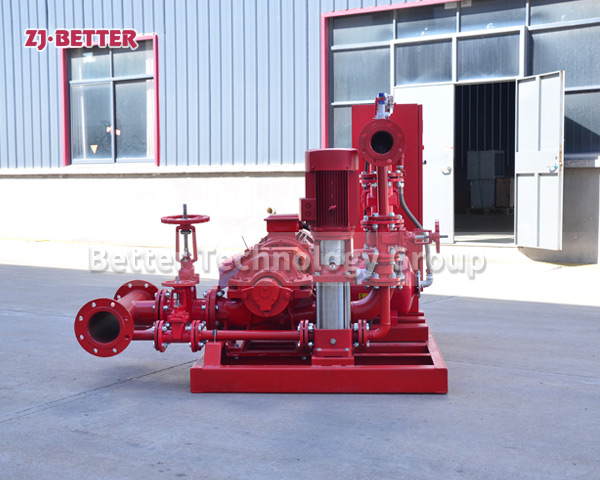

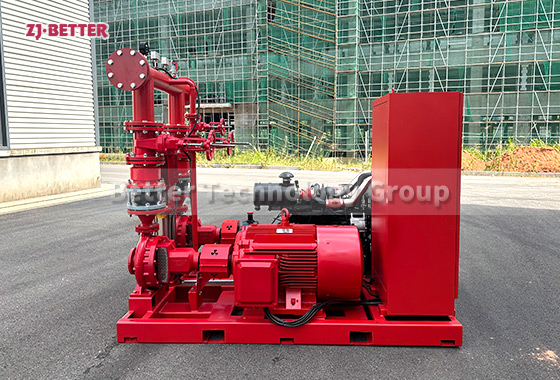

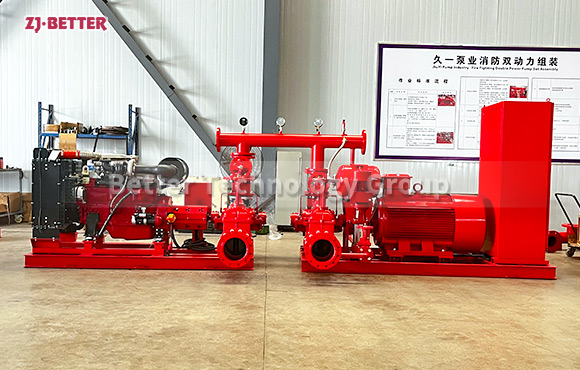

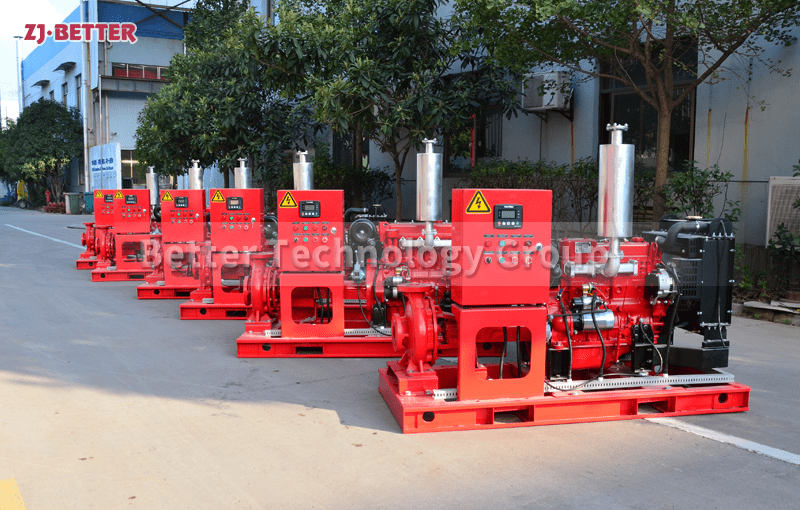

Vertical long-shaft fire pumps are known for their high head, large flow rate, and stable performance, making them suitable for high-rise buildings, industrial parks, chemical plants, ports, and deep well water intakes. They feature a compact structure, small footprint, stable operation, corrosion resistance, and easy maintenance. They can also be driven by either electric or diesel engines to ensure continuous water supply, making them an ideal choice for ensuring the efficient and safe operation of fire protection systems.

