Precision Water Delivery: The Key Role of Vertical Inline Fire Pumps in Building Fire Systems

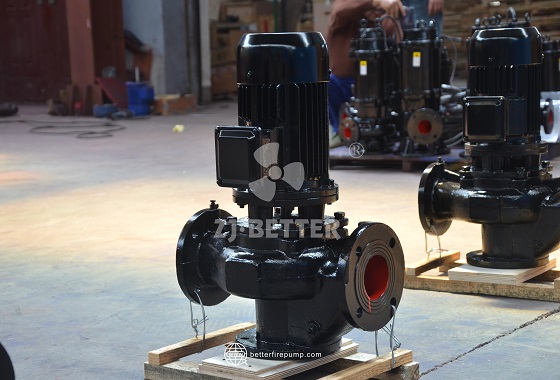

Vertical pipeline fire pumps have the advantages of high head, large flow rate and energy-saving operation. They are compact in structure and easy to install, and are suitable for high-rise buildings, industrial plants and fire protection systems, providing stable and efficient fire protection solutions for various emergency water supply sites.

In modern urban building fire protection systems, fire pumps are the core equipment of the entire water supply system. Among them, vertical inline fire pumps, with their compact structural design, high-efficiency operation, and excellent reliability, have become an indispensable component in high-rise buildings, commercial complexes, industrial plants, and public facilities. With the continuous improvement of fire safety standards and the increasing complexity of building structures, higher requirements are placed on the stability, response speed, and energy-saving performance of fire protection systems. Vertical inline fire pumps, with their unique design concept and advanced manufacturing process, significantly improve the overall efficiency and safety level of the fire water supply system while ensuring its continuous and reliable operation. Vertical inline fire pumps adopt a vertical structural design, occupying a small area and facilitating installation. They can be directly connected to the piping system, achieving an “integrated pump and pipe” layout. This structural advantage is particularly prominent in high-rise buildings or underground machine rooms with limited space, saving installation space, effectively simplifying pipeline layout, and reducing engineering construction complexity. At the same time, the coaxial direct connection design of the pump body and motor makes energy transfer more direct, reduces mechanical losses, and ensures smoother operation, significantly reducing vibration and noise, thereby extending equipment life and reducing maintenance needs. Its highly efficient hydraulic model has been optimized multiple times, enabling high flow and high head output under low energy consumption conditions. This ensures that in any sudden fire, the fire water supply system can quickly provide sufficient pressure and flow to meet the needs of sprinkler systems, fire hydrant systems, and other fire terminals in multi-story buildings.

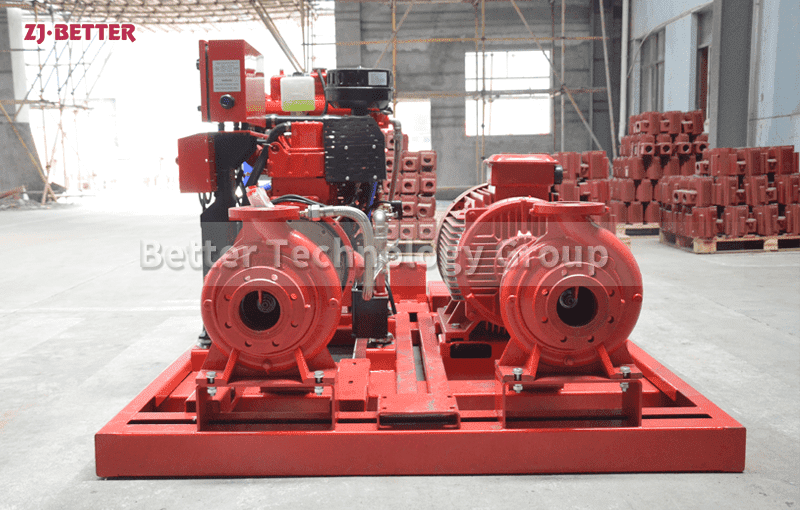

In terms of performance, the vertical pipeline fire pump is designed to fully consider the stringent requirements of fire protection systems for the continuity and stability of water supply. The equipment is typically manufactured using high-temperature and corrosion-resistant materials, enabling long-term stable operation in complex environments such as high-temperature, humid, or impurity-containing water sources. The shaft seal structure uses mechanical seals or double-end face seals to effectively prevent leakage and ensure excellent sealing performance of the pump body under high-pressure operating conditions. Furthermore, the pump shaft undergoes precision machining and dynamic balancing to ensure concentricity of rotating parts during high-speed operation, reducing wear and noise, thus maintaining high efficiency during long-term continuous operation. Its motor uses a high-efficiency, energy-saving motor with fast start-up response, low operating temperature rise, and excellent overload protection and insulation performance, ensuring stable and reliable operation under sudden high-load conditions and providing solid power support for the fire water supply system. In high-rise buildings, fire-fighting water supply systems often need to cope with high head and complex pipe network resistance. The high-head design of vertical inline fire pumps easily meets high-pressure water supply demands. Through scientific impeller curve design and fluid dynamics optimization, the water flow channels inside the pump body are smoother, energy loss is lower, and efficiency is significantly improved. Simultaneously, the pump maintains a stable flow output during operation, preventing interruptions or uneven flow in the sprinkler system due to pressure fluctuations, thus effectively ensuring the continuity and reliability of fire-fighting operations. In emergencies, the response speed of the fire-fighting system is crucial. The design of vertical inline fire pumps ensures rapid start-up and instantaneous establishment of rated pressure, ensuring that fire-fighting water can be delivered to key points as quickly as possible, gaining valuable rescue time.

