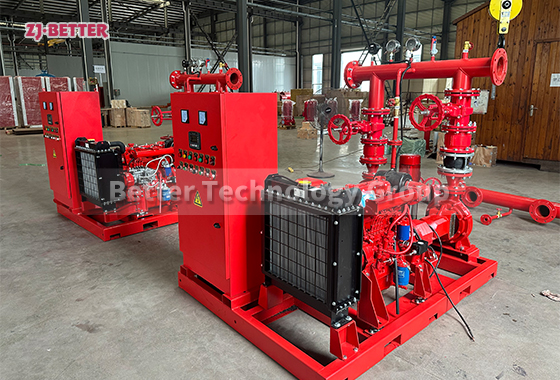

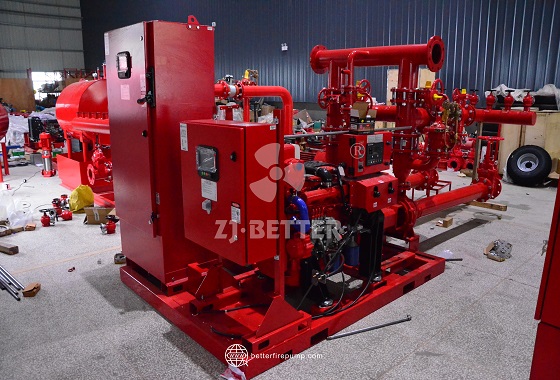

Compact Structure with Strong Power: The Ideal Choice of Modular Fire Pump Station

Discover the advantages of modular fire pump stations with compact structure and powerful performance. Ensure reliable water supply, space-saving installation, energy efficiency, and intelligent control for modern fire protection systems.

Fire pump stations have always played a vital role in the fire safety systems of modern buildings and industrial facilities. With the continuous advancement of technology, modular fire pump stations have gradually become an ideal choice in the market. Their unique compact structure and powerful power not only improve overall operational reliability and efficiency, but also significantly reduce the complexity of installation and maintenance. Compared with traditional fire pump stations, modular designs offer significant advantages in space utilization, performance, and intelligent control. They are particularly suitable for scenarios with limited space, tight construction schedules, or strict operational requirements. Their core advantage lies first in their compact structure. Modular fire pump stations typically adopt an integrated layout, integrating the main pump, backup pump, pressure-stabilizing pump, control system, piping, and valves into a prefabricated frame. This integrated design effectively saves space and enables flexible deployment in high-rise buildings, underground machine rooms, or industrial plants, ensuring efficient installation and operation even in limited space. Furthermore, the modular structure facilitates transportation and lifting, reducing on-site assembly and adjustment steps, significantly shortening the construction period, and saving valuable time and costs for project construction. In terms of performance, modular fire pump stations demonstrate robust and stable power output. Their high-performance main pumps can quickly start and provide sustained, sufficient water pressure in the event of a fire, ensuring efficient operation of the sprinkler and fire hydrant systems. The presence of backup pumps provides redundancy, ensuring an uninterrupted water supply even in the event of an unexpected main pump shutdown, significantly enhancing system reliability and safety. A pressure-stabilizing pump maintains stable pipe network pressure during daily operation, avoiding energy waste and equipment wear caused by frequent starts and stops of the main pumps, thereby extending the life of the entire system and reducing operating costs. Furthermore, modular fire pump stations are typically equipped with advanced electronic control systems, enabling fully automatic start-stop and intelligent switching. These systems automatically select the appropriate pump group based on pressure fluctuations and feature multiple alarm and protection features, such as overload protection, phase loss protection, overpressure alarms, and low water level alarms, ensuring safe operation under various operating conditions. This intelligent control approach not only reduces the need for manual intervention but also speeds up emergency response, enabling the fire protection system to be operational immediately at critical moments. Modular fire pump stations also offer significant advantages in terms of energy conservation and environmental protection. Their optimized pump unit configuration and intelligent control strategies adjust operating conditions based on actual water demand, avoiding unnecessary energy consumption and achieving efficient and energy-efficient operation. Furthermore, their compact structure and rational design result in minimal vibration and noise during operation, making them particularly suitable for deployment in environments with stringent noise control requirements, such as hospitals, schools, and commercial complexes. Their efficient energy utilization and low-noise operation not only align with the trend of modern green buildings but also help businesses and projects reduce long-term operating costs. Another key advantage of modular fire pump stations is their ease of maintenance and management. Their integrated design streamlines the layout of components and streamlines piping, facilitating routine inspections and maintenance while reducing the complexity of troubleshooting. Furthermore, the standardized modular configuration allows for rapid component replacement and upgrades, avoiding lengthy downtime and ensuring the fire protection system remains highly efficient and available. For locations with stringent fire safety requirements, such as large industrial parks, petrochemical bases, data centers, and transportation hubs, modular fire pump stations provide a stable and reliable water supply. Their exceptional adaptability and flexibility allow for customized configurations tailored to meet diverse application requirements. Whether for a single building or a large fire protection network, modular fire pump stations offer an efficient, stable, and sustainable solution. Overall, with their compact structure, powerful power, intelligent control, energy-efficient operation, and easy maintenance, modular fire pump stations have become an ideal choice for modern fire protection systems. They not only enhance the safety and reliability of the overall fire water supply system but also meet today’s diverse demands for safety, environmental protection, and efficiency in an efficient and flexible manner. With accelerating urbanization and the continuous expansion of building construction, modular fire pump stations are poised to play an even more crucial role in future fire protection, providing a solid foundation for the safety of life and property.