In modern large-scale fire protection engineering and industrial protection systems, the performance of fire pumps directly affects the stability and reliability of the entire water supply system. Vertical long-shaft fire pumps, with their unique structural design and powerful conveying capacity, have become key equipment for handling deep well water intake, high-lift water supply, and large-flow fire protection systems. This type of fire pump is specifically designed for applications requiring high pressure and continuous operation, and is widely used in urban fire water supply, high-rise building fire protection, industrial park fire prevention, ports, airports, chemical plants, oil depots, and large-scale water conservancy facilities. The biggest advantage of vertical long-shaft fire pumps is their ability to stably pump water from deep or low-level water sources, ensuring rapid water supply in any emergency and meeting the high-efficiency response requirements of fire protection systems. The structure of a vertical long-shaft fire pump mainly consists of a motor, drive shaft, guide bearing, delivery pipe, impeller, and pump body. It adopts a vertical installation method, with the motor located above the ground, while the pump body extends underground or into the water tank, achieving efficient conveying from low to high water levels. This design not only saves ground space but also allows the equipment to maintain stable operation in environments with significant water level fluctuations. Its impeller typically employs a highly efficient fluid dynamics optimization design, maintaining excellent hydraulic performance and energy conversion efficiency under high head and high flow conditions. The shaft system uses a multi-section drive shaft combined with guide bearings, ensuring smooth transmission, low mechanical loss, and enabling long-term continuous operation without easily generating vibration or uneven wear. Compared to ordinary centrifugal pumps, the biggest performance advantage of vertical long-shaft fire pumps lies in their extremely strong adaptability, especially in areas with limited water intake or significant elevation differences, still ensuring stable flow and pressure output. This type of pump performs exceptionally well in high-head water supply and is often used in fire protection projects where the water source is far from the pump house or where there is a significant elevation difference. Furthermore, different pump sections and impeller combinations can be designed according to specific project requirements to achieve multi-stage pressurization, ensuring that fire water supply standards are met under various complex conditions. Due to its vertical structural design, vertical long-shaft fire pumps also have significant advantages in installation and maintenance. The pump body can be directly installed in underground water tanks or deep wells without occupying excessive ground space, making it particularly suitable for urban buildings or underground projects with limited space. The motor is located on the ground, facilitating inspection and maintenance and reducing the risks and difficulties of operation in confined spaces. Its drive shaft and bearings are made of high-strength stainless steel or carbon steel, offering excellent wear and corrosion resistance, adapting to various water quality environments, and maintaining stable operation even in water sources containing trace impurities or mild corrosiveness. To improve operational reliability and safety, vertical long-shaft fire pumps are typically equipped with advanced electrical control systems and automated monitoring devices, capable of real-time monitoring of key parameters such as water pressure, flow, temperature, and bearing operating status. In case of abnormalities, the system will automatically alarm or execute a shutdown protection mechanism, ensuring the safety of the equipment and the entire fire protection system. Furthermore, this type of pump can be configured with a soft starter, frequency converter, or diesel engine drive unit according to project needs, enabling flexible switching between multiple drive modes and ensuring continuous water supply even in the event of a power outage, thereby enhancing the emergency response capability of the entire fire protection system. In terms of material selection, vertical long-shaft fire pumps are typically manufactured using high-quality cast steel, stainless steel, or bronze, possessing excellent corrosion resistance, oxidation resistance, and high-temperature resistance, effectively extending the equipment’s service life. Its mechanical seal uses imported sealing components, ensuring reliable sealing performance, preventing leakage, and guaranteeing long-term operational stability and safety. The bearings employ self-lubrication or external lubrication, resulting in low operating noise, low friction, and low temperature rise, further improving the pump’s overall efficiency and service life. The value of vertical long-shaft fire pumps in fire protection systems lies not only in their performance but also in their economy and maintainability. Because the pump body is constantly immersed in water, it avoids the mechanical wear and seal damage caused by dry running in traditional pumps, resulting in longer overall maintenance cycles and lower operating costs. Furthermore, its modular design facilitates easy disassembly and assembly of components and quick replacement of parts, significantly reducing maintenance difficulty and downtime. For large industrial projects, petrochemical bases, and urban fire protection systems, vertical long-shaft fire pumps are an ideal choice for achieving efficient water supply and emergency fire protection. They can establish system pressure and continuously supply water in a very short time, maintaining stable output even under high load conditions, ensuring the simultaneous operation of multiple components such as fire sprinkler systems, fire hydrant systems, and water cannon systems. Its high head and large flow rate design can meet the water intake needs from various sources such as deep wells, pools, and rivers, providing a continuous and reliable fire-fighting water supply for large building complexes and industrial facilities. Performance test data shows that the vertical long-shaft fire pump has an efficiency of over 80% under rated operating conditions, with a head ranging from 100 to 300 meters depending on the configuration, and a flow rate range covering 100 to 2000 cubic meters per hour, fully complying with international fire protection standards. This performance level not only reflects its advanced structural and hydraulic design but also ensures strong and stable hydraulic support in critical moments. In summary, the vertical long-shaft fire pump, with its multiple advantages such as high efficiency, stability, durability, energy saving, and safety, has become an indispensable core equipment in modern fire protection engineering systems. Whether dealing with the high-pressure water supply needs of high-rise buildings or meeting the emergency fire-fighting requirements of large industrial facilities, it demonstrates excellent performance and reliability. With the continuous development of intelligent control and energy-saving technologies, vertical long-shaft fire pumps are upgrading towards greater efficiency, intelligence, and environmental protection. Their application prospects in future fire protection systems will be even broader, providing solid safety guarantees and continuous power for various fire protection projects worldwide.