In addition to its powerful performance, vertical inline fire pumps also possess excellent energy-saving advantages. Utilizing advanced hydraulic models and high-efficiency motors, its overall energy efficiency is more than 10% higher than traditional horizontal or split pumps, significantly reducing energy consumption and operating costs over the long term. The efficient operation of the equipment not only reduces energy waste but also aligns with modern green building and sustainable development concepts. Meanwhile, its modular design makes maintenance and repair more convenient. Users can quickly replace vulnerable parts such as impellers and shaft seals according to their needs without complete disassembly, significantly reducing maintenance costs and downtime.

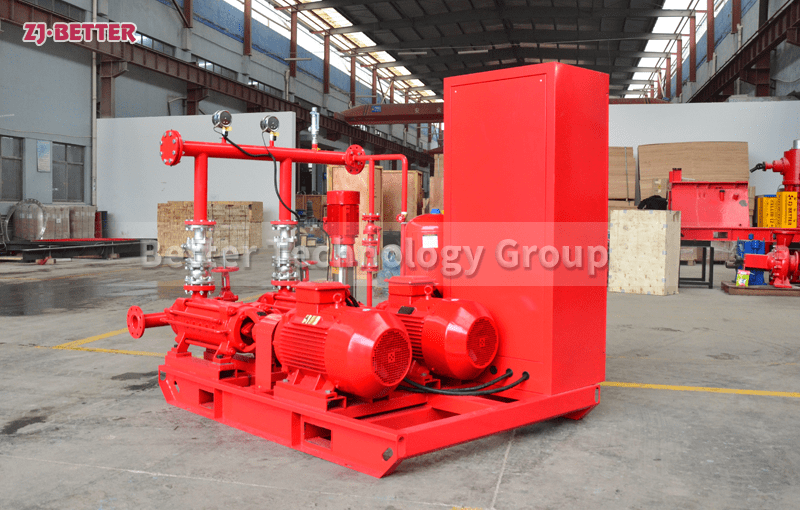

From a system integration perspective, vertical inline fire pumps can seamlessly interface with intelligent control systems, supporting automatic start/stop, pressure monitoring, fault alarms, and remote linkage, meeting the technical requirements of modern building intelligent fire protection systems. Through the collaborative work of the control cabinet and sensor system, real-time monitoring and dynamic adjustment of the pump can be achieved, ensuring constant water pressure and stable operation. In case of abnormalities, it automatically switches to a backup pump or issues an alarm, greatly improving system safety and reliability. In complex building fire protection networks, this automated and intelligent control mode not only improves emergency response capabilities but also provides higher visualization and management efficiency for system operation and maintenance.

In terms of application scenarios, vertical inline fire pumps are widely used in fire water supply systems in high-rise buildings, underground parking lots, airport terminals, subway stations, industrial plants, warehousing and logistics centers, hospitals, and schools. Its flexible adaptability and multiple model configurations allow for the selection of appropriate flow and head parameters to meet the needs of different projects, ensuring that the fire water supply system maintains optimal operating conditions under various circumstances. Especially in high-rise buildings, vertical pumps effectively handle the challenges of high-pressure water supply, performing exceptionally well in multi-stage zoned water supply systems. This ensures stable water pressure for sprinkler heads and fire hydrants on each floor, providing a solid guarantee for fire safety.

Furthermore, the pump’s overall protective performance is outstanding. The pump body surface uses a corrosion-resistant spray coating process, effectively resisting erosion from humidity, salt spray, and chemically corrosive environments, ensuring that the equipment does not rust or scale during long-term operation. For projects with special requirements, stainless steel or copper alloy materials can be selected to further enhance corrosion resistance and wear resistance. During long-term use, vertical pipeline fire pumps not only maintain stable performance but also have long maintenance cycles and high reliability, making them truly cost-effective fire water supply equipment.

In summary, vertical in-line fire pumps, with their compact structure, convenient installation, high efficiency, energy saving and environmental protection, intelligent control, and high reliability, have become one of the most representative core equipment in modern building fire protection systems. Whether in new construction projects or the renovation of existing systems, they provide a continuous, safe, and reliable water supply to the fire protection system with their superior performance and stable output, ensuring the strongest defense for personnel and property safety in critical moments. With the continuous advancement of building fire protection technology and increasingly stringent safety standards, vertical in-line fire pumps will continue to play an irreplaceable role in the fire protection field, providing efficient and reliable solutions for fire safety in buildings worldwide.