What occasions are the fire pump sets used for?

Fire pump sets are often required when the local water system cannot provide sufficient pressure to meet the design hydraulic requirements of the fire sprinkler system. This typically occurs in multi-story buildings or systems that require relatively high terminal pressures at fire sprinklers in order to release large volumes of water, such as storage warehouses. A fire pump is also required if the water supply is provided from above-ground or underground storage tanks.

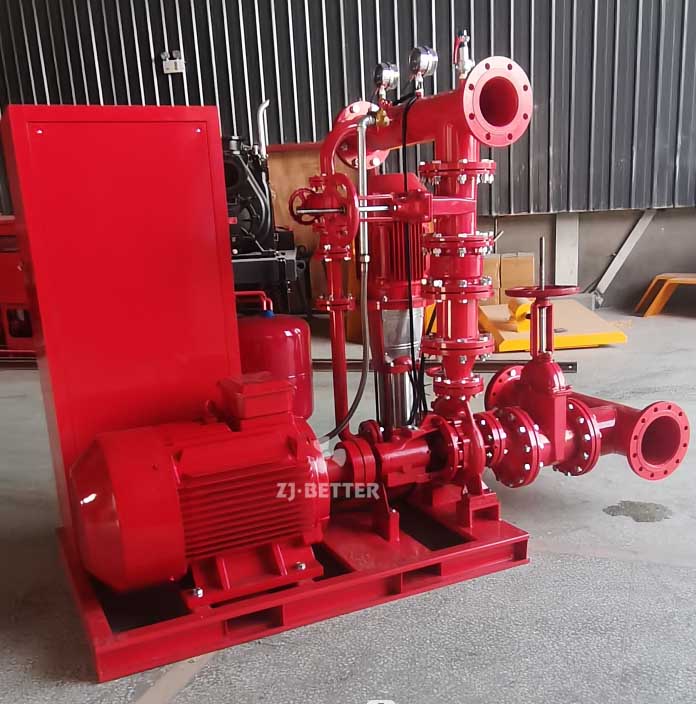

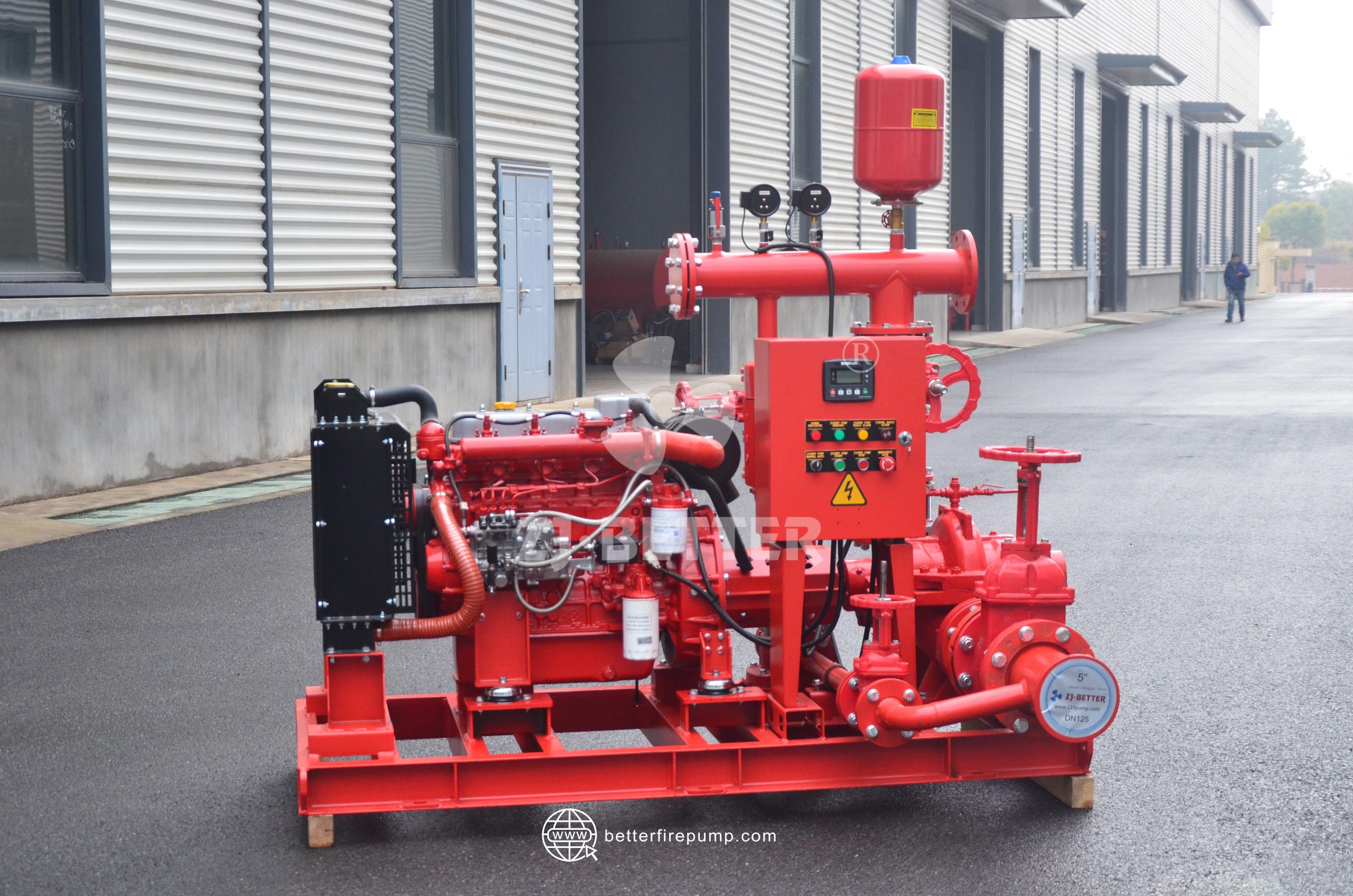

An important part of the water supply for a fire sprinkler system is the fire pump. It can be powered by electricity, diesel or steam. The pump inlet is connected to a public groundwater supply or static water source such as a tank, reservoir or lake. Pump sets provide higher pressure water flow to sprinkler system risers and hose risers.

When the pressure in the fire sprinkler system falls below the baseline, the fire pump is activated. Triggered when one or more fire sprinklers are exposed to heat above the design temperature; the sprinklers open and release water.